Wedge actuating drum type brake

A drum brake and actuation technology, applied in the direction of hydraulic drum brake, drum brake, brake type, etc., can solve the troublesome task of disassembling the hub and brake drum assembly, uneven wear of the lining, and the inability of the piston 42 full use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

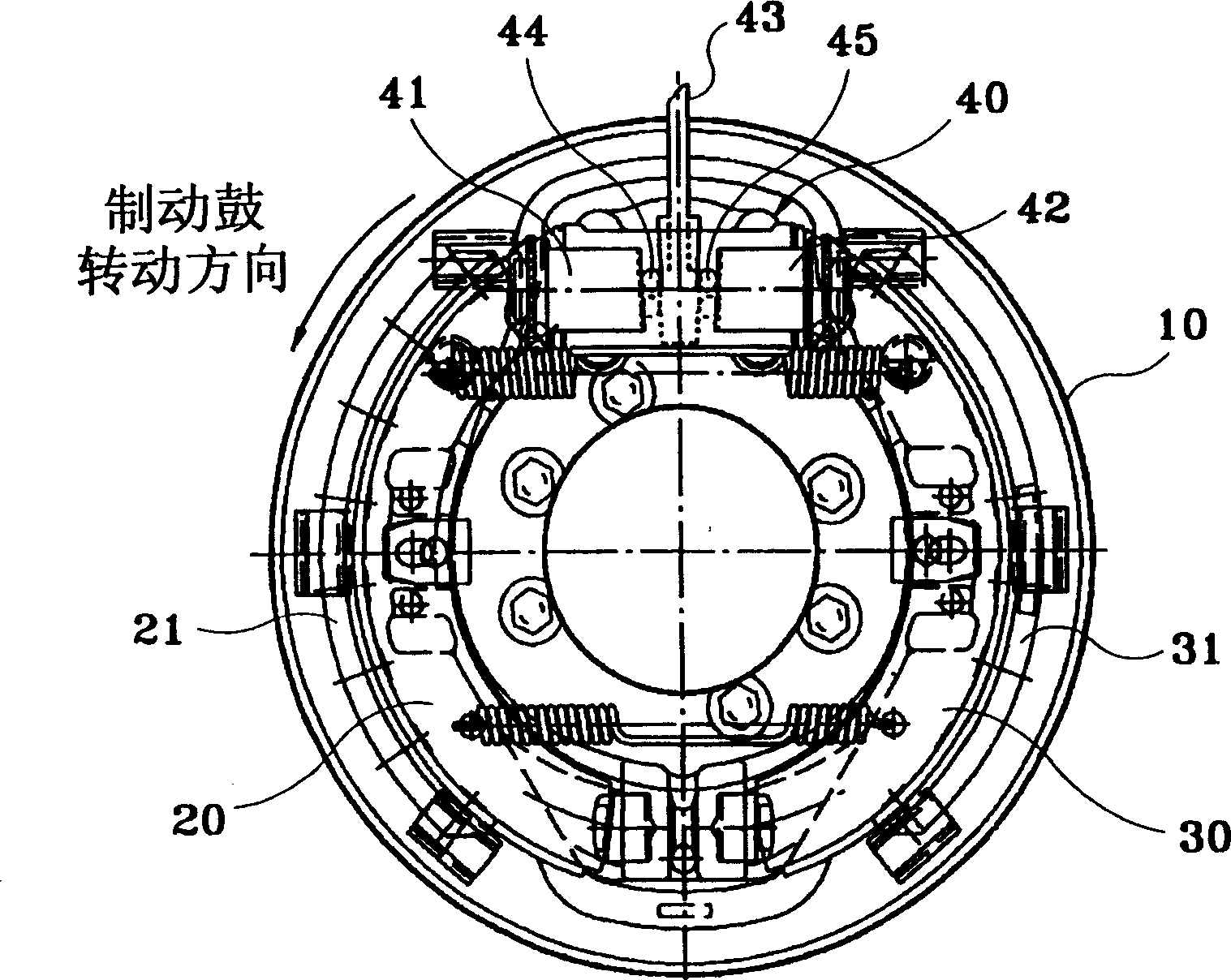

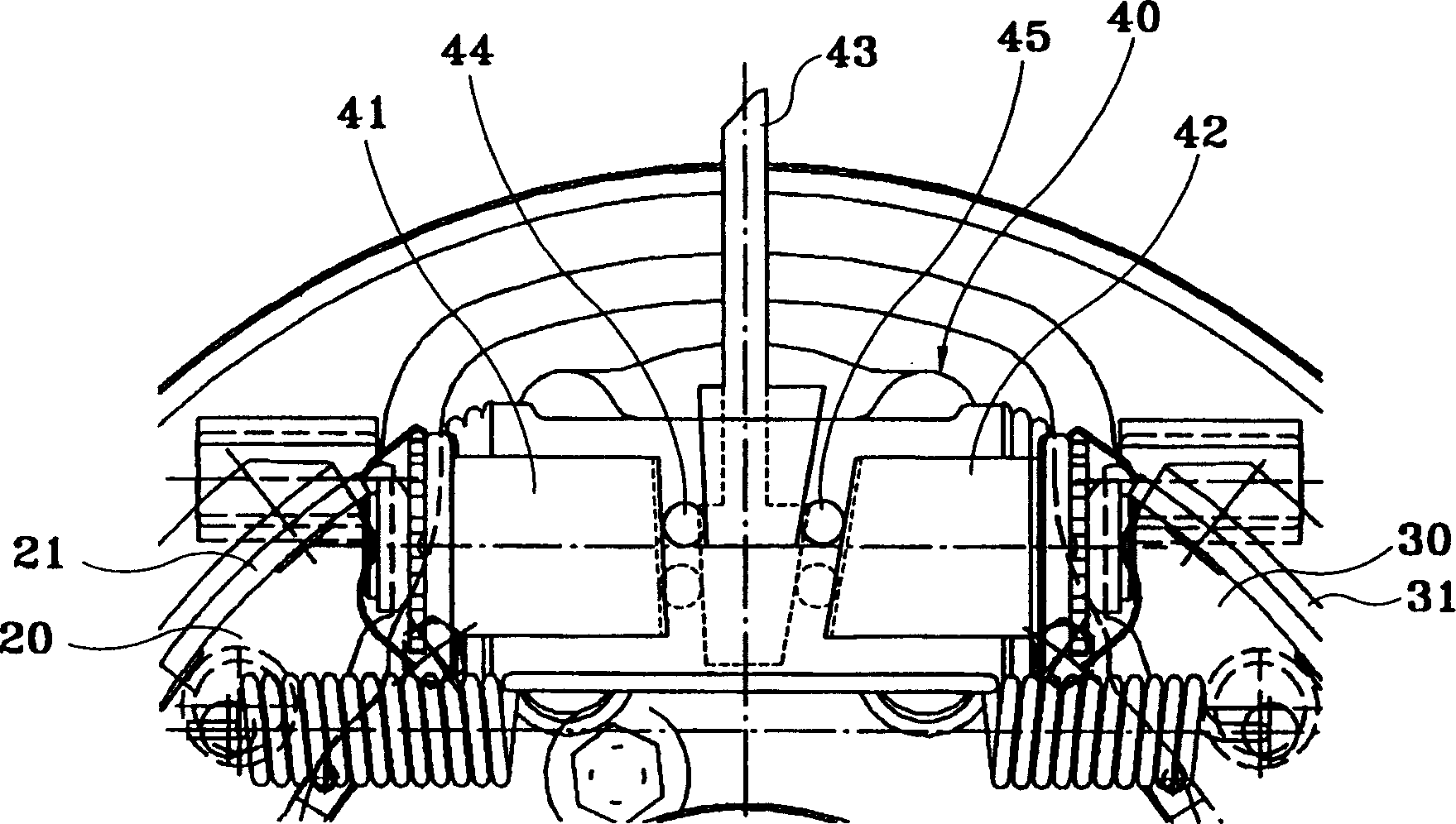

[0020] Such as image 3 As shown, when forming the two slopes 41 and 42 of the support wedge 43 , the inclination angle on the side of the trailing shoe 30 is larger than that on the side of the leading shoe 20 .

