Grinding rust-removal device for processing surfaces of steel bars

A steel bar processing and steel bar technology, which is applied in the field of steel bar processing surface grinding and derusting devices, can solve problems such as unfavorable steel bar derusting efficiency, and achieve the effect of improving derusting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

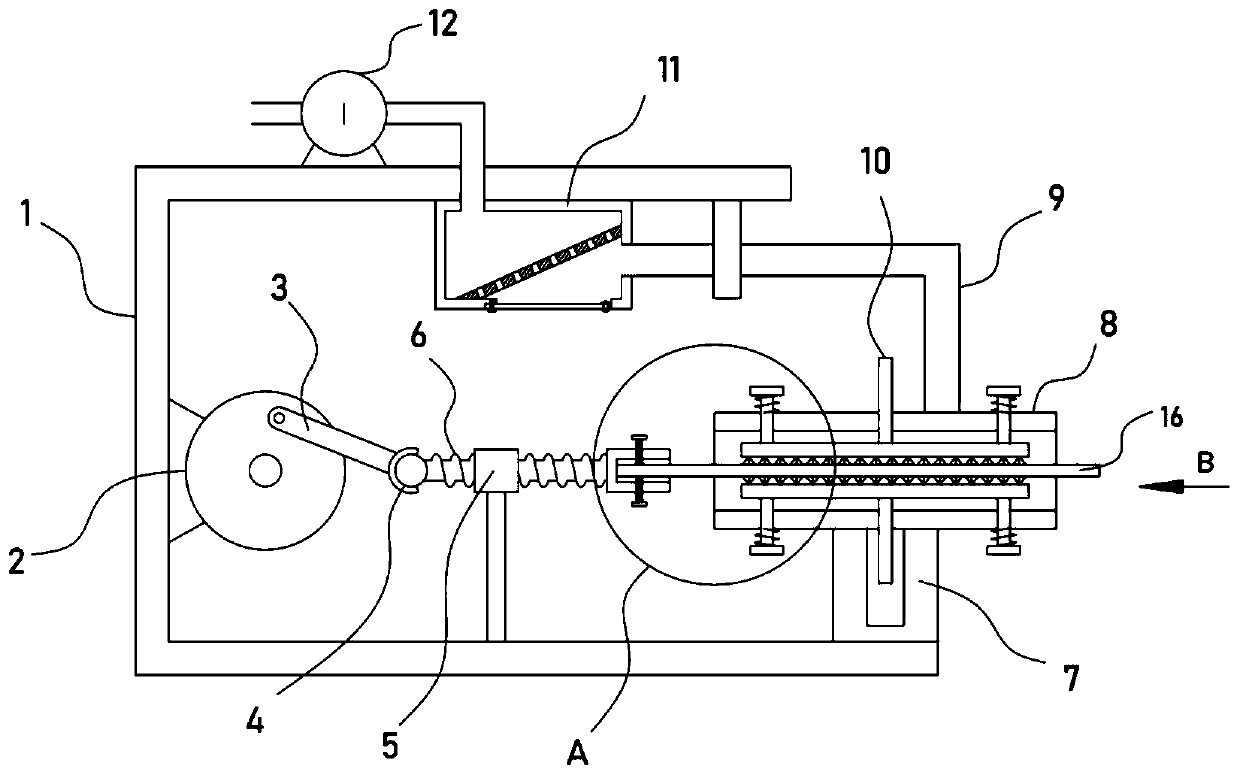

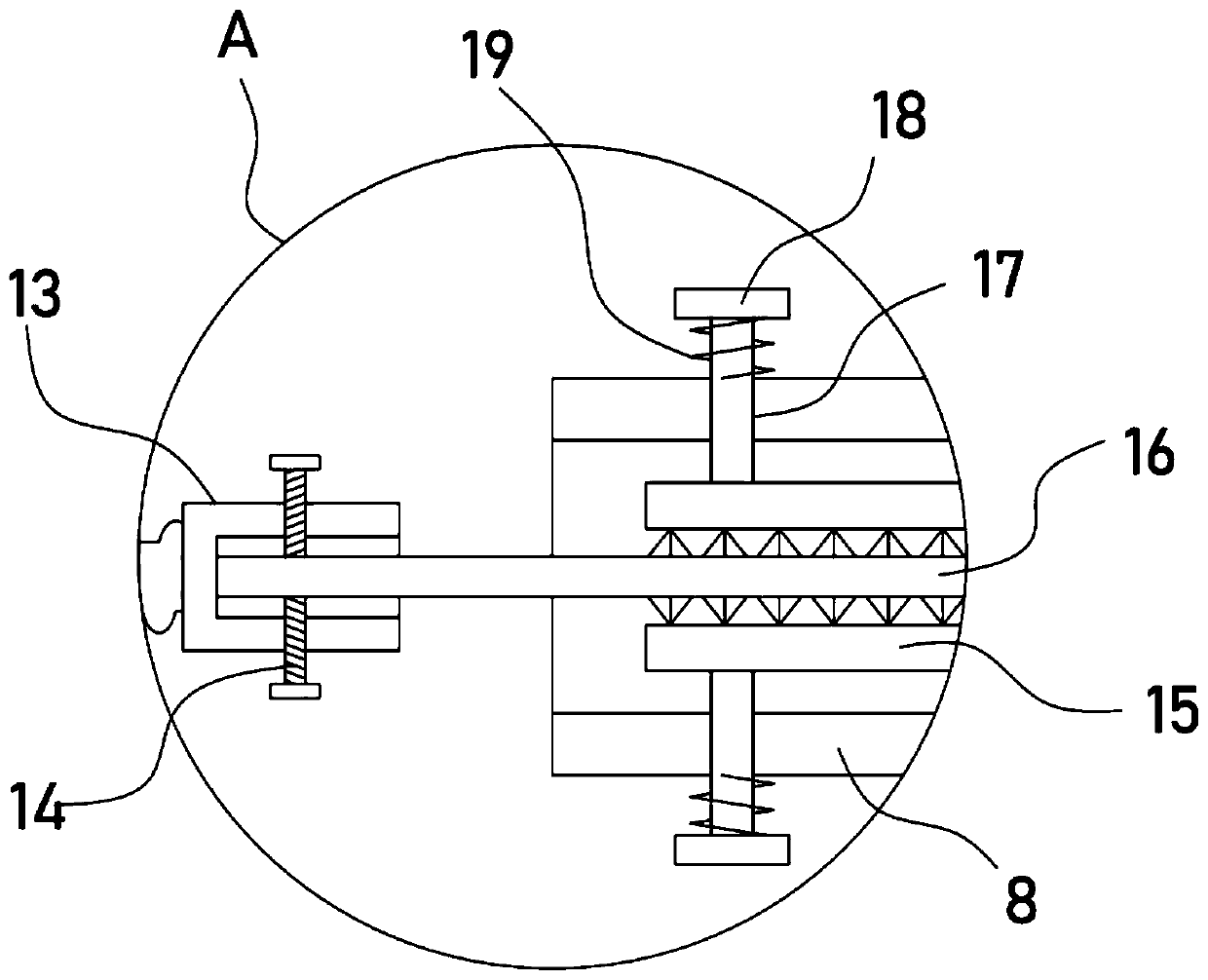

[0023] see Figure 1-5 , a steel bar processing surface grinding and derusting device, comprising a frame 1, a support frame 7 is vertically fixed on the frame 1, a grinding sleeve 8 for steel bars 16 to penetrate is fixed on the support frame 7, and the grinding sleeve 8 is internally symmetrical Two arc-shaped grinding plates 15 for grinding steel bars 16 are provided, and the adjusting mechanism for adjusting the longitudinal movement of the arc-shaped grinding plates 15 is provided on the grinding sleeve 8. The rotating wheel 2 is provided on the frame 1, and the rotating A drive rod 3 is eccentrically hinged on the wheel 2, and one end of the drive rod 3 away from the runner 2 is connected with a clamping mechanism for clamping the steel bar 16 through a screw-in mechanism.

[0024] The steel bar 16 passes through the set grinding sleeve 8, and the adjustment mechanism inside the grinding sleeve 8 adjusts the arc-shaped grinding plate 15 to make it move longitudinally, th...

