High pressure rust cleaning device and method of hydraulic pipe fittings

A hydraulic pipe and high-pressure technology, which is applied in the field of high-pressure rust removal devices for hydraulic pipe fittings, can solve problems such as pipe wall stress defects, damage to overall equipment, and pipe fitting damage, and achieve the effect of improving rust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

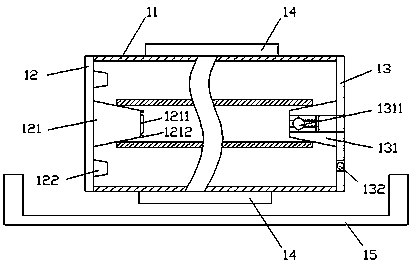

[0026] Embodiment 1 Installation: Fix both ends of the inner hole of the hydraulic pipe fitting between the tapered nozzle 121 and the ejector pin 131, push the ejector pin 131 to clamp the hydraulic pipe fitting, and close the rear cover 13;

[0027] Liquid injection: heat the descaling liquid to 50℃, and inject it from the descaling liquid tank 2 through the large nozzle hole 1211 and the small nozzle hole 1212 of the nozzle 121 into the inner wall of the hydraulic pipe fitting to clean the inner wall of the pipe; at the same time, it is injected into the cylinder through the auxiliary nozzle 122 Clean the outer wall of hydraulic pipe fittings;

[0028] Soaking and flushing: the pipe fittings are soaked and flushed for 7 minutes; during this process, the pressure in the cylinder body 11 and the hydraulic pipe fittings are respectively adjusted through the auxiliary drain hole 132 and the drain hole 1311;

[0029] Take the parts, open the back end cover 13, push the thimble 131 to l...

Embodiment 2

[0030] Embodiment 2: Installation and pickup will not be repeated:

[0031] Liquid injection: heat the descaling liquid to 55℃, and inject it from the descaling liquid tank 2 through the large orifice 1211 and the small orifice 1212 of the nozzle 121 into the inner cavity of the hydraulic pipe to clean the inner wall of the pipe; at the same time, it is injected into the cylinder through the auxiliary nozzle 122 Clean the outer wall of hydraulic pipe fittings;

[0032] Soaking and flushing: The pipe fittings are soaked and flushed for 6 inches; during this process, the pressure in the cylinder body 11 and the hydraulic pipe fittings is adjusted through the auxiliary drain hole 132 and the drain hole 1311 respectively.

Embodiment 3

[0033] Embodiment 3: Installation and pickup will not be repeated:

[0034] Liquid injection: heat the descaling liquid to 60℃, and inject it from the descaling liquid tank 2 through the large nozzle hole 1211 and the small nozzle hole 1212 of the nozzle 121 into the inner cavity of the hydraulic pipe to clean the inner wall of the pipe; at the same time, it is injected into the cylinder through the auxiliary nozzle 122 Clean the outer wall of hydraulic pipe fittings;

[0035] Soaking and flushing: the pipe fittings are soaked and flushed for 5 minutes; in this process, the pressure in the cylinder body 11 and the hydraulic pipe fittings are adjusted through the auxiliary drain hole 132 and the drain hole 1311 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com