DC power supply unit control detection system and method

A DC power supply and unit control technology, applied in control/regulation systems, electrical components, DC power input conversion to DC power output, etc., can solve problems such as busbar fluctuations, unfavorable power grids, and inability to quickly track, save costs, avoid Effects of loss and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

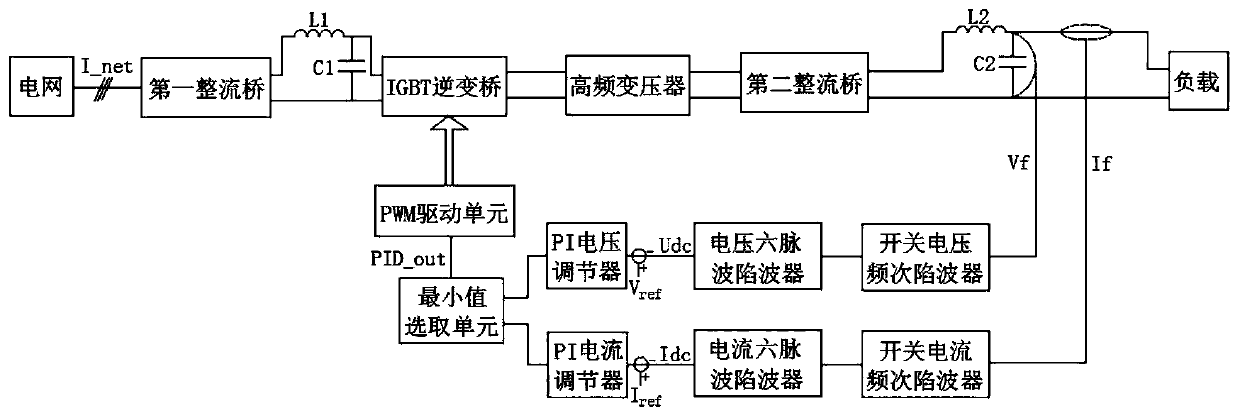

[0033] The present invention is realized through the following technical solutions, as figure 1 As shown, a DC power supply unit control and detection system is connected to the DC power supply unit, the input end of the DC power supply unit is connected to the power grid, and the bus output end of the DC power supply unit is connected to a load. The DC power supply unit includes sequentially connected The first rectifier bridge, the IGBT inverter bridge, the high-frequency transformer, and the second rectifier bridge, the input end of the first rectifier bridge is connected to the grid, the output end of the first rectifier bridge is connected to the input end of the IGBT inverter bridge, and the IGBT The output end of the inverter bridge is connected to the input end of the high-frequency transformer, the output end of the high-frequency transformer is connected to the input end of the second rectifier bridge, and the output end of the second rectifier bridge is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com