Embodiment 2

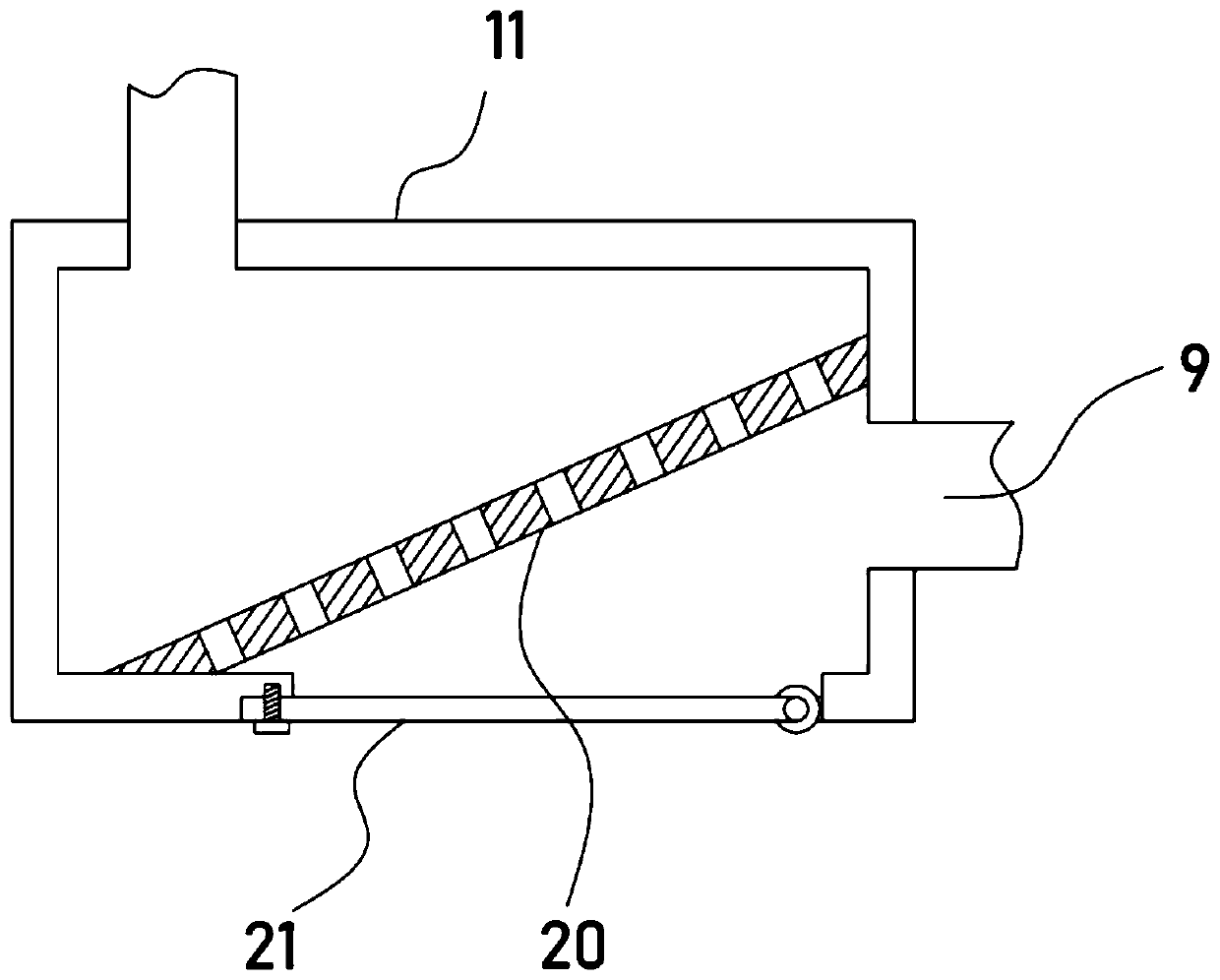

[0030] On the basis of Embodiment 1, due to the different diameters of steel bars 16 that need to be polished and derusted, in order to improve the scope of application of the device, an adjustment mechanism is also provided, which specifically includes two symmetrical bars that are slidably connected with the grinding sleeve 8. The L-shaped adjusting rod 10 is provided, and the adjusting rod 10 is connected with the arc-shaped grinding plate 15 through a reset mechanism. The opposite sides of the two adjusting rods 10 are vertically fixed with adjusting sleeves 22, and the two adjusting sleeves 22 are threaded respectively. It is connected with a threaded post 23 with opposite thread direction and fixed coaxially, and a threaded post handwheel 24 is sleeved and fixed on the threaded post 23 .

[0031] Through the above setting, when the handwheel 24 is rotated in the forward direction, the two coaxially fixed threaded columns 23 can be driven to rotate at the same time. Since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com