Hydraulic engineering construction pipeline rust removal device

A water conservancy project and pipeline technology, which is applied in the direction of explosion generating devices, manufacturing tools, metal processing equipment, etc., can solve the problems of water pipeline modification and affecting service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

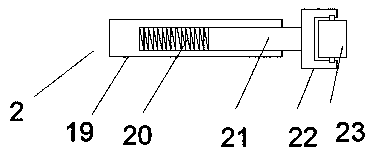

[0021] As a preferred embodiment of the present invention, the sliding device 2 includes a sleeve rod 19 and an inner rod 21 disposed inside the sleeve rod 19 and slidably connected thereto, the inner rod 21 is connected to the sleeve rod 19 through a spring 20, The end of the inner rod 21 is connected with a roller 23 through a bracket 22 .

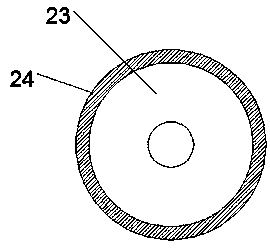

[0022] As a preferred embodiment of the present invention, the surface of the roller 23 is provided with an anti-slip layer 24, and the anti-slip layer 24 is made of soft rubber material.

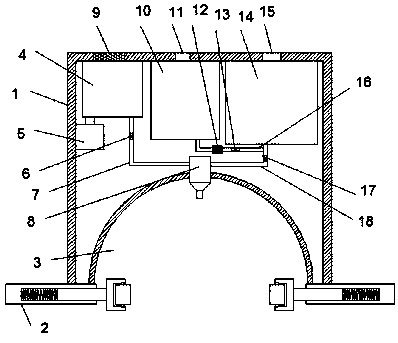

[0023] As a preferred embodiment of the present invention, a first solenoid valve 6 is provided on the gas delivery pipe 7, a second solenoid valve 13 is provided on the water delivery pipe 16, and a third electromagnetic valve 6 is provided on the sand delivery pipe 18. valve 17.

[0024] As a preferred embodiment of the present invention, the water delivery pipe 16 is provided with a water pump 12 .

[0025] In this derusting device, an air compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com