Drum brake and brake shoe for one such brake

a technology of drum brakes and shoes, which is applied in the direction of mechanically actuated brakes, fluid actuated drum brakes, brake elements, etc., can solve the problems of reducing therefore the stability of the vehicle, and the replacement of the drum brake shoe is complicated and the braking torque stability is improved. , the effect of improving the stability of the braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

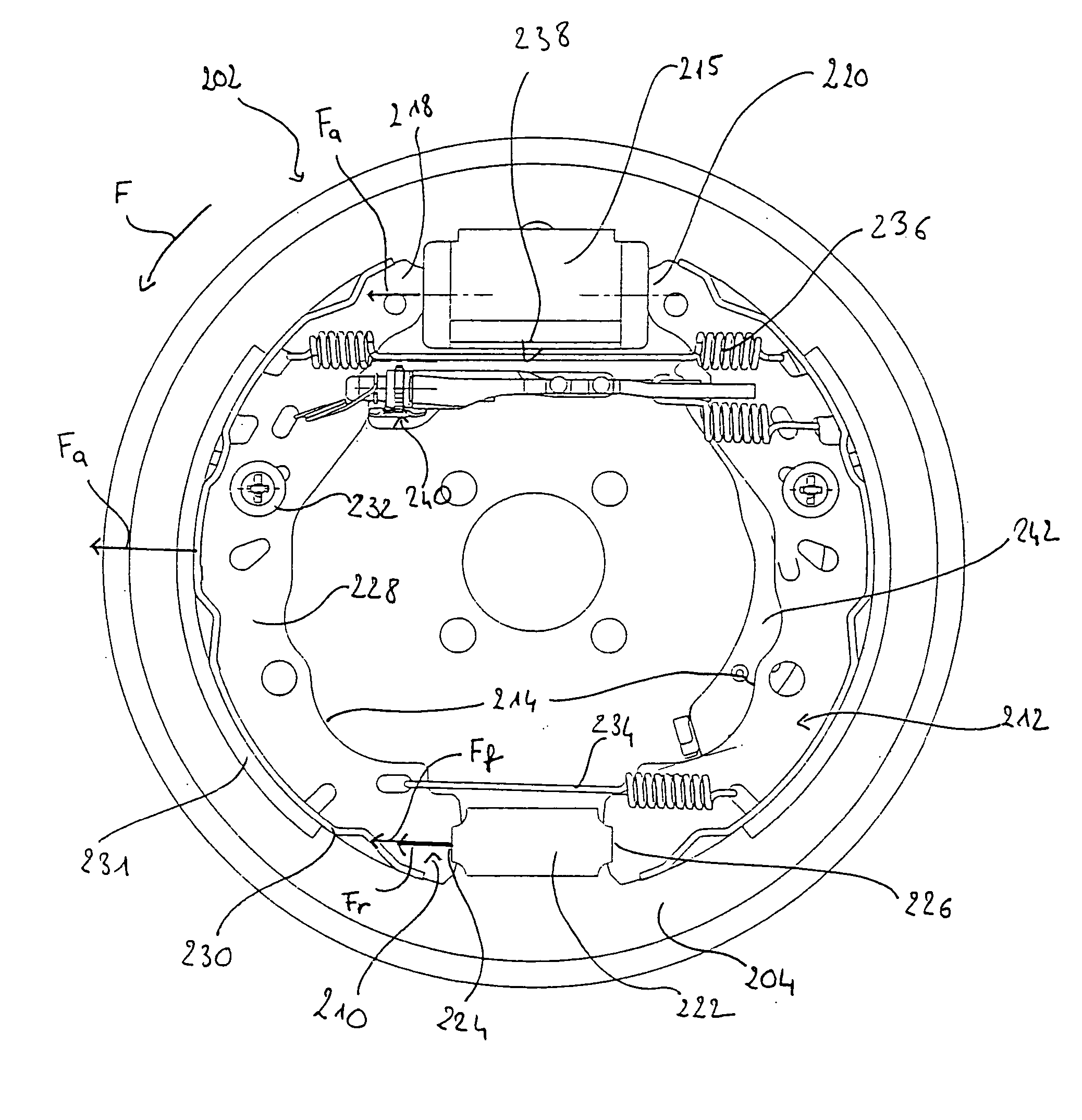

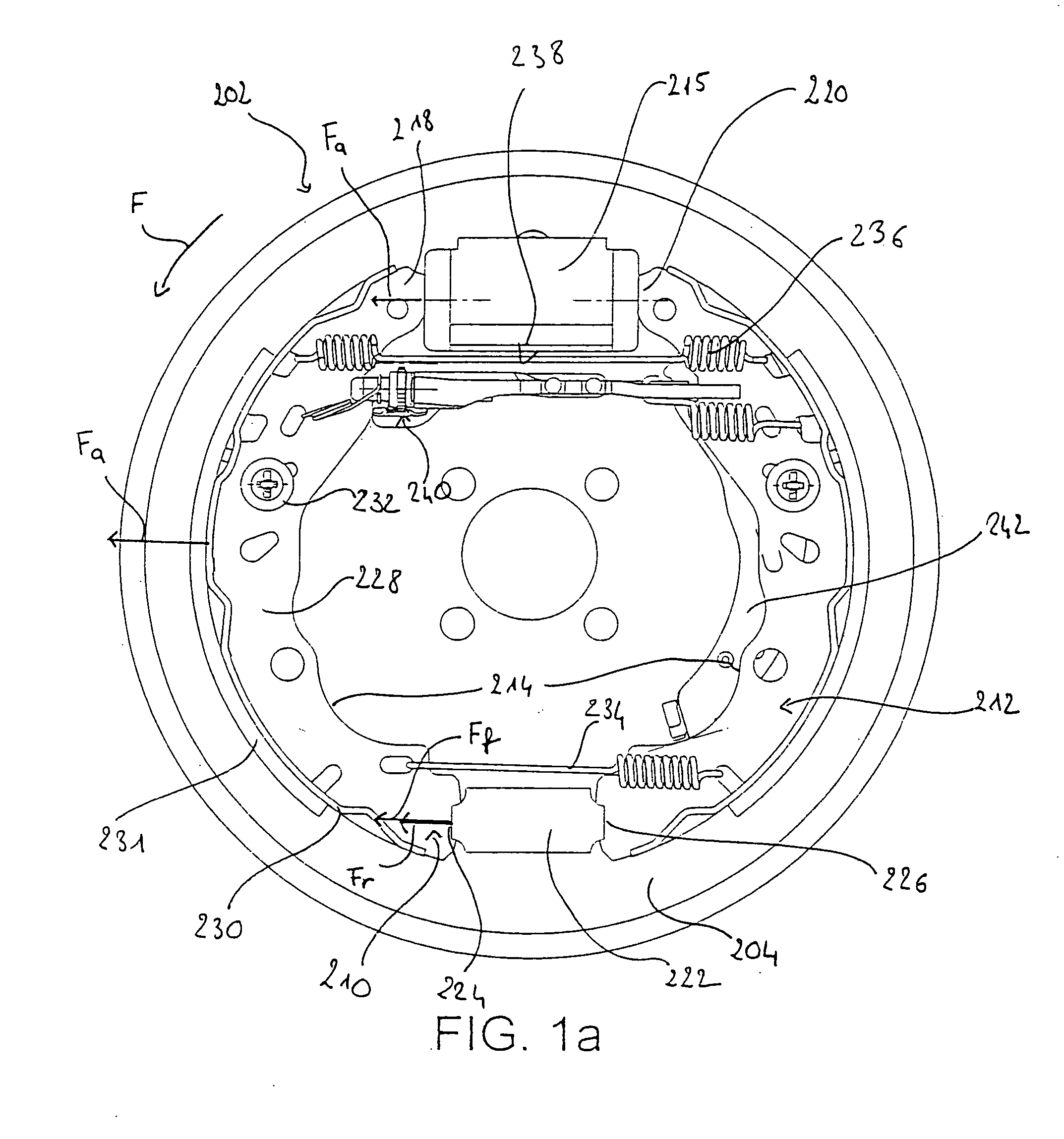

[0032]FIG. 1a shows a drum brake 202 of known type including a disk-shaped plate 204 organized to be fixed to a wheel arm of a vehicle, first and second shoes 210, 212 that are substantially circular arcuate in shape and that are mounted on the plate, their convex portions 214 facing towards the outside of the plate, and their convex portions 216 facing each other, a wheel cylinder 215 secured to the plate 204 and disposed between respective first ends 218, 220 of the first and second shoes 210, 212, and abutment means 222 secured to the plate 204 and disposed between second ends 224, 226 of the first and second shoes, and a drum (not shown) secured to the wheel and surrounding the convex portions 214 of the shoes 210, 212 with clearance.

[0033] Since the first and second shoes 210, 212 are symmetrical, only the first shoe is described below, while also specifying what is specific to it relative to the second shoe 212.

[0034] The first shoe 210 comprises a crescent-shaped rim 228, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com