Multi-machine parallel control topological structure based on high-voltage inverters

A technology of high-voltage frequency converter and topology structure, which is applied in the direction of AC motor control, control system, high-efficiency power electronic conversion, etc., to achieve the effect of saving design cost, responding in a timely manner, and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

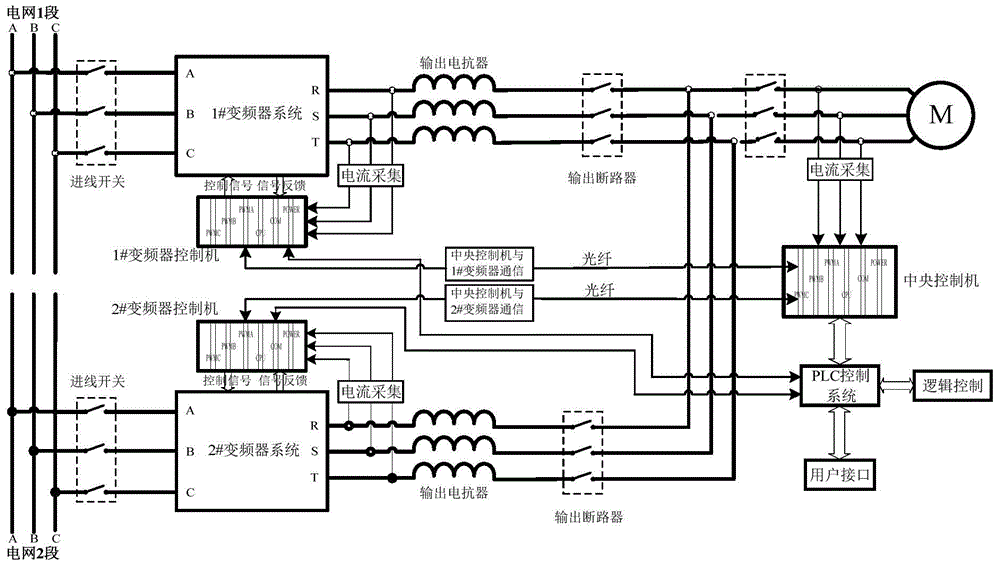

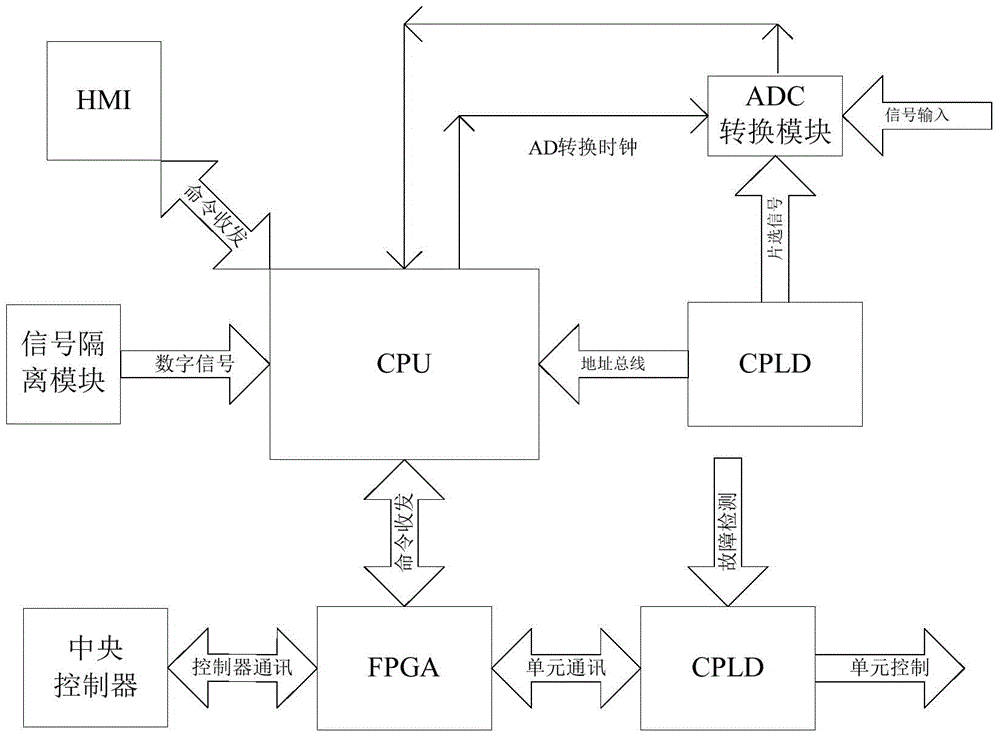

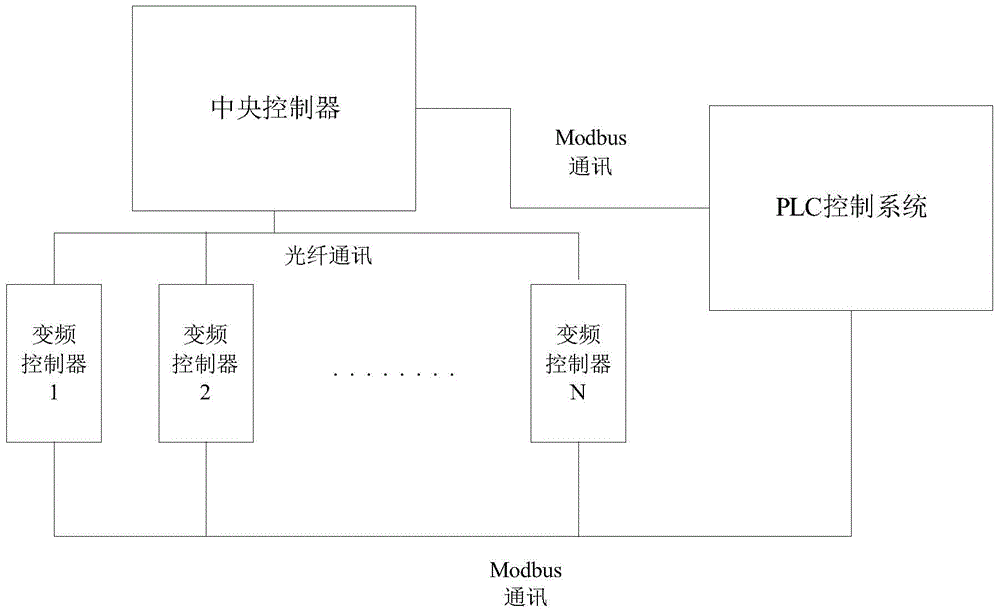

[0024] Such as figure 1 As shown, a multi-machine parallel control topology based on high-voltage inverters, including two cascaded high-voltage inverters, a central controller, a set of PLC control system, 1# inverter on the first section of the grid and the The 2# inverter on the 2nd section is connected in parallel with the reactor that suppresses the base current of the ring wave in series at the output end. Each high-voltage inverter control system communicates with the central controller through 10M optical fiber, and communicates with the PLC control system. The control system of a single high-voltage inverter accurately collects the state of each inverter and transmits it to the central controller. The central controller collects the state of the parallel system, coordinates the parallel circuit and each actuator, and realizes the current equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com