Process for leaching vanadium out of stone coal by using oxidant and sulfuric acid

An oxidant and sulfuric acid technology, applied in the direction of improving process efficiency, can solve the problems of large amount of HCl gas, low vanadium conversion rate, large amount of NaCl added, etc., and achieve the advantages of simplifying the process, reducing energy consumption, and improving vanadium leaching rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

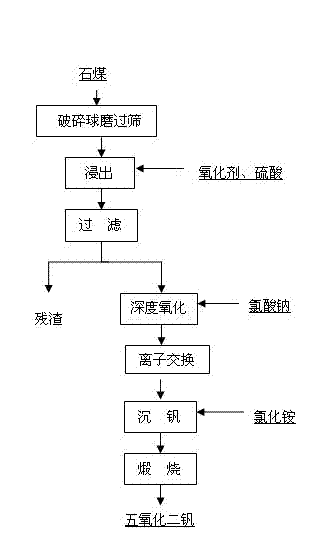

Image

Examples

Embodiment 1

[0014] (1) Crushing and ball milling and sieving: the stone coal mine is crushed and ball milled until it passes through a 100-mesh sieve. (2) Oxidant synergistic sulfuric acid leaching: control the addition of water and sulfuric acid according to the solid-liquid ratio of 1:0.5-5, put the ore powder into the acid leaching tank, and add NaNO according to the weight ratio of oxidant and stone coal 0.5-15% 2 , control the concentration of sulfuric acid to 10-35%, stir evenly, leaching at 10-100°C for 1-15 hours, and filter and separate. (3) Deep oxidation: add a certain amount of sodium chlorate solution to deeply oxidize the vanadium-containing filtrate, so that tetravalent vanadium is completely oxidized to pentavalent vanadium. (4) Ion exchange separation and enrichment: use strong basic macroporous anion exchange resin to absorb vanadium solution, and then use 10% NaOH and 5% NaCl mixed solution for desorption. (5) Precipitate vanadium: use NH to desorb the vanadium-contain...

Embodiment 2

[0016] According to the above steps of crushing ball milling and sieving, oxidant synergistic sulfuric acid leaching, deep oxidation, ion exchange separation and enrichment, vanadium precipitation, calcination and other steps in sequence, in which in the batching process, the oxidant added to the stone coal powder is KNO 2 , the weight is 5% of the ore powder, and the leaching rate of stone coal is 95%.

Embodiment 3

[0018] According to the above steps of crushing ball milling and sieving, oxidant synergistic sulfuric acid leaching, deep oxidation, ion exchange separation and enrichment, vanadium precipitation, calcination and other steps, the oxidant added to the stone coal ore powder is Ca(NO 2 ) 2 , the weight is 3% of the ore powder, and the leaching rate of stone coal is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com