Preparation method of instant gracilaria agar with low freezing point

A low freezing point, instant technology, applied in the field of seaweed product processing, can solve problems such as the application limitation of agar, and achieve the effect of broadening the application field of products, improving yield, improving agar preparation technology and high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

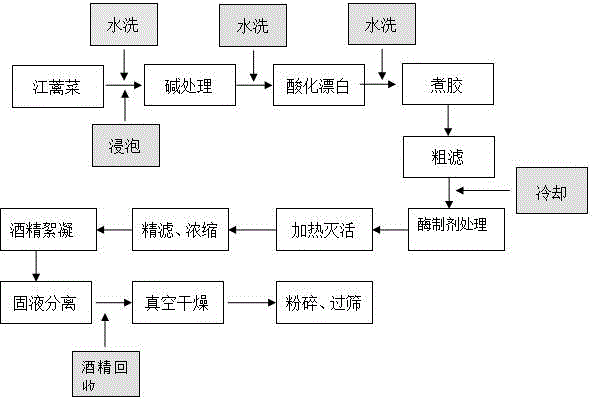

[0028] A method for preparing instant gracilaria agar with low freezing point, using gracilaria as raw material, removing salt and sand through drum sieve, alkali treatment, acidification and bleaching, boiling the gelatin, coarsely filtering the gelatinous solution, cooling down, treating with compound enzyme preparation, and heating to extinguish Extraction, fine filtration, vacuum concentration, alcohol flocculation, solid-liquid separation, vacuum drying, crushing, and sieving to obtain instant Gracilaria agar with low freezing point.

[0029] A preparation method for low freezing point instant Gracilaria agar, comprising the following steps:

[0030] (1) Preparation of agar coarse filtration solution: Weigh 100g of Gracilaria gracilaria, remove salt and sand through a drum sieve, add 2000g of 8wt% NaOH solution, soak at 85°C for 4 hours; then rinse with water until the pH is 7.5 , drain the water and add 2000g concentration of 0.05wt% HCl and 0.10wt% NaClO 2 The mixed so...

Embodiment 2

[0037] A method for preparing instant gracilaria agar with low freezing point, using gracilaria as raw material, removing salt and sand through drum sieve, alkali treatment, acidification and bleaching, boiling the gelatin, coarsely filtering the gelatinous solution, cooling down, treating with compound enzyme preparation, and heating to extinguish Extraction, fine filtration, vacuum concentration, alcohol flocculation, solid-liquid separation, vacuum drying, crushing, and sieving to obtain instant Gracilaria agar with low freezing point.

[0038] A preparation method for low freezing point instant Gracilaria agar, comprising the following steps:

[0039] (1) Preparation of agar coarse filtration solution: Weigh 100g of Gracilaria gracilaria, remove salt and sand through a drum sieve, add 3000g of 8wt% NaOH solution, soak at 85°C for 4h; then rinse with water until the pH is 8.0 , drain the water and add 2500g concentration of 0.05wt% HCl and 0.10wt% NaClO 2 The mixed solutio...

Embodiment 3

[0046] A method for preparing instant gracilaria agar with low freezing point, using gracilaria as raw material, removing salt and sand through drum sieve, alkali treatment, acidification and bleaching, boiling the gelatin, coarsely filtering the gelatinous solution, cooling down, treating with compound enzyme preparation, and heating to extinguish Extraction, fine filtration, vacuum concentration, alcohol flocculation, solid-liquid separation, vacuum drying, crushing, and sieving to obtain instant Gracilaria agar with low freezing point.

[0047] A preparation method for low freezing point instant Gracilaria agar, comprising the following steps:

[0048] (1) Preparation of agar coarse filtration solution: Weigh 1000kg Gracilaria gracilaria, remove salt and sand through a drum sieve, add 25M3 NaOH solution with a concentration of 8wt%, soak at 82°C for 4 hours; then rinse with water until the pH is 7.5 , drain the water and add 25M3 concentration of 0.05wt% HCl and 0.10wt% NaC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com