High sulfide pyrite pellet reinforced roasting consolidation technology

A technology of high pyrite and high pyrite concentrate, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problem of dew point corrosion of low temperature exhaust gas, difficult removal of sulfur elements, affecting the oxidizing property, strength and consolidation speed of pellets and other problems, to achieve the effect of equipment corrosion elimination, corrosion elimination, and stable production operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

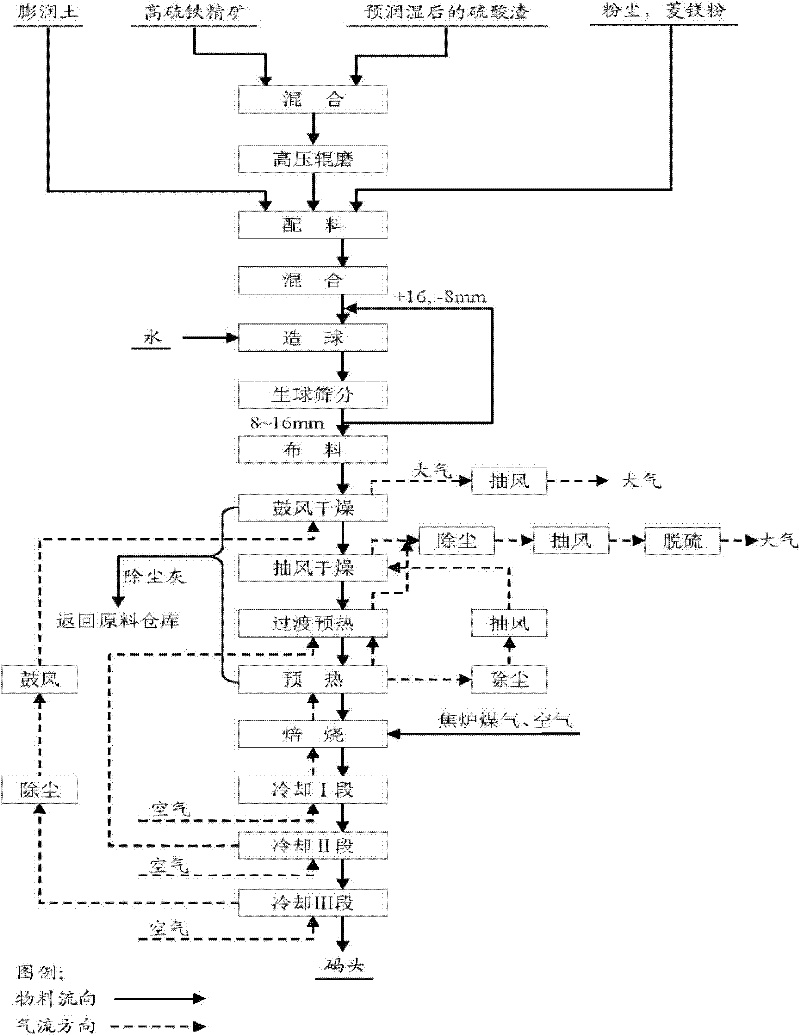

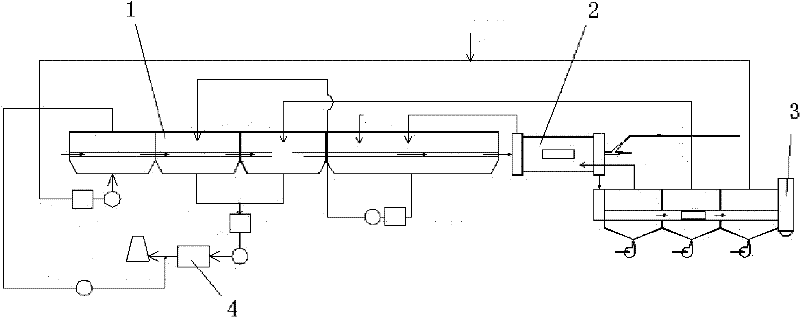

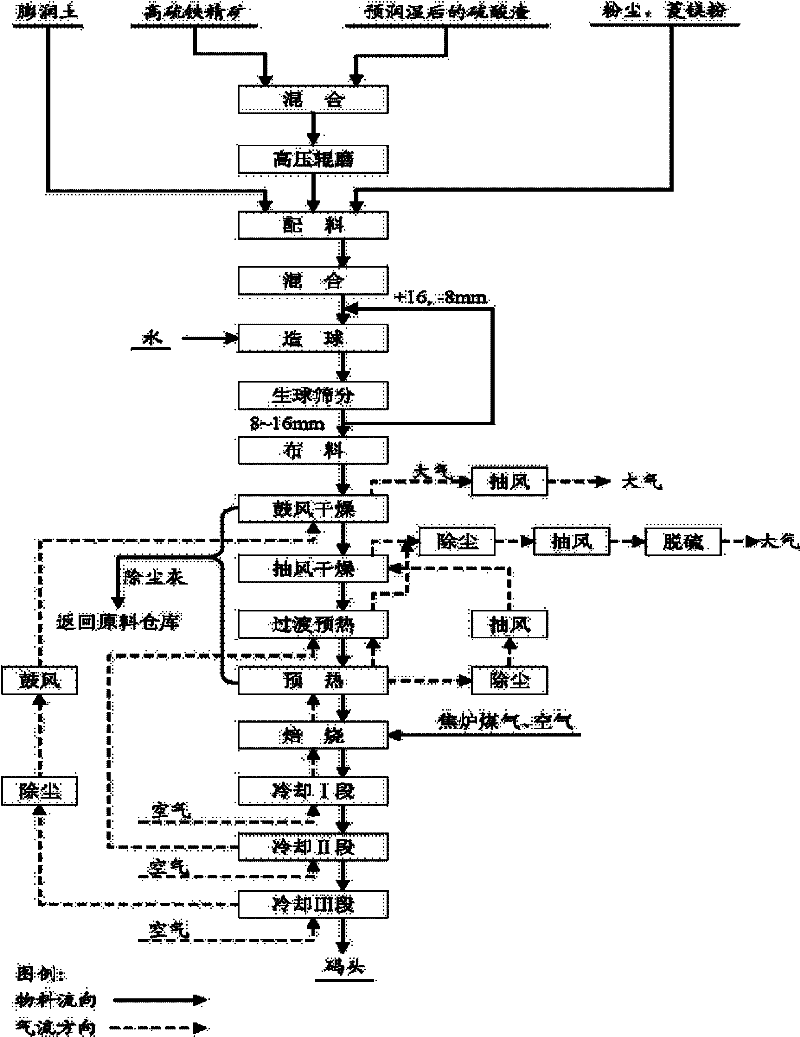

Method used

Image

Examples

Embodiment 1

[0043] Using high-sulfur iron concentrate (sulfur containing 1.5%) and sulfuric acid slag as raw materials, when the pellet mixture (40% high-sulfur iron concentrate + 60% sulfuric acid slag) contains as high as 1% sulfur, conventional pellet production Process, the strength of the finished pellet is lower than 2100N, and the finished pellet contains 0.32% sulfur. The present invention pre-wet sulfuric acid slag to water content of 14%, mix with high-sulfur iron ore (60:40), pass through high-pressure roller mill, and then mix with 1.0% organic compound bentonite and 1% magnesite, and mix it evenly. After the pellets, drying, preheating, roasting and cooling, the high-pyrite pellets are roasted, the finished pellets contain 0.018% sulfur and the compressive strength reaches 2680N, which meets or exceeds the industry standard of the first grade acid iron pellets. The system produces 1.2 million tons of iron oxide pellets annually. Corrosion of system equipment is basically elim...

Embodiment 2

