Method of preparing ultra low dielectric constant polyimide membrane by polyamide ester precursor phase transformation

An ultra-low dielectric constant, polyimide film technology, applied in the field of preparation of polymer dielectric materials, can solve the problems of high cost, difficult to scale, complex preparation method, etc., and achieves low cost, simple process and equipment , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

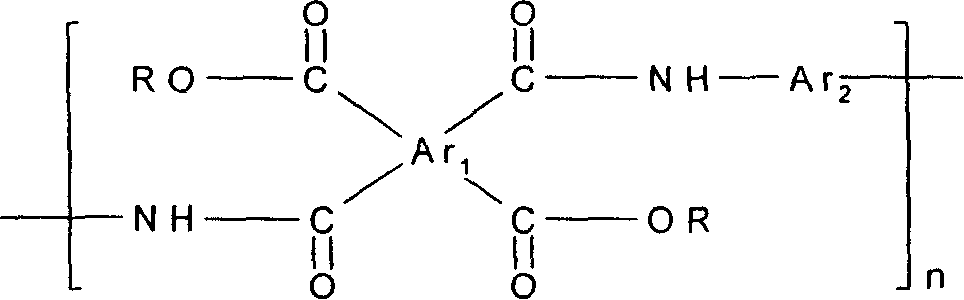

Method used

Image

Examples

Embodiment 1

[0056] Example 1: The various implementation conditions and the structure and performance of the obtained ultra-low dielectric constant polyimide film are shown in Table 1.

[0057]

Embodiment 2

[0058] Example 2: The various implementation conditions and the structure and properties of the obtained ultra-low dielectric constant polyimide film are shown in Table 2.

[0059]

Embodiment 3

[0060] Example 3: The various implementation conditions and the structure and properties of the obtained ultra-low dielectric constant polyimide film are shown in Table 3.

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com