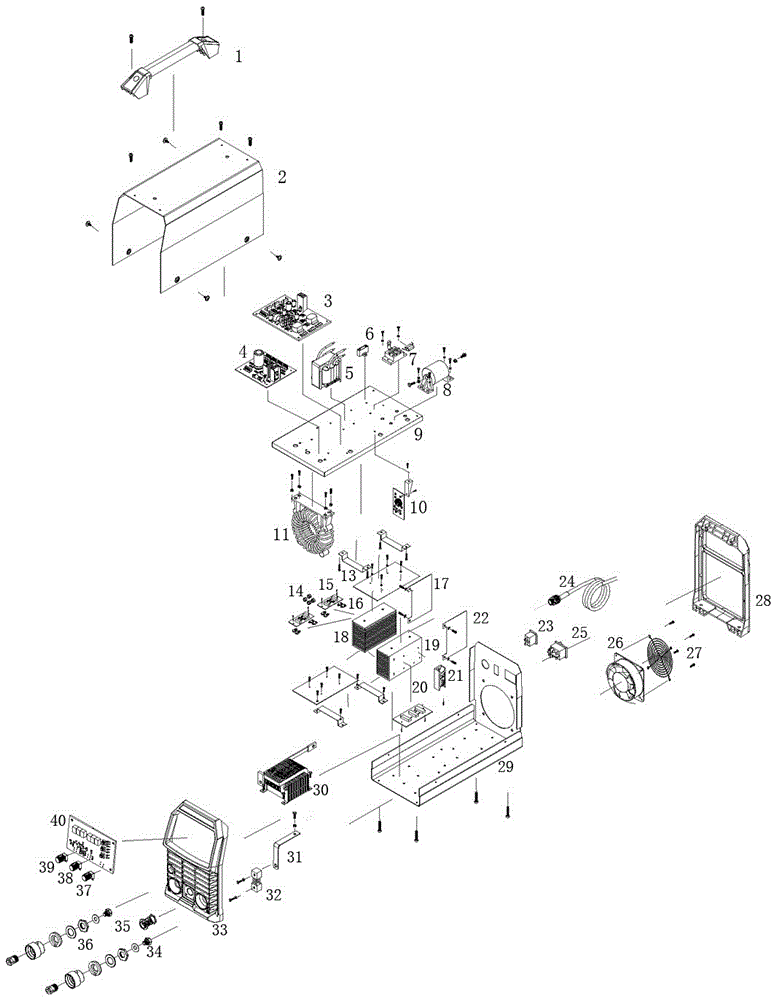

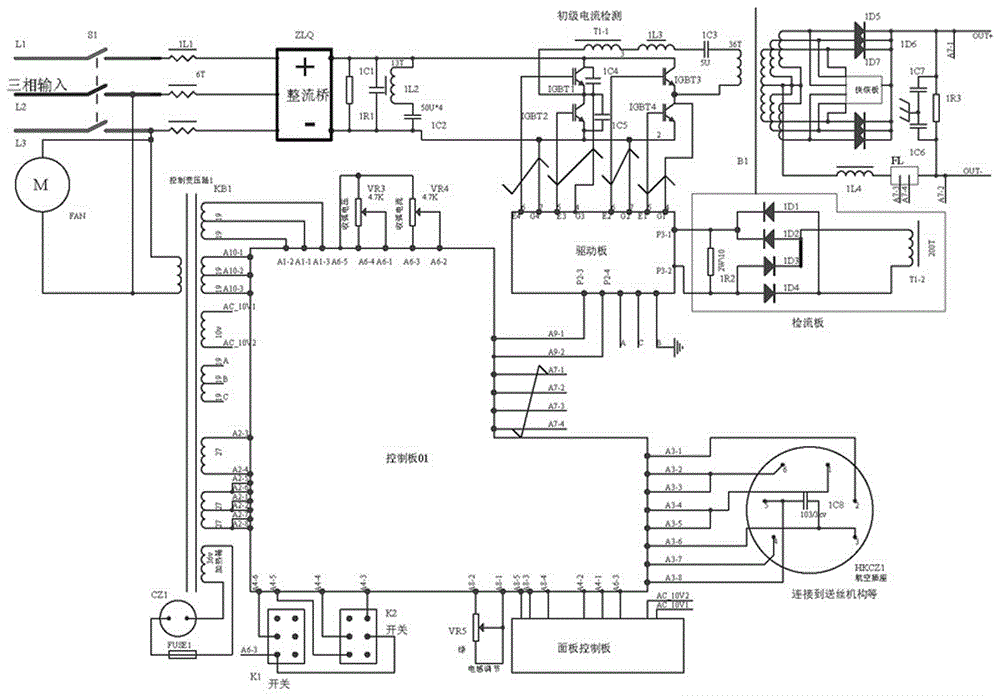

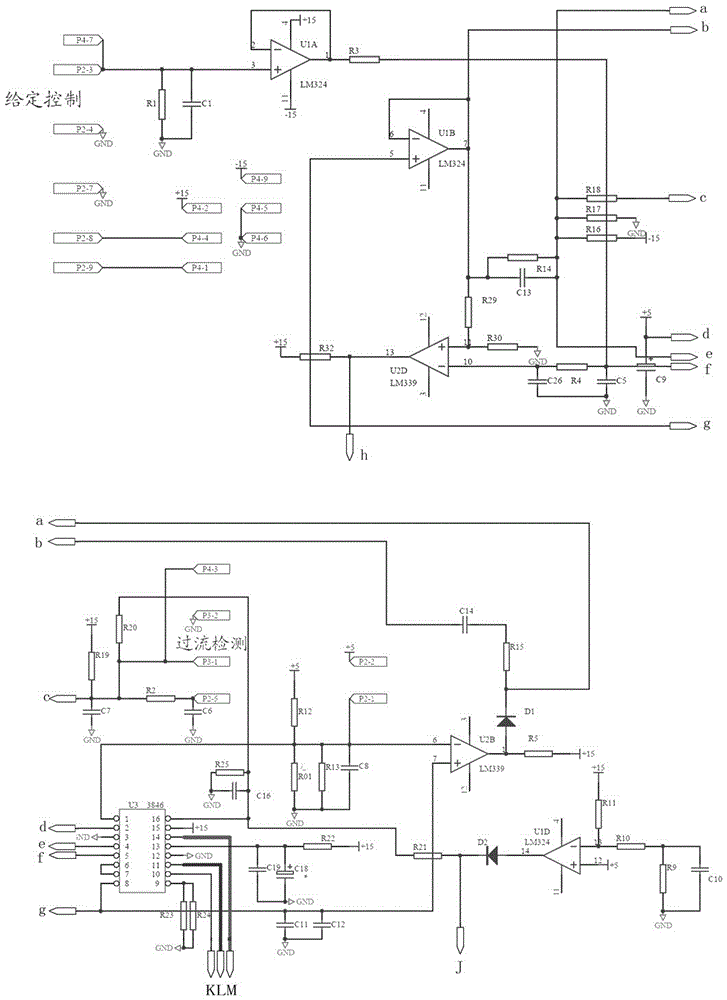

Structure of IGBT inverter welding machine with two welding functional modules

A technology of inverter welding machines and functional modules, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low reliability, low sales price, high cost, etc., and achieve high reliability, high efficiency and low cost production, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The wire feeding mechanism, the welding torch and the shielding gas source part involved in the present invention mainly include the wire feeding mechanism, the gas shielded welding torch and the shielding gas cylinder. These parts are standard auxiliary parts in addition to the welder of the present invention. It is also available in the market. This patent specification only illustrates the relationship between these parts and the present invention. During gas shielded welding, the plug part of the control line on the wire feeding mechanism is connected to the aviation socket on the front panel of the welding machine (35, the number represents the attached figure 1 The part codes in, the same below) make corresponding connections. The welding torch is matched and connected with the welding torch seat of the wire feeding mechanism. The welding wire is mounted on the wire spool of the wire feed mechanism. The welding wire can pass through the wire feeding wheel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com