Multifunctional full-numeralization contravariant welding machine

A fully digital, inverter welding machine technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of single welding mode of inverter welding machine, etc., and achieve the effect of suppressing arc length interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

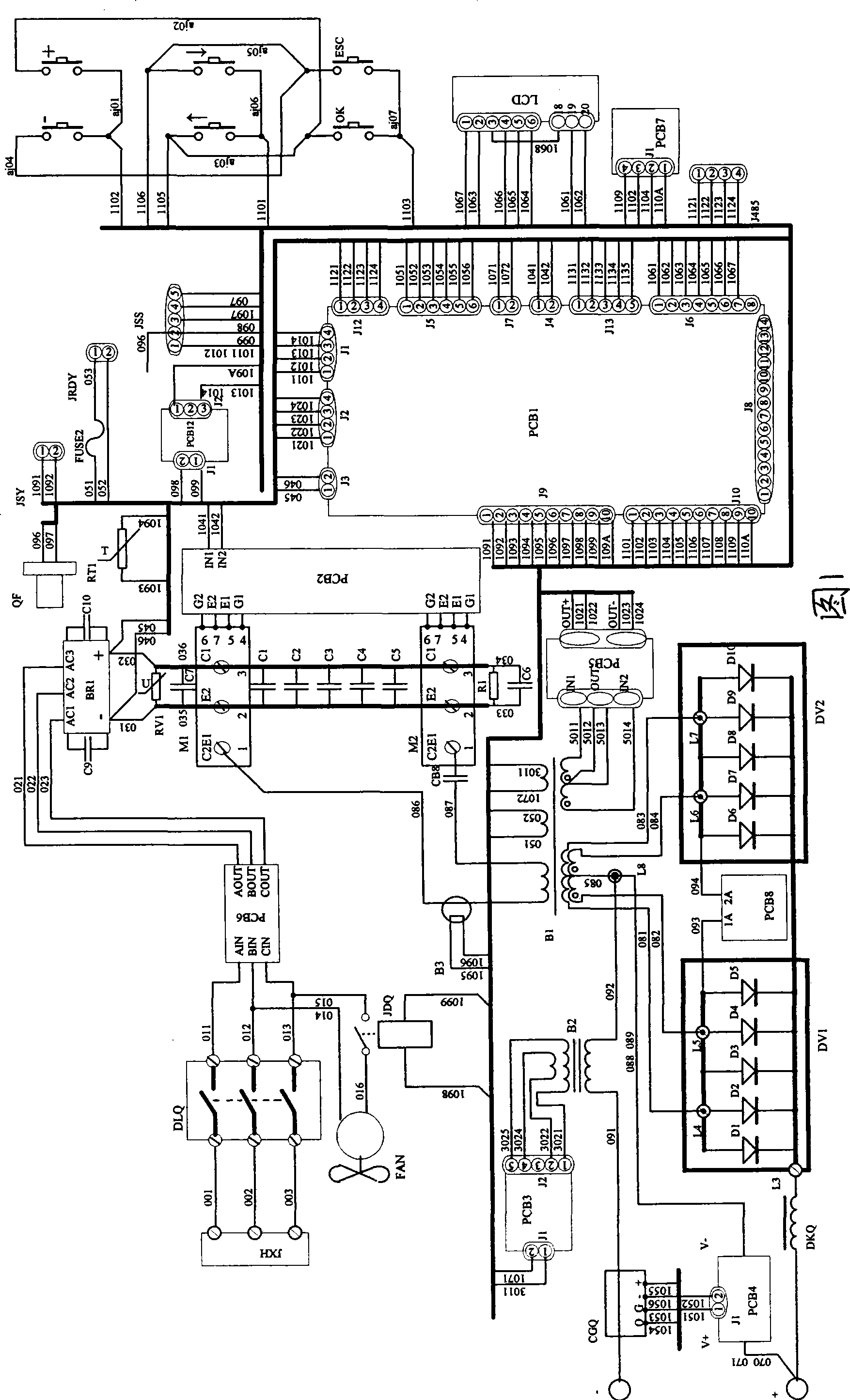

[0031] Multifunctional fully digital inverter welding machine, its working circuit includes: the main circuit containing the IGBT inverter rectifier bridge composed of two dual IGBT power tube integrated blocks M1 and M2, and the control to control the conduction width of the IGBT inverter rectifier bridge Circuit, the input end of the IGBT inverter rectifier bridge is connected to the three-phase power supply via the three-phase bridge rectifier circuit BR1, the anti-interference protection circuit PCB6, and the circuit breaker DUQ. The output end of the IGBT inverter rectifier bridge is connected in parallel with the main transformer B1. A full-bridge rectifier circuit DV is connected in series with the secondary output terminal of the transformer B1;

