Dual-hydraulic drum type braking device

A brake device, dual hydraulic technology, applied in hydraulic drum brakes, brake actuators, gear shifting mechanisms, etc., can solve the problems of concentrated heating of brake shoes, affecting the braking effect of brake shoes, etc., and achieve braking performance. Good, the braking effect is obvious, the effect of improving the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

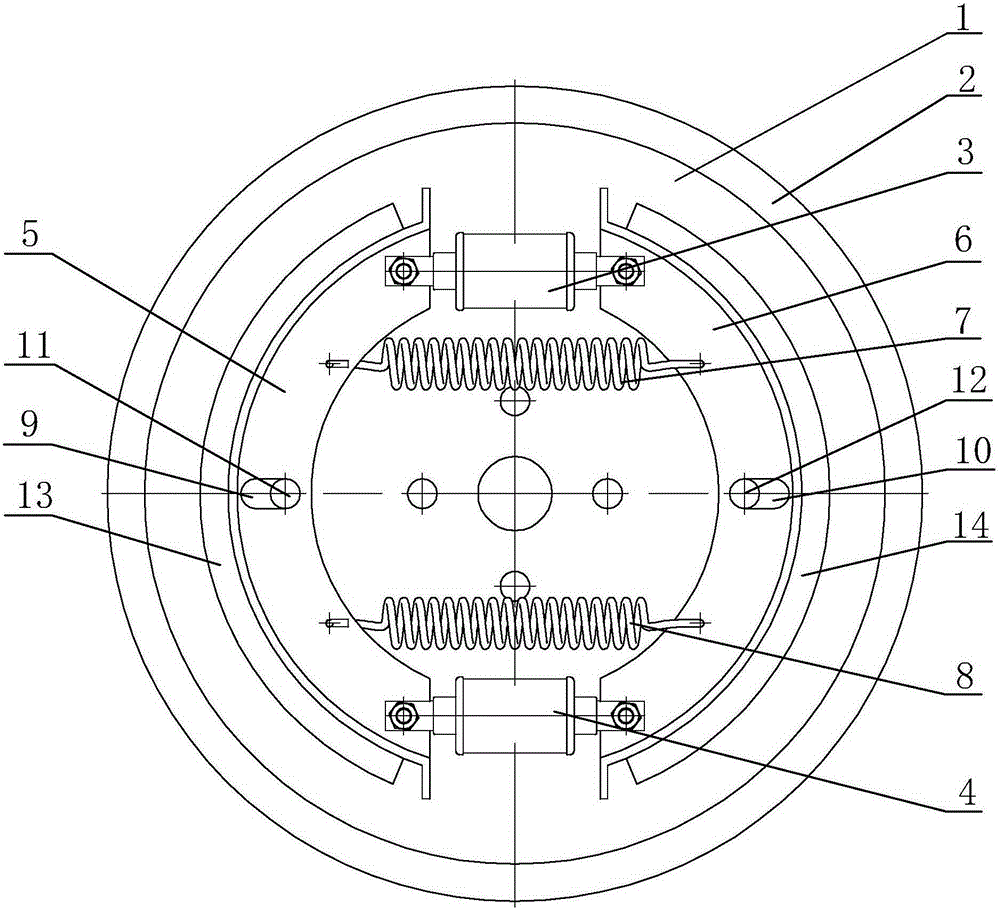

[0014] like figure 1 As shown, the present invention is a dual-hydraulic drum brake device, which includes a brake disc 1 sheathed in a wheel hub 2, a left brake shoe 5 and a right brake shoe 6 are arranged symmetrically in the brake disc 1, and the left brake The tops of the shoe 5 and the right brake shoe 6 are connected by the telescopic rod of the upper telescopic hydraulic cylinder 3, the bottom ends of the left brake shoe 5 and the right brake shoe 6 are connected by the telescopic rod of the lower telescopic hydraulic cylinder 4, and the upper telescopic hydraulic cylinder 3 and the lower telescopic hydraulic cylinder 4 are arranged symmetrically up and down, and preferably, the upper telescopic hydraulic cylinder 3 and the lower telescopic hydraulic cylinder 4 are bidirectionally acting two-stage telescopic hydraulic cylinders. The two ends of the upper tension spring 7 are respectively connected with the upper ends of the left brake shoe 5 and the right brake shoe 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com