Leveling machine, black strip acid-free derusting device using the same and method thereof

A technology of hot-rolled strip steel and tempering mills, applied in the field of tempering mills, can solve the problems of ineffective removal of iron scale, poor cleaning quality, and low service life, so as to increase the price and utilization rate, increase the service life, and reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

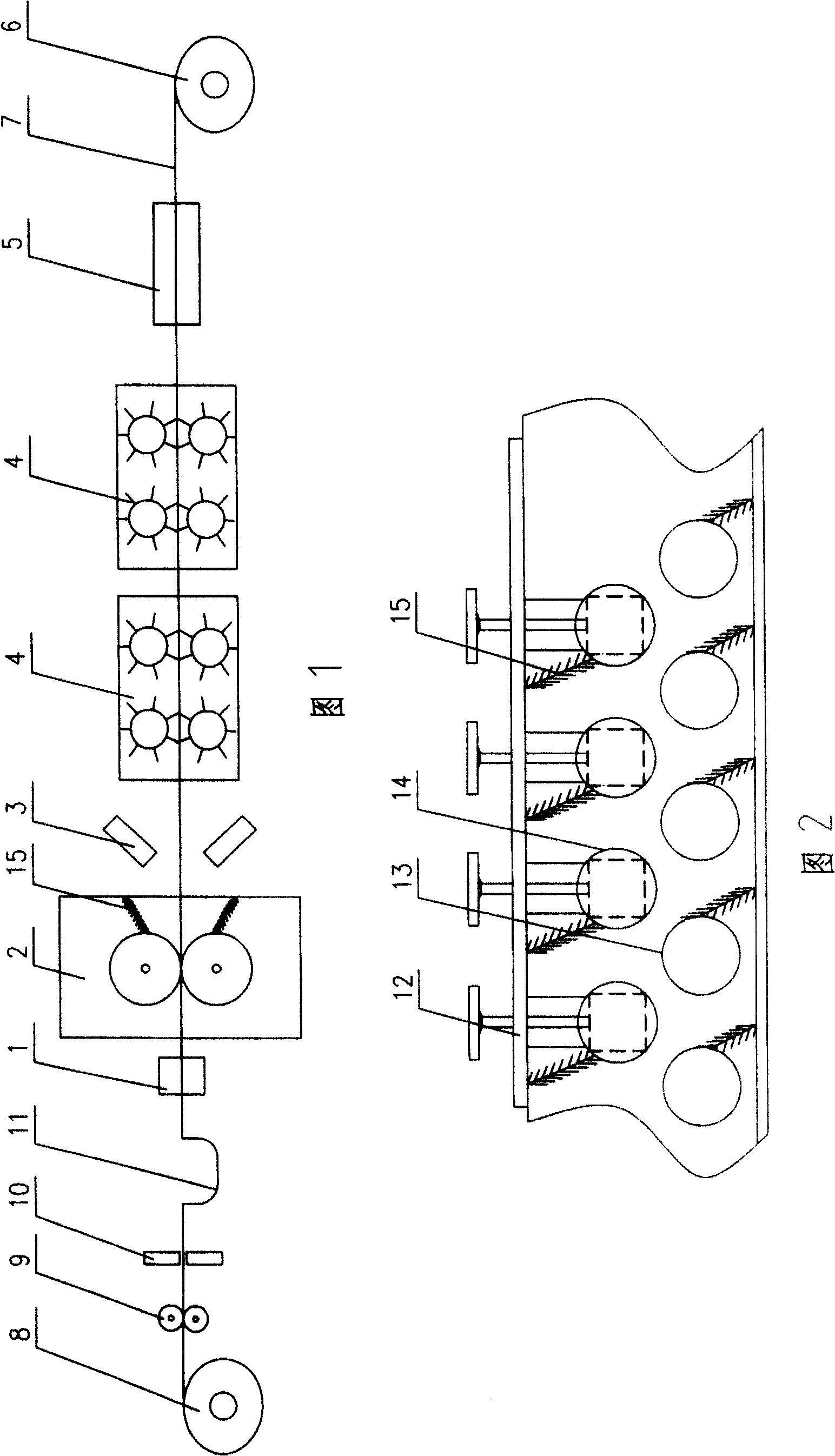

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] 1, a leveling machine mainly includes a frame 12, a leveling lower roll 13, and a leveling reduction roll 14. A roll wiper 15 is fixed on the frame 12, and the end of the roll wiper 15 and The smoothing lower roller 13 and the smoothing pressing roller 14 are in contact with each other. The roll wiper 15 can remove the iron oxide scale adhered on the surface of the roll during the rotation of the roll, avoiding the iron oxide scale being pressed into the strip steel again, thus reducing the difficulty of later removal.

[0033] It should be understood that the roll wiper 15 is not limited to be fixed on the frame 12, because in actual use it can be set at any convenient position as needed, as long as its end can be in contact with the roll to scrape it. The purpose is sufficient, so they should all fall within the protection scope of the present invention.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com