Actuator driven by gear having axial guide rail, and drum brake and braking device provided with same

A drum brake and braking device technology, applied in the field of drum brakes and actuators, can solve problems such as difficult adjustment and uneven wear, and achieve the effects of reducing tooth wear, precise positioning, and reducing production and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

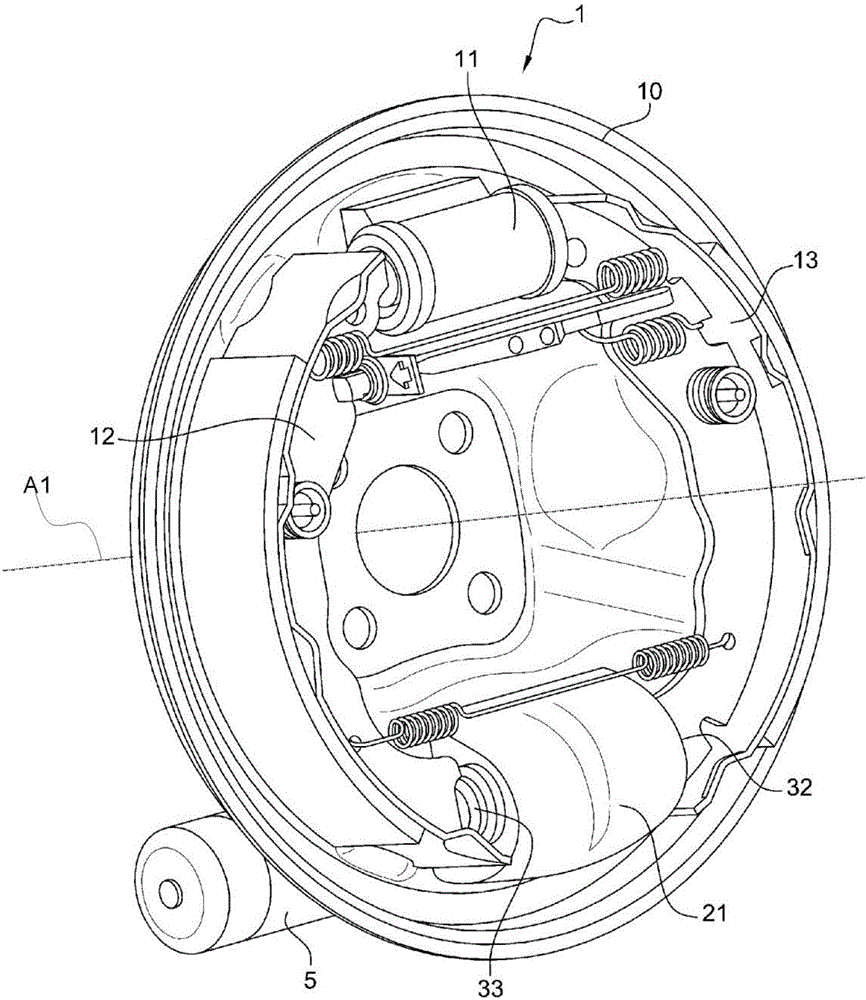

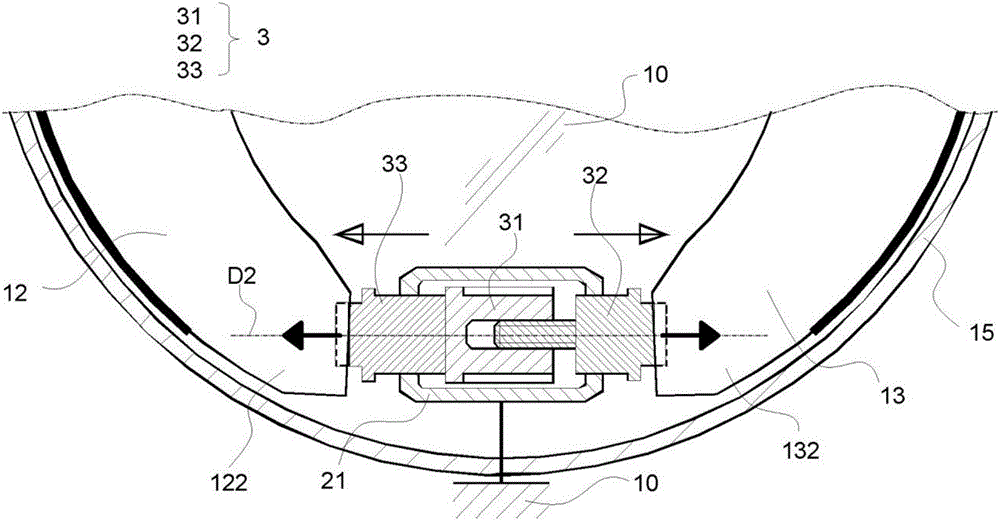

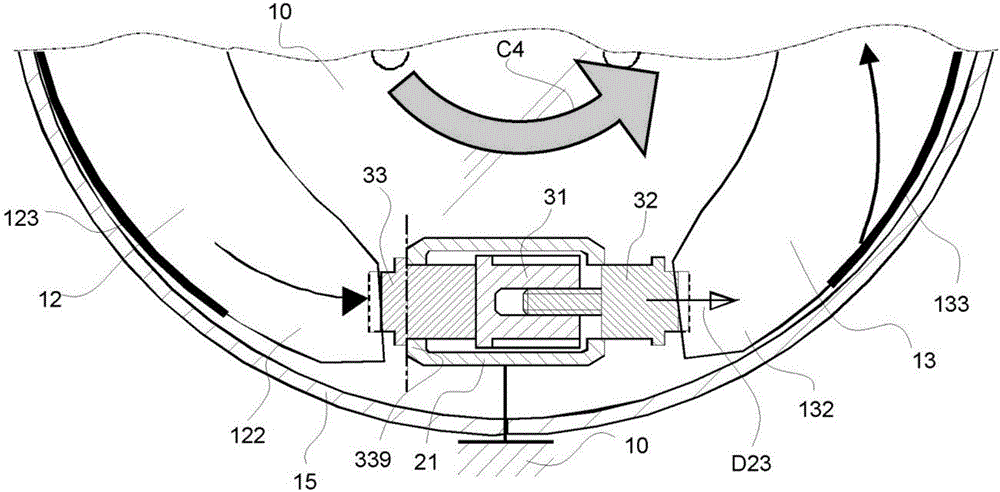

[0046] In the embodiment presented here, the drum brake 1 comprises a linear actuator 2 and a second actuator 11 according to the invention, each actuator allowing different modes of operation. The two actuation modes are controlled to provide two different braking functions.

[0047] In this embodiment, a linear actuator 2 according to the invention is used to provide the parking or emergency braking function, and a second actuator 11 (for example a hydraulic wheel of known type with two opposed pistons) Cylinder) is used to provide the service braking function.

[0048] The drum brake 1 generates a braking torque between the drum 15 and the base plate 10 , wherein the drum 15 and the base plate 10 move in rotation relative to each other about the axis of rotation A1 . Typically, the floor 10 is rotatably fixed to the chassis of the vehicle, usually via a suspension shaft or half shaft. The drum is coupled to the wheel, fixed in translation and guided in rotation about the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com