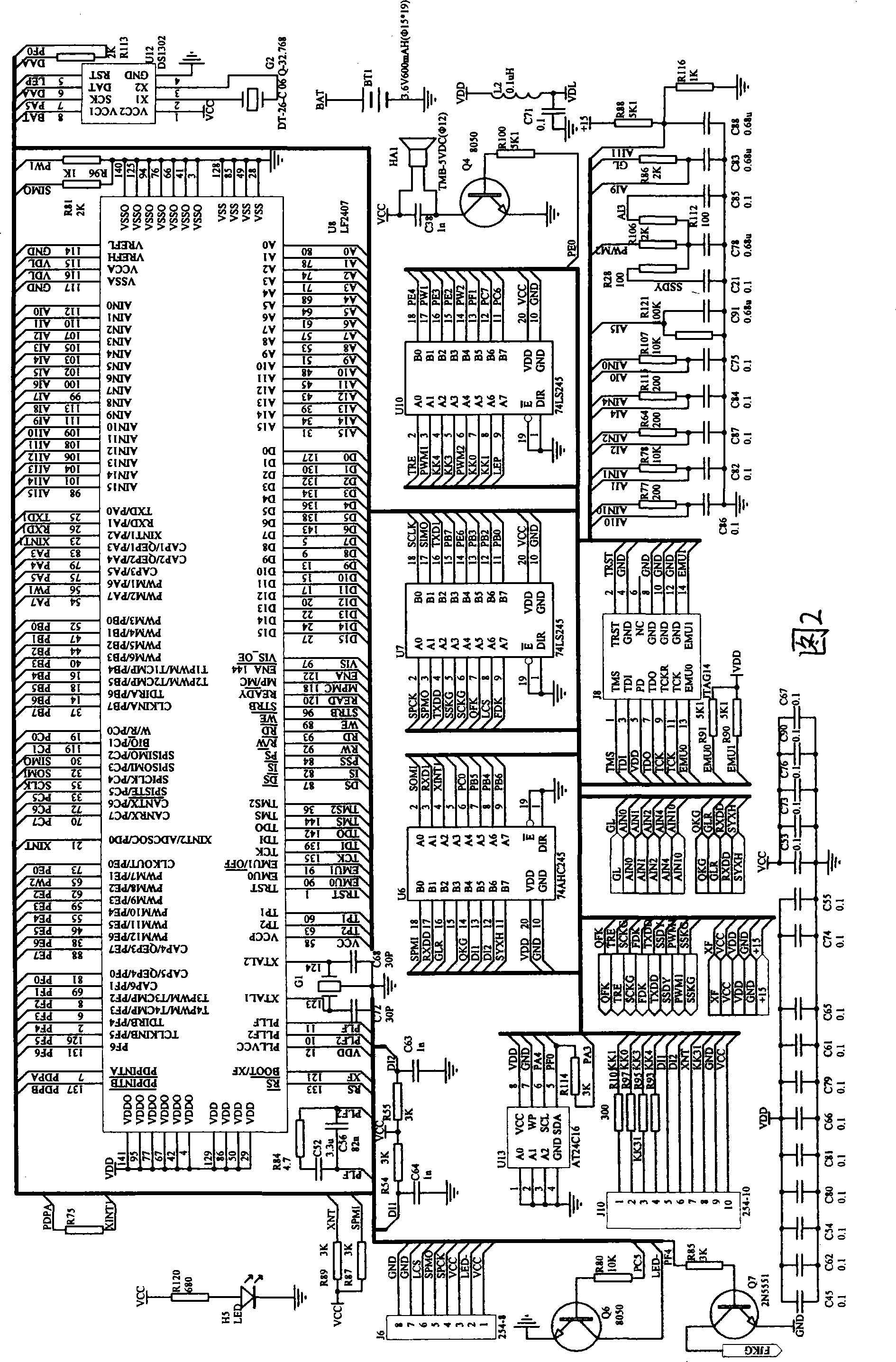

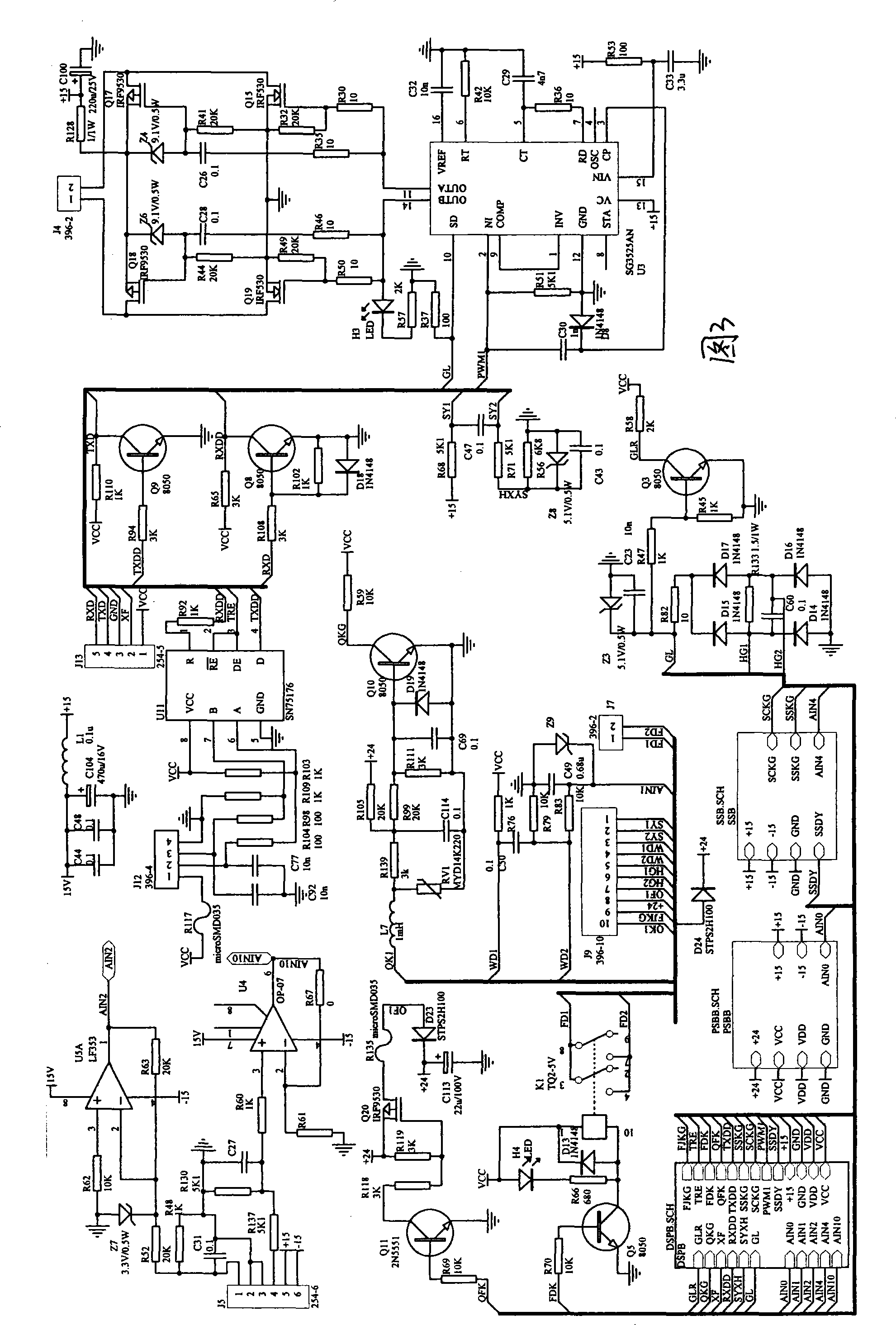

[0032] The control circuit includes a DSP processor, a signal sampling circuit whose output terminal is connected to the signal acquisition port of the DSP processor, a high-frequency pulse arc starting circuit, and a transmitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com