[0045] Using high-sulfur iron concentrate (2% sulfur) and sulfuric acid slag as raw materials, when the pellet mixture (20% high-sulfur iron concentrate + 80% sulfuric acid slag) contains as high as 1% sulfur, conventional pellet production Process, the strength of the finished pellet is lower than 1900N, and the finished pellet contains 0.33% sulfur. The present invention pre-wet sulfuric acid slag to 15% water content, mix it with high-sulfur iron ore (80:20), then pass through high-pressure roller mill, and then mix with 1.0% organic compound bentonite and 1% magnesite, and mix it evenly. After the pellets, drying, preheating, roasting and cooling, the high-pyrite pellets are roasted, the finished pellets contain 0.015% of sulfur, and the compressive strength reaches 2590N. The system produces 1.2 million tons of iron oxide pellets annually. Corrosion of system equipment is basically eliminated, and production runs stably.

Embodiment 3

[0047] Using high-sulfur iron concentrate (sulfur 2%) and sulfuric acid slag as raw materials, the conventional pellet production process when the pellet mixture (10% high-sulfur iron concentrate + 90% sulfuric acid slag) contains 0.9% sulfur , The strength of the finished pellets is lower than 1850N, and the finished pellets contain 0.31% sulfur. The present invention pre-wet sulfuric acid slag to water content of 16%, mix it with high-sulfur iron ore (90:10), pass through high-pressure roller mill, then mix with 1.0% organic compound bentonite and 1% magnesite, and mix it evenly. After spheronizing, drying, preheating, roasting and cooling to strengthen the roasting of high pyrite pellets, the finished pellets contain 0.018% sulfur and the compressive strength reaches 2530N. The system produces 1.2 million tons of iron oxide pellets annually. Corrosion of system equipment is basically eliminated, and production runs stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com