Metal welded pipe joint and assemble-welding method

A welded pipe and metal technology, applied in the field of welded pipe joints and their welding, can solve the problems of affecting the corrosion resistance of pipes, large welding stress, coarse grains, etc., to achieve accurate and rapid joint joints, and eliminate the possibility of stress corrosion. , the effect of eliminating the possibility of parasitic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

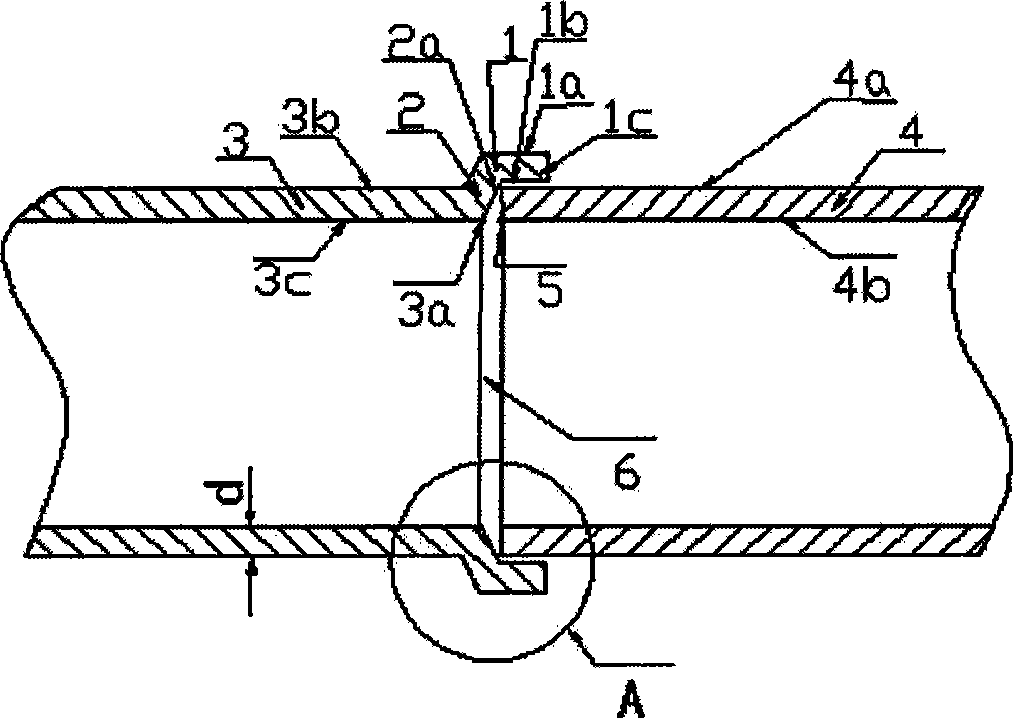

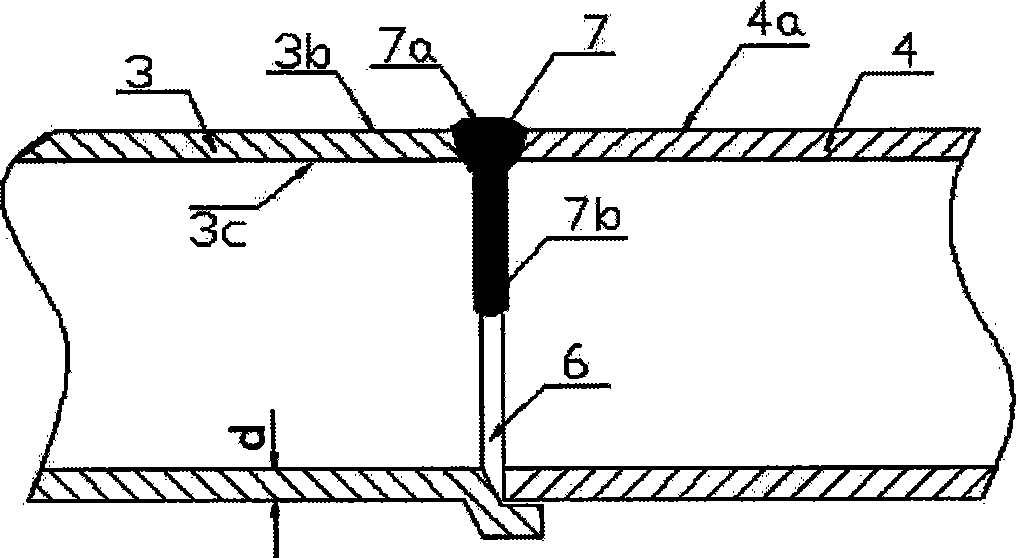

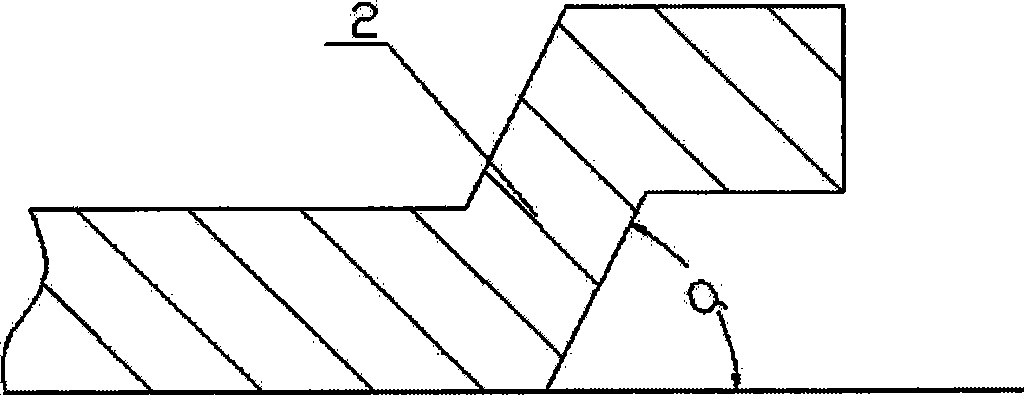

[0052]A pipe joint for hot and cold water supply, using welded pipe joint specification DN20, pipe wall thickness 0.6mm, joint thickness 0.6mm, made of SUS316L or SUS304 austenitic stainless steel, also suitable for SUS444 ferritic stainless steel and other metal materials , The characteristics are: metal thin-walled pipes and pipe fittings are socket lapped and butt welded. The assembly and welding method has the following steps in sequence: 1) pretreatment and preconfiguration; 2) inserting an internal gas protection device; 3) fitting the joints of socket lap joints in place; 4) temporarily fixing; 5) butt welding forming. It is formed by inserting the pipe or fitting into the socket of the joint body made of thin-walled stainless steel, and then welding the joint body and the pipe or fitting using the butt filler welding process.

[0053] Wherein, step 2) inserting the internal air protection device is to adopt the pre-insertion method, and before the insertion, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com