A structure of igbt inverter welding machine with two welding functions

An inverter welding machine and functional technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of high sales price and unfavorable product competition, achieve large machine size, simplify production process, control The effect of fewer connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

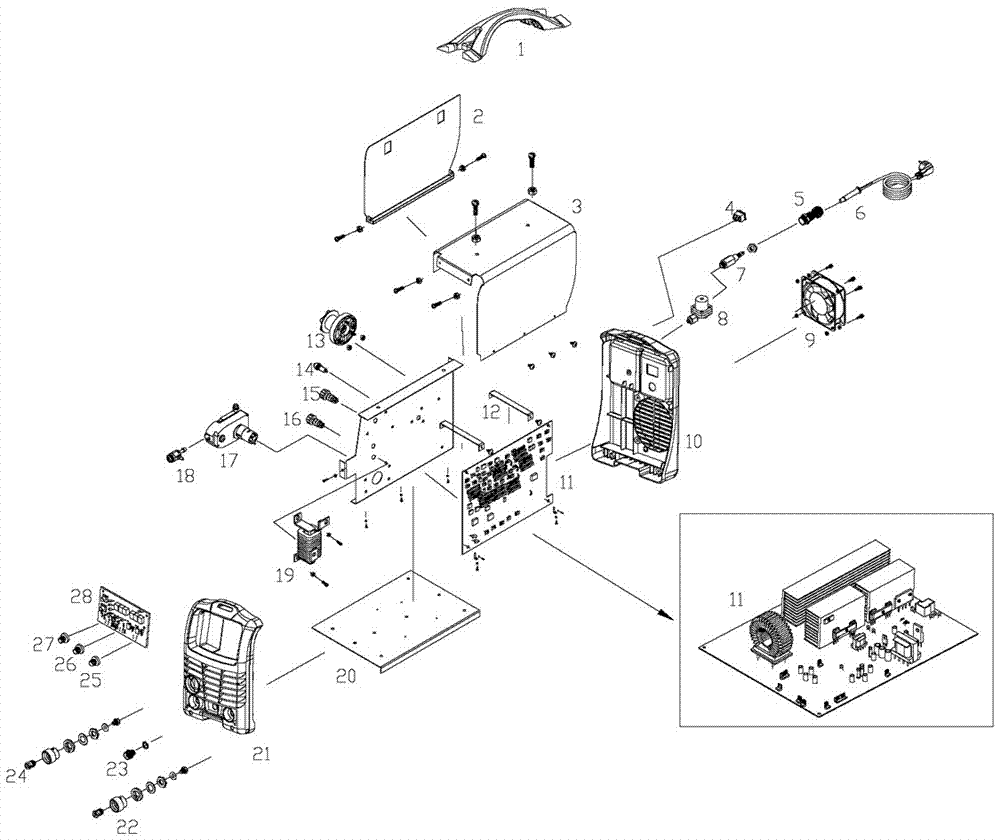

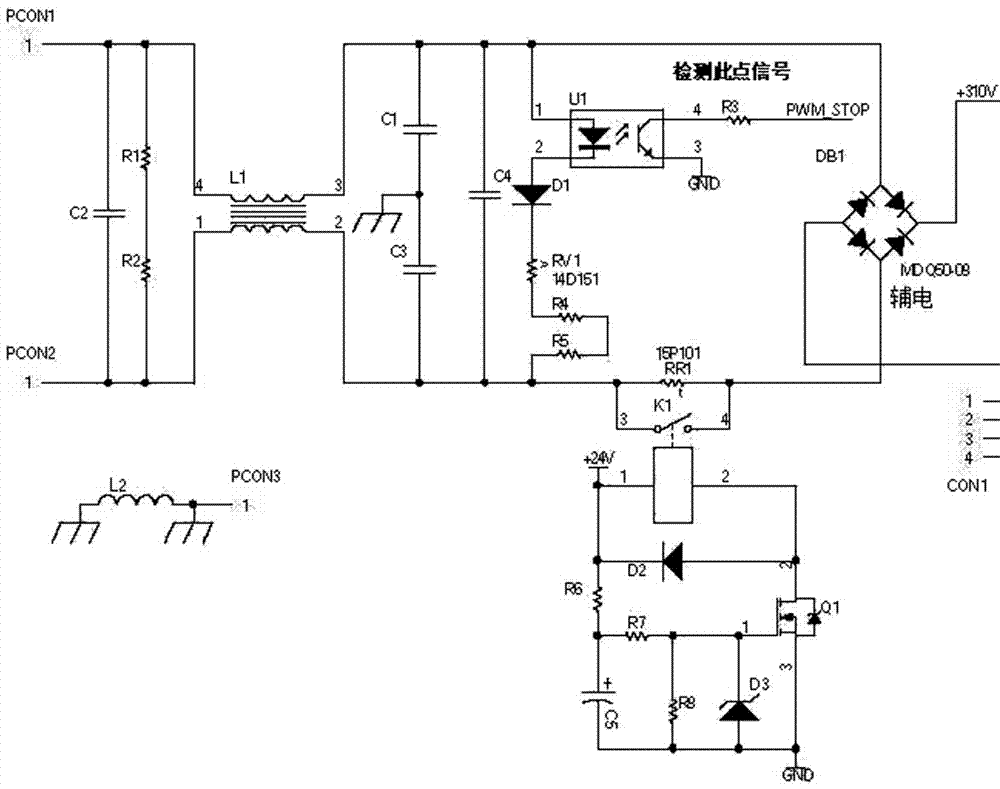

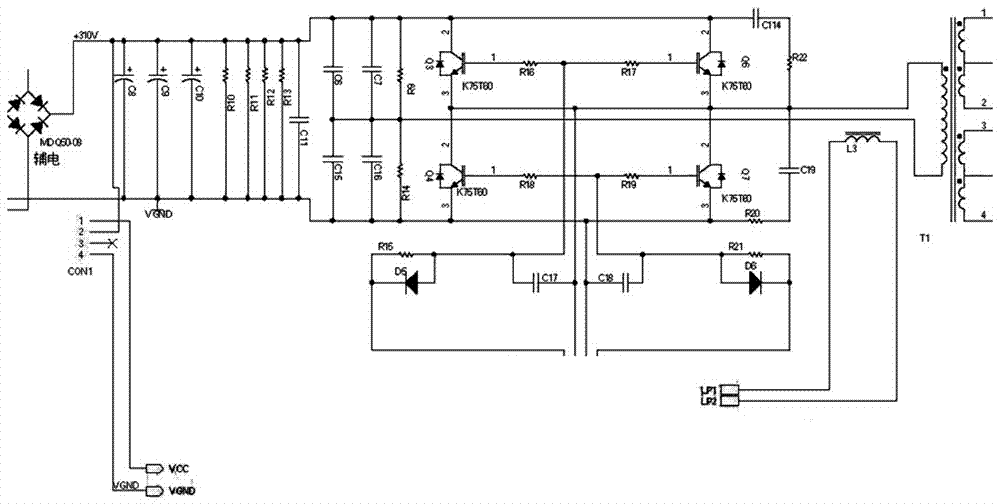

[0028] Such as Figure 1-11 As shown, the main components of the welding machine include: 1) Wire feeding part. It mainly includes: a welding wire spool 13 for gas shielded welding, a wire feeding mechanism 17, a European style gas shielded welding torch interface copper head 18 and a wire feeding control circuit part on the single board. The wire feeding mechanism 17 and the wire feeding reel shaft 13 are installed on the inner middle partition. The wire feeding mechanism 17 is close to the front panel 21 of the welding machine. The wire feeding mechanism 17 is connected with the European-style gas shielded welding torch interface copper head 18 installed on the front panel 21 accordingly. During gas shielded welding, the gas shielded welding torch is connected with the copper head 18 of the European style gas shielded welding torch interface. The welding wire is mounted on the wire spool 13. After the welding wire is installed, it can be sent into the wire feeding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com