Overturning grinding rust removal device for metal plate

A metal plate and flip-type technology, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of high labor intensity, difficult metal plate cleaning, and low grinding efficiency, so as to improve work efficiency and clamping speed Fast and efficient rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

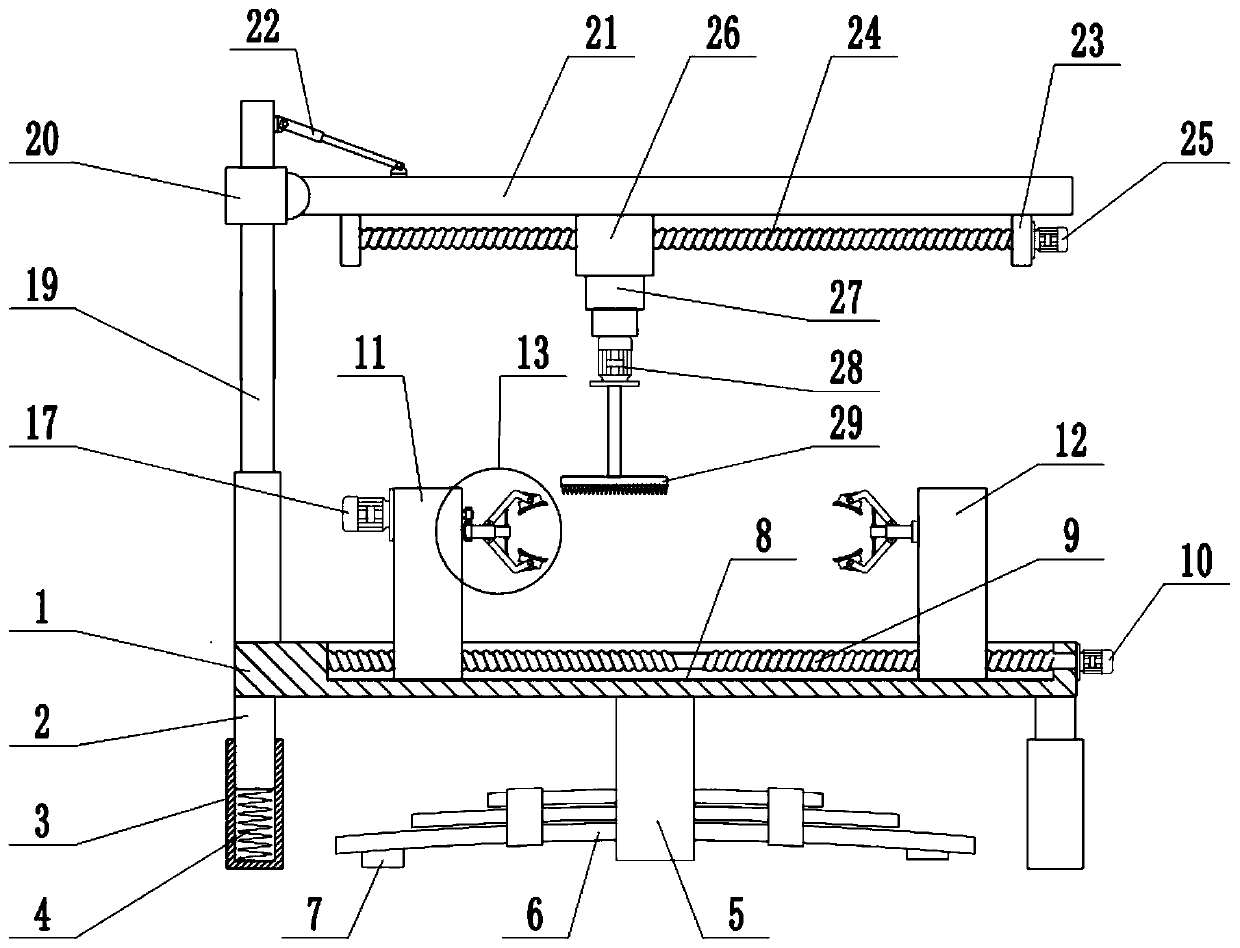

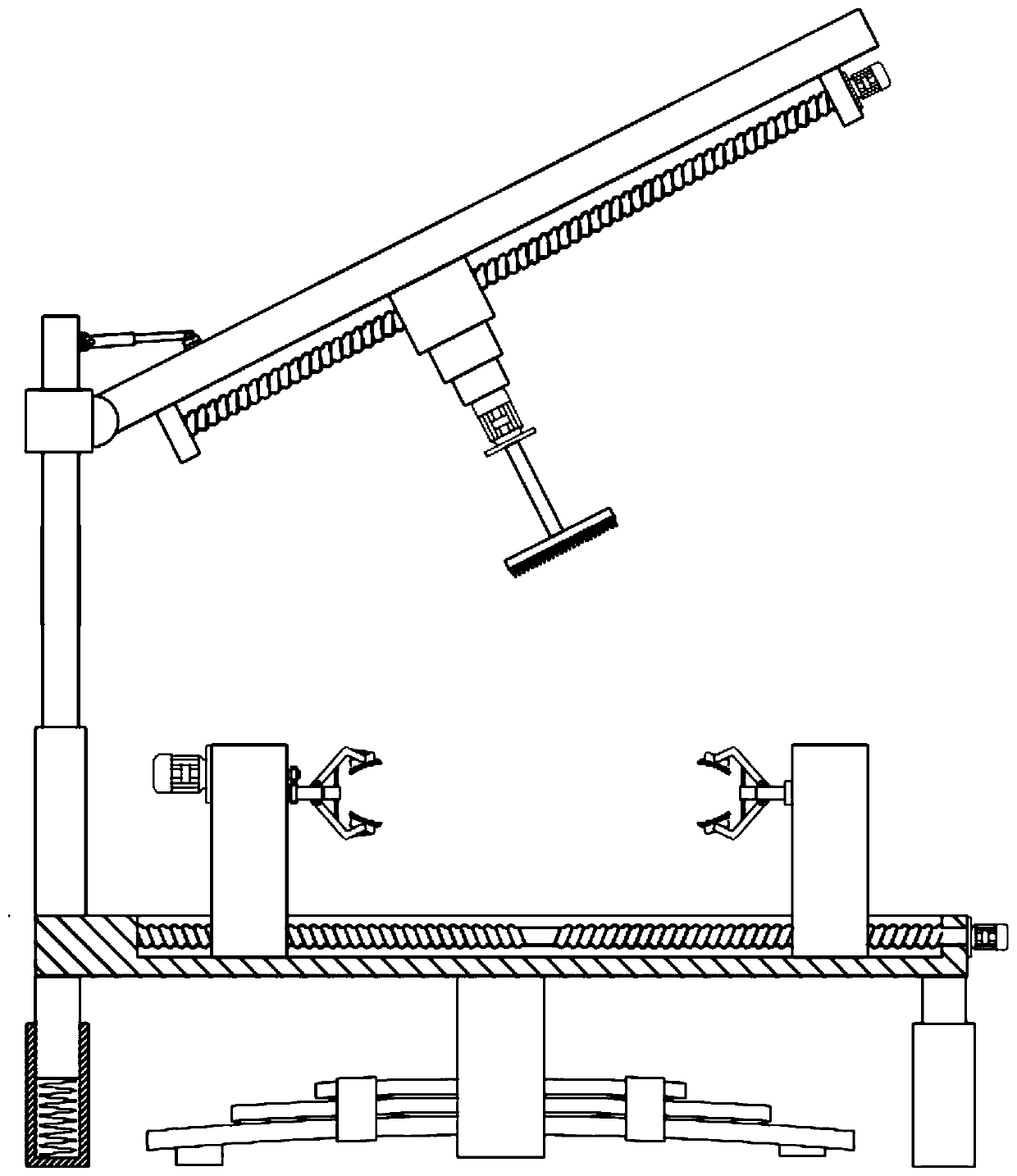

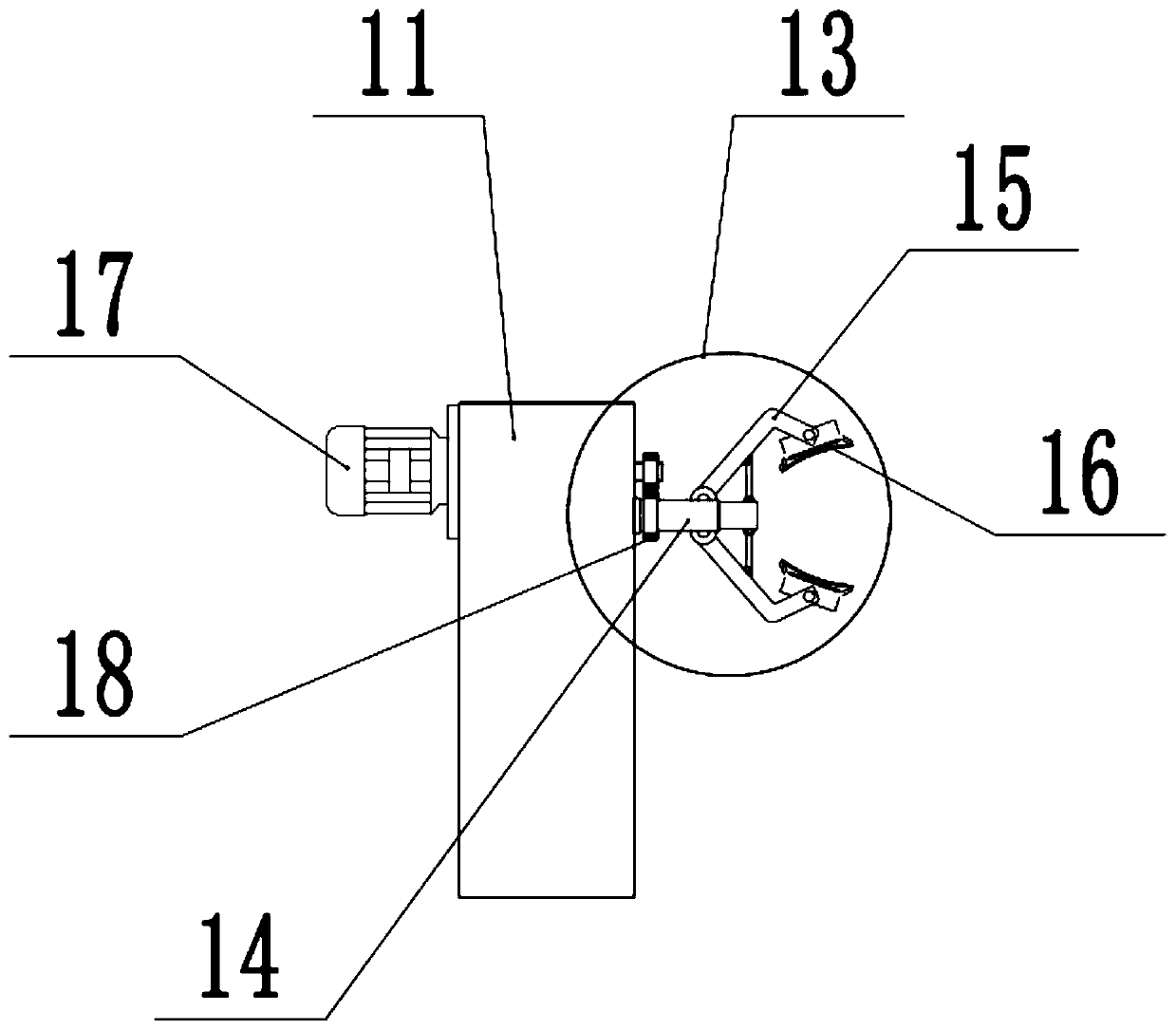

Embodiment 1

[0022] see Figure 1-4 , in an embodiment of the present invention, a flip-type metal plate grinding and derusting device includes a workbench 1, a left clamping block 11, a right clamping block 12 and a derusting brush plate 29. The upper surface of the workbench 1 is provided with a slide Groove 8, the inside of chute 8 is equipped with two-way screw mandrel 9, and the left and right ends of two-way screw mandrel 9 are respectively connected with the inner wall of chute 8 in rotation, and the outer wall of workbench 1 is fixedly connected with clamping motor 10, and clamping motor 10 is a forward and reverse motor, and the clamping motor 10 is rotationally connected