Pull-type metal wall surface working wall-climbing robot

A wall-climbing robot and traction technology, applied in the field of robotics, can solve the problems of small load capacity and poor obstacle-crossing ability, and achieve the effects of large load capacity, reliable adsorption, and increased adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

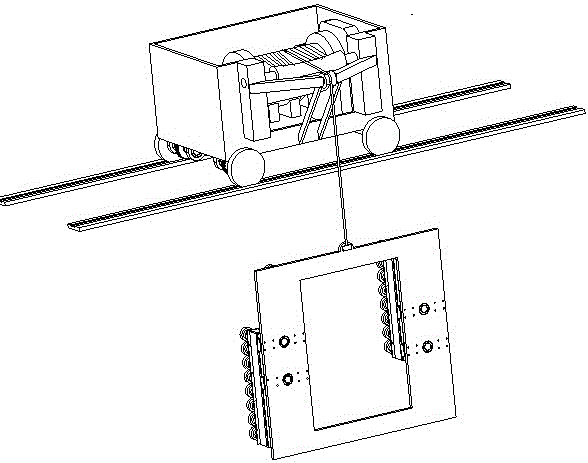

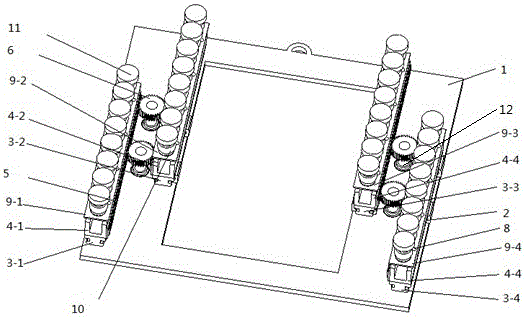

[0023] Such as Figure 1 to Figure 4 As shown, a traction-type metal wall-climbing robot includes a traction mechanism and a crawling mechanism, and the traction mechanism suspends the crawling mechanism on the metal wall through a traction rope.

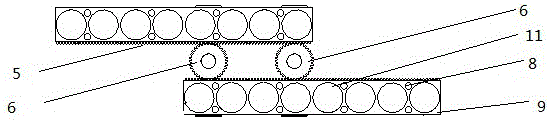

[0024] The crawling mechanism includes a frame 1, a fixed slider 2, a linear guide rail 3, a support frame 4, a rack 5, a gear 6, a linear motor 7, a support column 8, a support plate 9, a ball joint 10, an electromagnet 11, and a drive shaft 12. Eight fixed sliders 2 are installed on the left and right frames of the frame 1, and every two fixed sliders 2 form a group, and cooperate with a linear guide rail 3, so that the linear guide rail 3 can slide along the fixed slider 2 , the left and right frames of the frame 1 have two linear guide rails 3 installed in parallel; two transmission shafts 12 are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com