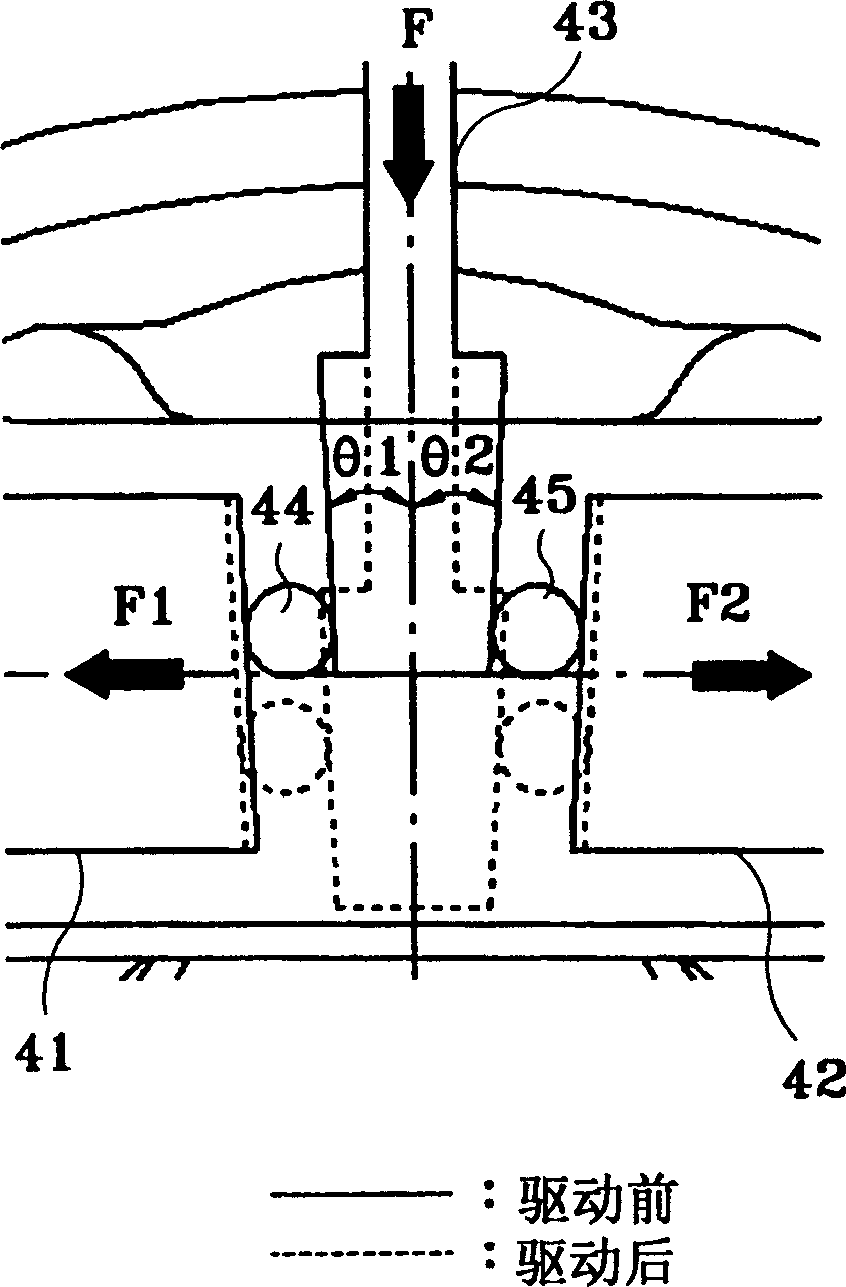

[0021] Such as Figure 4 As shown, the inclination angles θ1 and θ2 with respect to the axis of the wedge 43 are made θ1<θ2, and the inclination angles of the end faces of the two pistons 41 and 42 are also different to correspond to the inclination angle of the wedge 43 .

[0022] Balls 44 and 45 are placed between wedge 43 and pistons 41 , 42 as in conventional techniques.

[0023] As mentioned above, in the conventional method, the forces F1 and F2 of the pistons 41 and 42 are respectively: F1=F / 2*tanθ1, F2=F / 2*tanθ2, therefore, if θ1<θ2, then F1

[0024] That is to say, if the inclination angle becomes larger, the thrust force of the pistons also becomes larger. Therefore, the thrust force of the piston 42 associated with the slave shoe 30 is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com