A laser rust remover for removing rust on the surface of iron metal pipes

A metal pipe, laser rust removal technology, applied in chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of difficult rust removal, large equipment volume, unfavorable environmental workers' health, etc. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

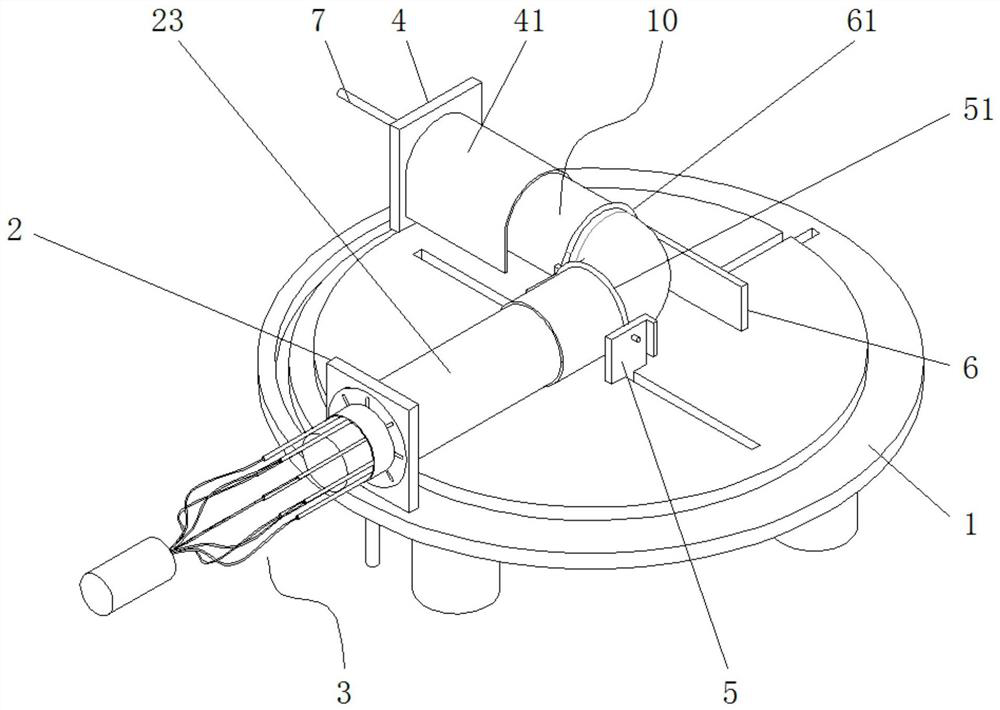

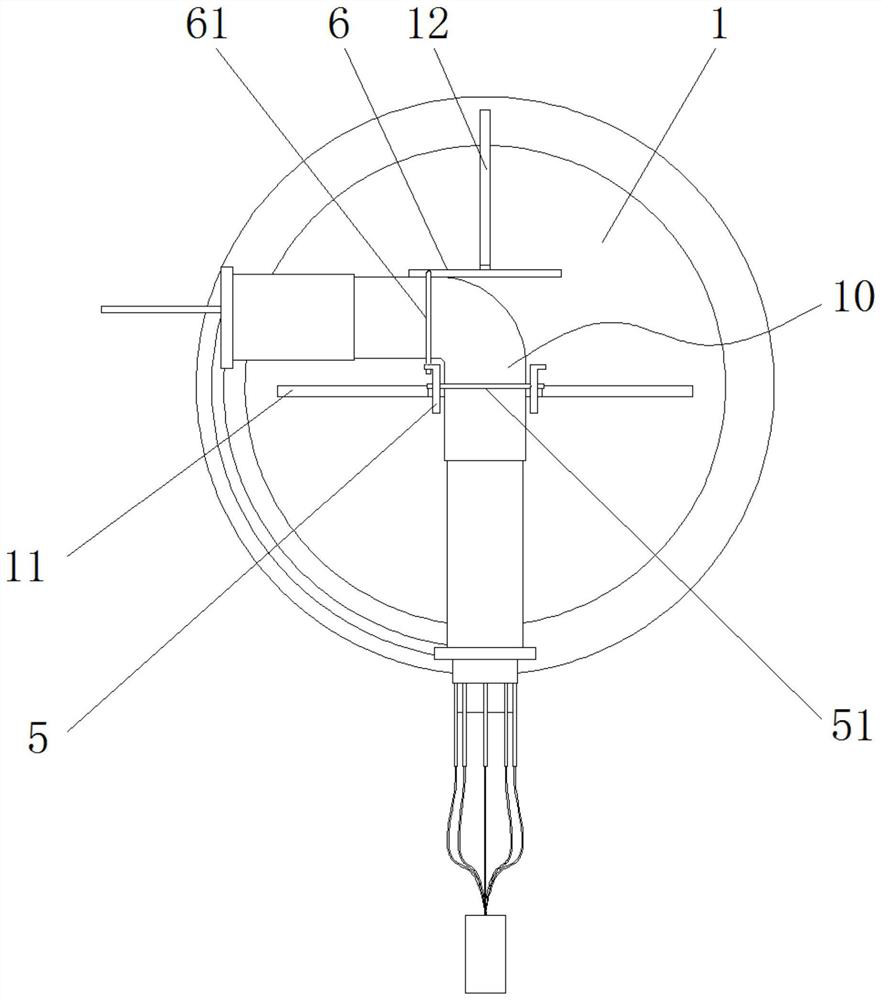

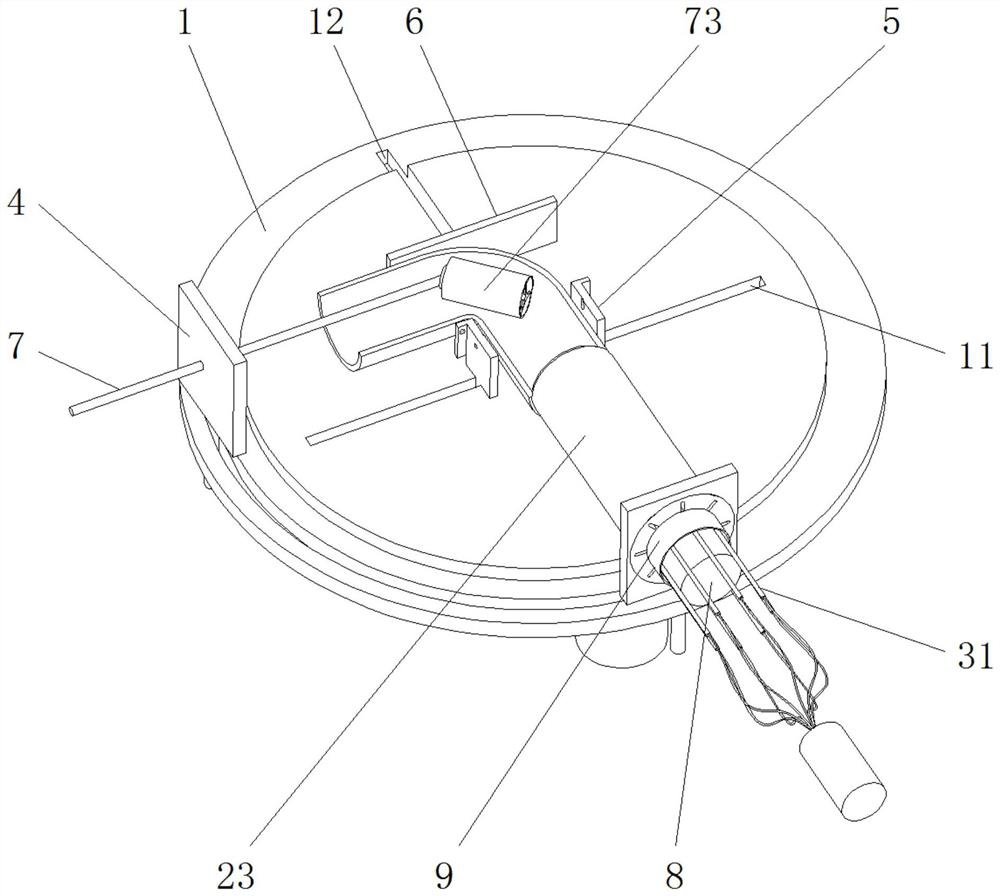

[0029] The embodiment of the present invention provides a laser rust remover for removing rust on the surface of a ferrous metal pipe, such as Figure 1-9 As shown, the inner wall of the pipe body 10 is derusted, and the pipe is an iron metal pipe. Including a workbench 1, two clamping plates 5 are slidably fitted on the top of the workbench 1, and abutting plates 6 are slidably fitted on the top of the workbench 1. as attached figure 1 As shown, the splint 5 is located on the left and right sides of the pipe body 10, and the abutting plate 6 and the splint 5 form an included angle of 90°.

[0030] A base 1 2 is fixedly installed on the front side of the top of the workbench 1 , a base 2 4 is fixedly installed on the left side of the top of the workbench 1 , and a laser transmitter 3 is connected to the base 1 2 . The laser transmitter 3 injects laser light into the pipe body 10 . The laser transmitter 3 emits a high-frequency pulsed laser to impact the inner wall of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com