IGBT inverter multi-function welding machine with liquid crystal display and multi-input voice prompt functions

A liquid crystal display and voice prompt technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of limited application range, weak market competitiveness, inability to use other power supply voltages or welding functions, etc., to meet the requirements of high efficiency and Low-cost production, strong market competitiveness and adaptability, and the effect of enhancing technological added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

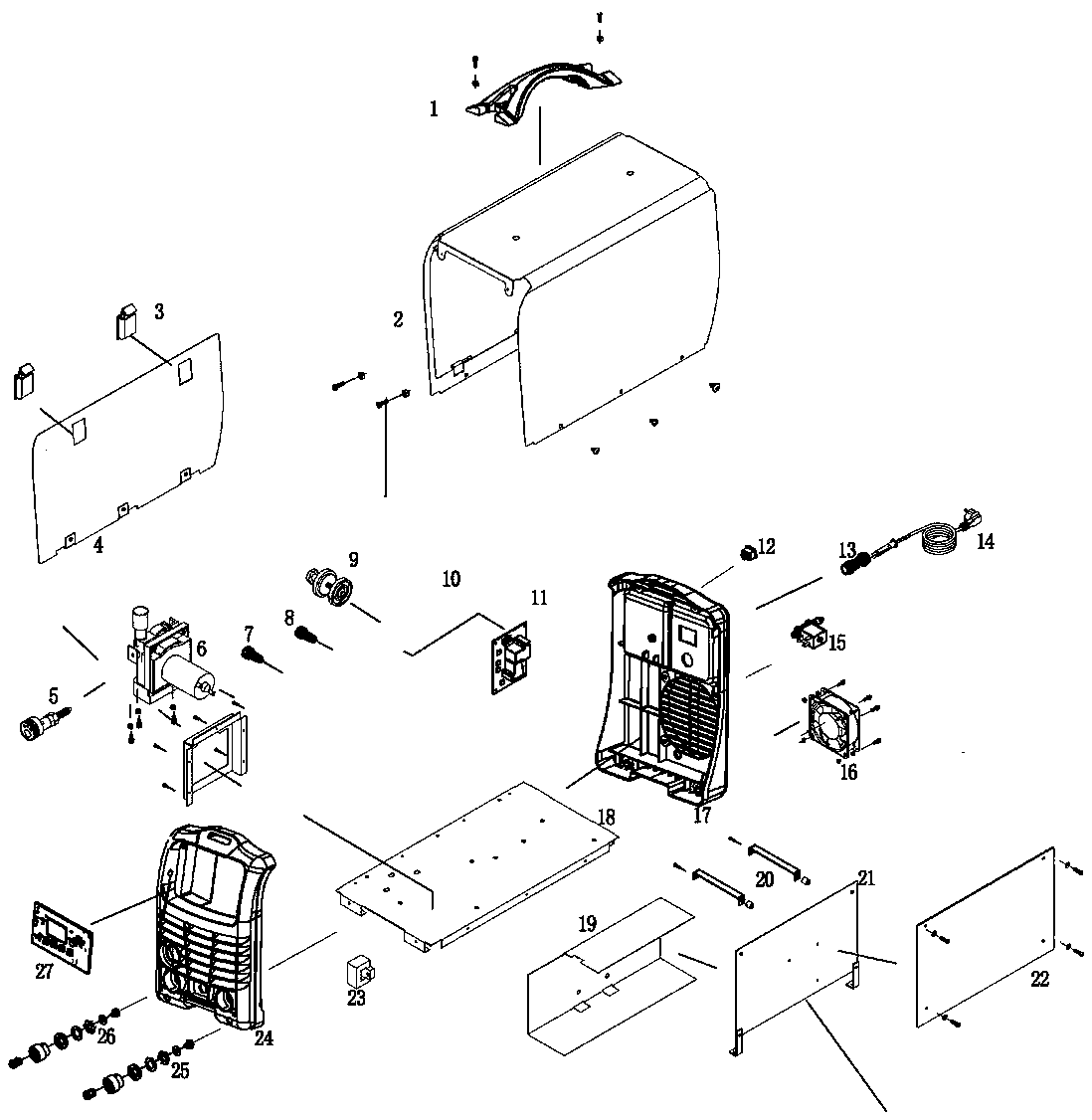

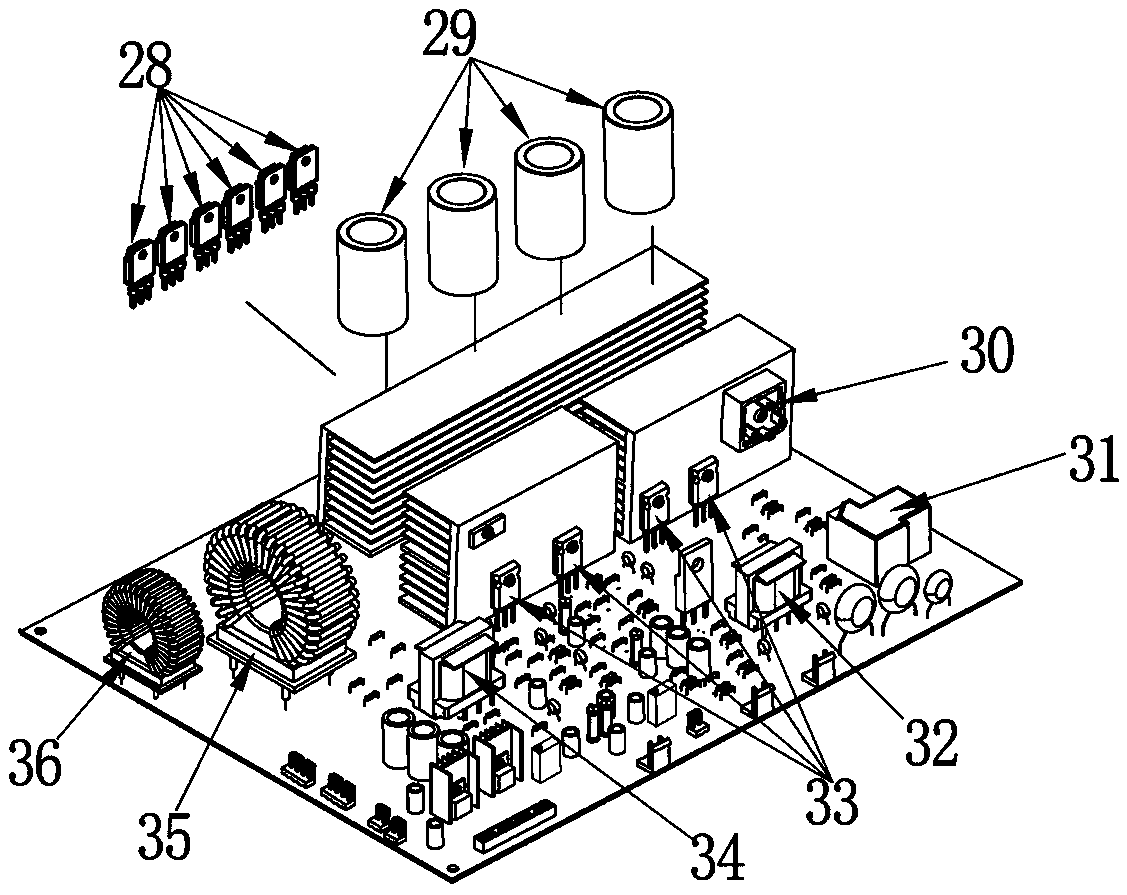

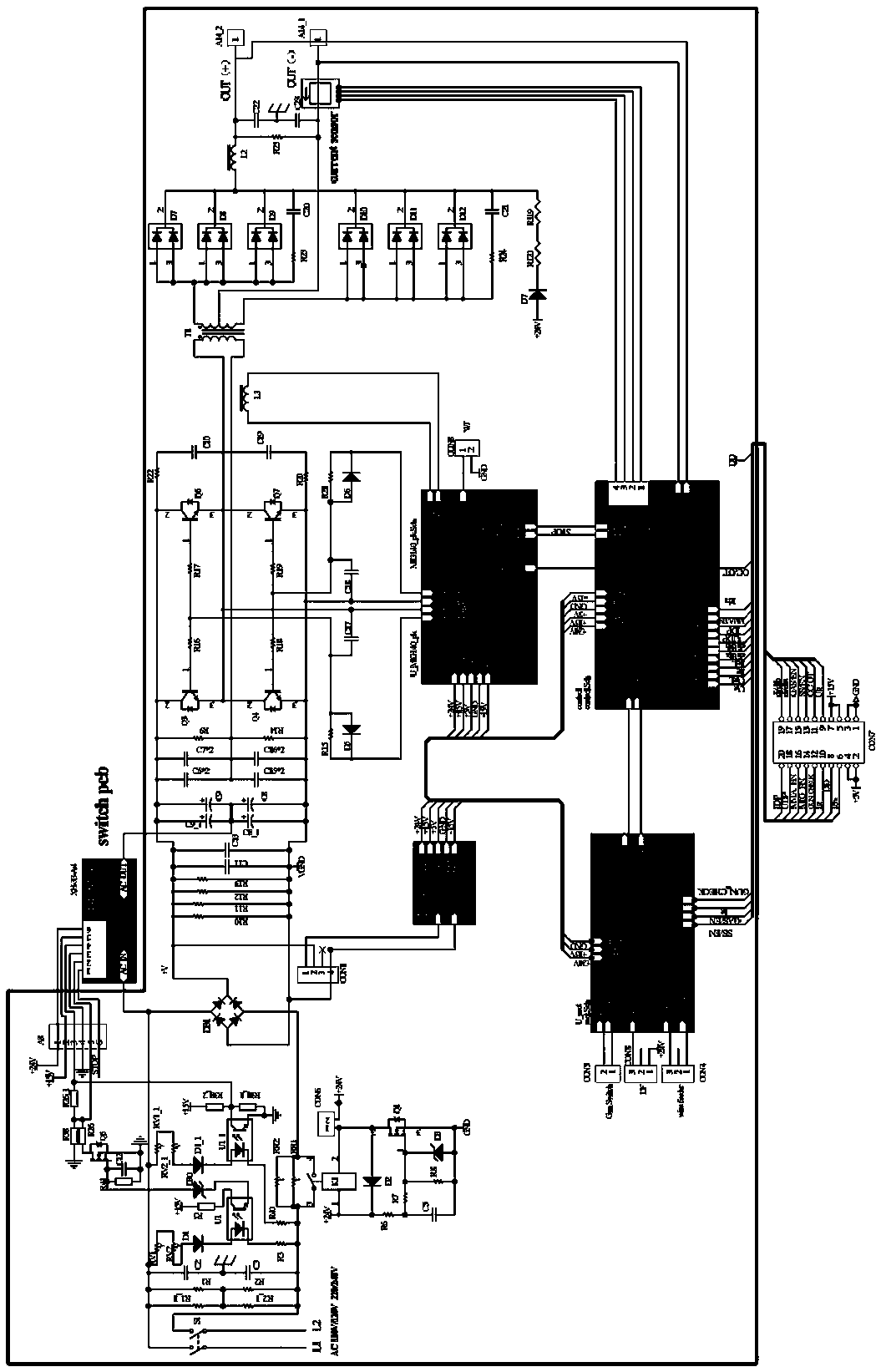

[0029] as attached figure 1 , attached figure 2 shown. attached figure 1 It is a structural design diagram of a MIG / MAG gas-shielded IGBT inverter welding machine with manual arc welding and argon arc welding functions made by the present invention. attached figure 2 It is a structural schematic diagram of the main control board 21 in the structural schematic diagram of the example welding machine. The main components of the welding machine include:

[0030] 1) Wire feeding part. It mainly includes: a wire reel shaft 9 for gas shielded welding, a wire feeding mechanism 6, a European style gas shielded welding torch interface copper head 5 and a wire feeding control circuit part on the main control board. The wire feeding mechanism 6 and the wire feeding disc shaft 9 are installed on the inner middle partition 10 . The wire feeding mechanism 6 is close to the front panel 24 of the welding machine. The wire feeding mechanism 6 is connected with the European-style gas s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com