with the end of the two-way screw mandrel 9. The two-way screw mandrel 9 is covered with a left clamping block 11, a right clamping block 12, a left clamping block 11, and a right clamping block. The left and right clamping blocks 12 are symmetrically arranged, the lower ends of the left clamping block 11 and the...

Embodiment 2

[0024] On the basis of Embodiment 1, a shock absorbing mechanism is installed on the lower surface of the workbench 1, and the shock absorbing mechanism includes a foot 2, a sleeve 3, a spring 4, a fixed frame 5, and a leaf spring 6, and the lower surface of the workbench 1 is fixedly connected There is a leg 2, the lower end of the leg 2 is covered with a sleeve 3, the leg 2 is slidably connected with the sleeve 3, the leg 2 can slide up and down in the sleeve 3, a spring 4 is installed inside the sleeve 3, and the upper end of the spring 4 is connected to the The legs 2 abut, the lower end of the spring 4 abuts against the bottom of the sleeve 3, the lower surface of the workbench 1 is fixedly connected with a fixed frame 5, the fixed frame 5 is fixedly connected with a leaf spring 6, and the two ends of the leaf spring 6 are installed with The support block 7 can play a certain damping effect by using the spring 4 and the leaf spring 6 to reduce the vibration generated when ...

Embodiment 1、 Embodiment 2

[0025] In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: place the metal plate between the left clamping block 11 and the right clamping block 12, control the positive and negative rotation of the clamping motor 10, and adjust the left clamping block 11 1. The distance between the right clamping blocks 12 is to adapt to metal plates of different lengths, and the shortening of the first telescopic mechanism 14 is controlled to drive the two jaws 15 to close together, and the clamping plate 16 is used to clamp the metal plate to keep the metal plate fixed , clamping speed is fast, has improved work efficiency, starts derusting motor 28, drives derusting brush plate 29 to rotate, controls the 4th telescopic mechanism 27 elongation, drives derusting brush plate 29 to move downwards, makes derusting brush plate 29 Connect with the upper surface of the metal plate, carry out the derusting operation to the upper surface of the rust r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com