Composite Discharge Electrode

a discharge electrode and composite technology, applied in the direction of discharge tube/lamp details, discharge tube main electrodes, discharge tubes/lamp details, etc., can solve the problems of affecting the charging efficiency of discharge electrodes. , to achieve the effect of improving the charging characteristic and collection efficiency, reducing the cost and weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

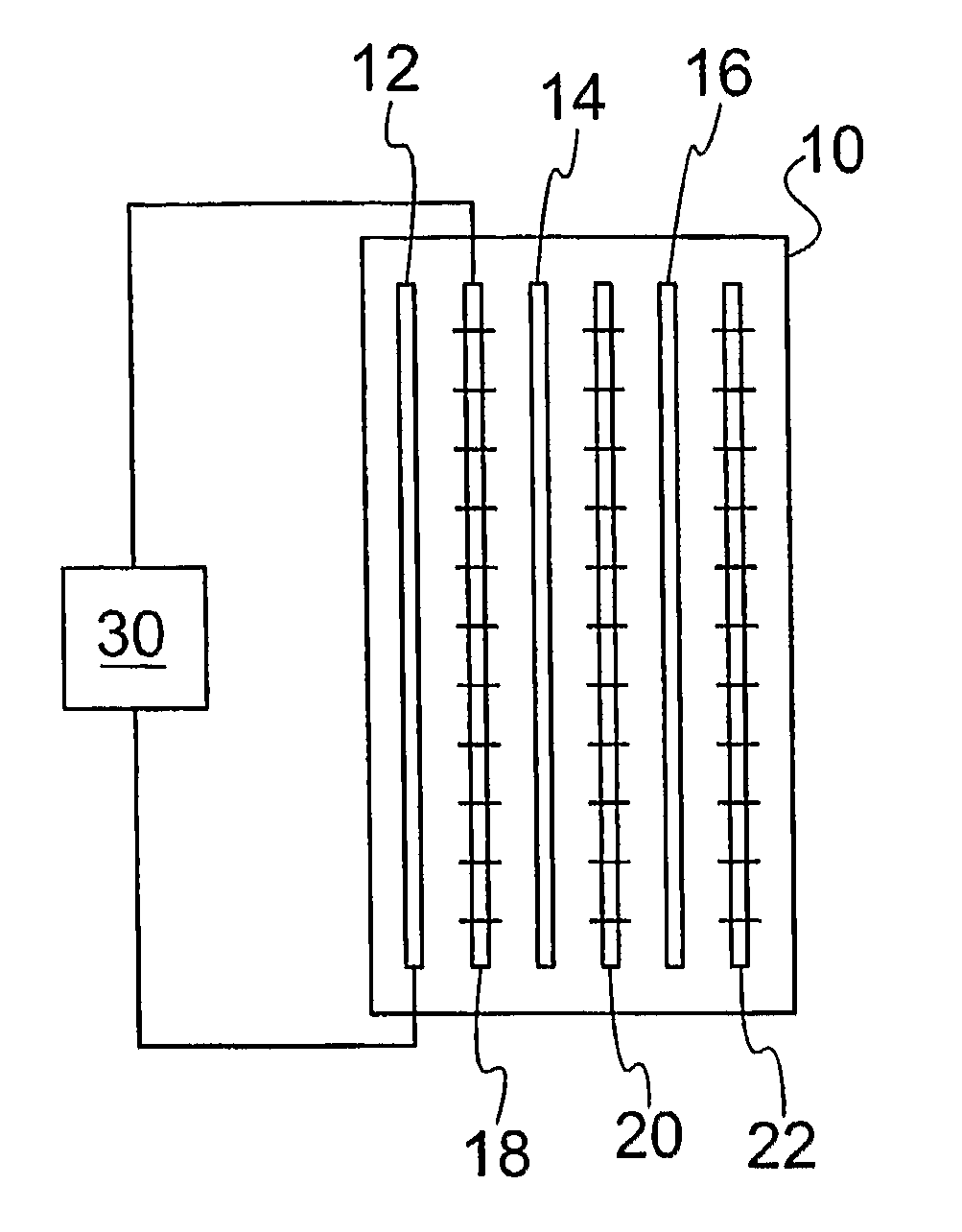

[0029]In FIG. 1 an ESP is shown schematically having a housing 10, which can be a flue gas chimney, a plurality of planar collection electrode plates 12, 14 and 16, and a plurality of discharge electrodes 20, 22 and 24. The discharge electrodes and collection plates are supported by a frame (not shown), which can be integral with the housing 10, and are electrically connected to a power supply 30. Gases, such as flue gases containing flyash particles, flow through the housing 10 in a flow path across the plates 12-16 and the discharge electrodes 20-24, which function according to the principles discussed herein, and with much improved performance over the prior art due to the improvements to the discharge electrodes 20-24.

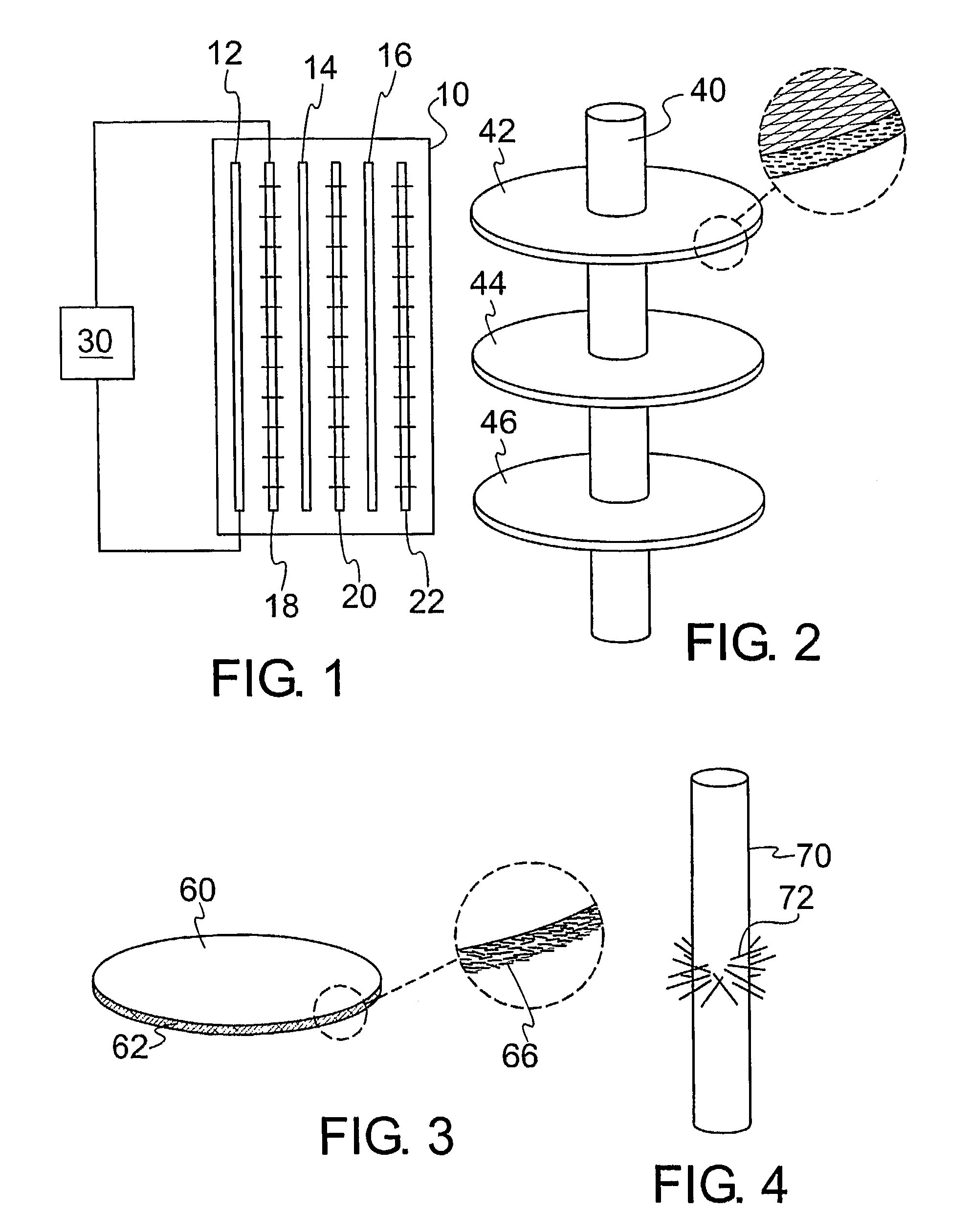

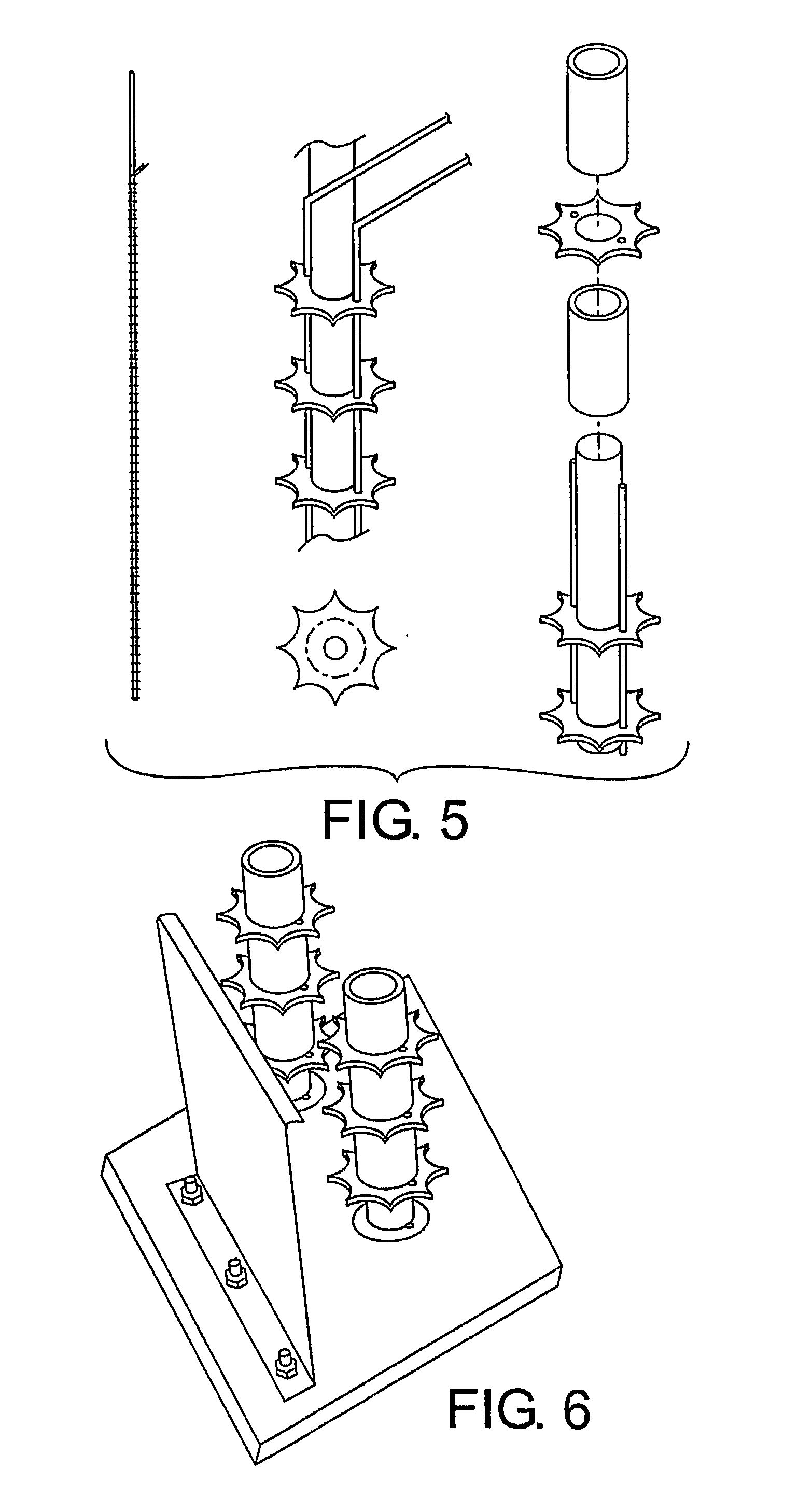

[0030]Each discharge electrode system, an example of which is shown schematically in FIG. 2, has a supporting rod 40 that supports a plurality of fiber composite discharge electrode plates, such as the circular disks 42, 44 and 46, spaced along the length of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com