Vehicular ring-shaped brake

A kind of brake and ring technology, applied in the direction of brake type, brake components, hydraulic drum brake, etc., can solve the problems of the return spring falling into the brake drum easily, the wear of the piston cylinder, the loss of braking of the car, etc. The effect of reduced braking distance, reduced braking distance, and enhanced braking capacity of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

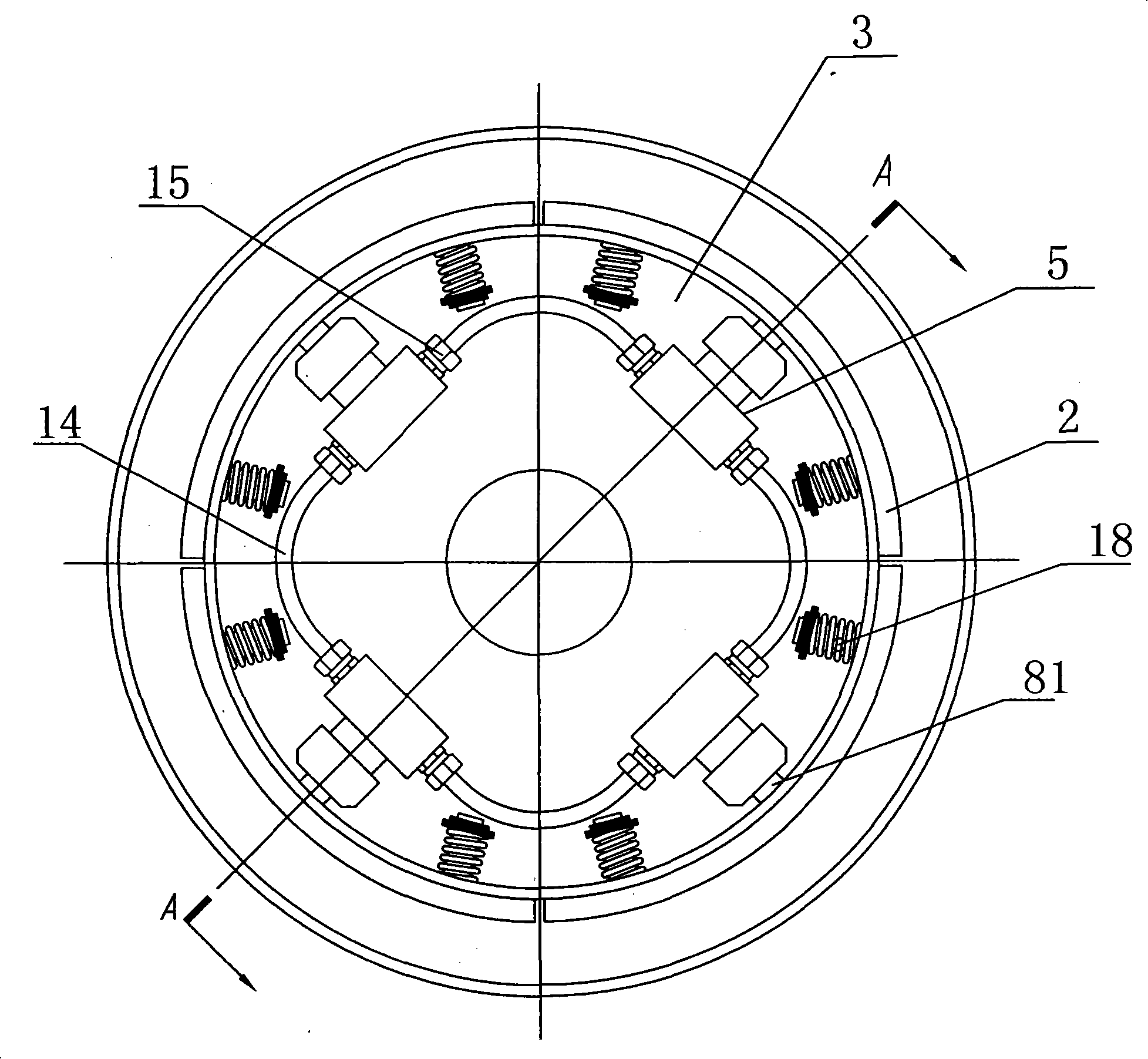

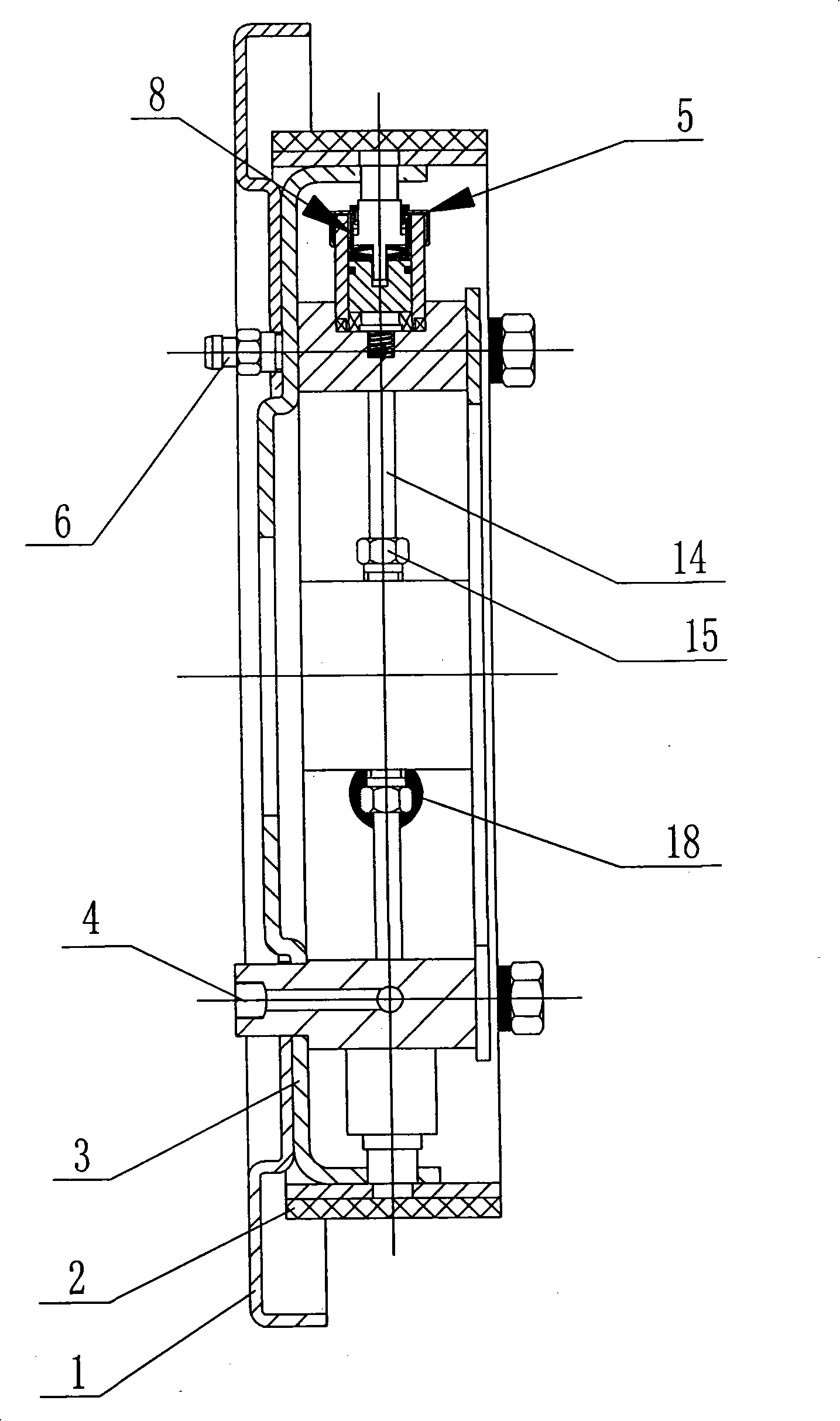

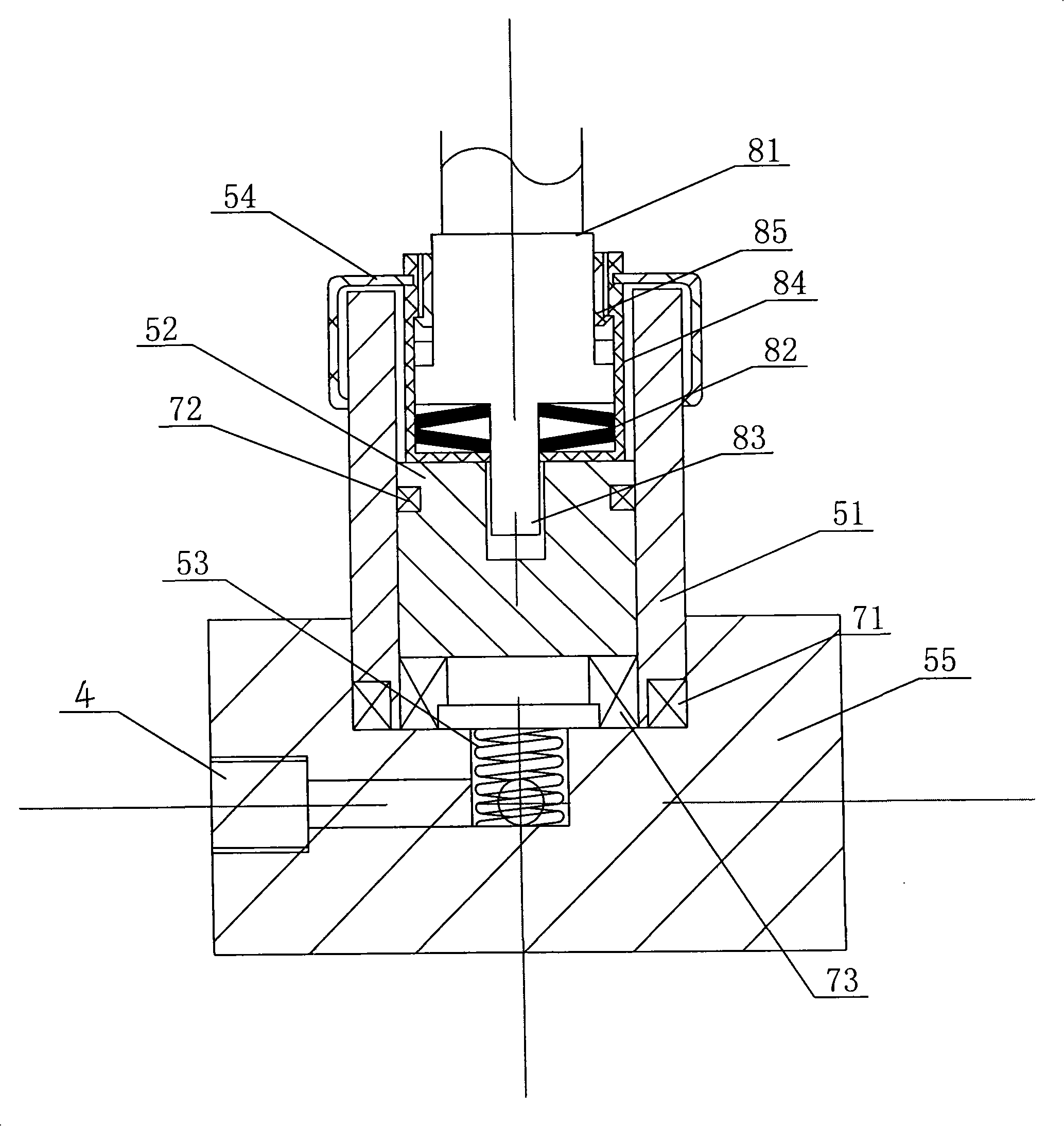

[0050] Example 1, see figure 1 , figure 2 , image 3 , a kind of annular brake for vehicles, including a brake base plate 3, a friction plate 2, four piston cylinder assemblies 5 are fixedly connected on the brake base plate 3, a seal spring assembly 8 is arranged in the piston cylinder assembly 5, and the seal spring The outer end of the telescopic rod 81 of the assembly 8 is fixedly connected with the friction plate 2; the piston cylinder assembly 5 is connected with the sealed annular oil pipe 14 through the oil pipe connecting nut 15; the brake base plate 3 and the friction plate 2 are also connected Return spring 18 is provided. The sealing spring assembly mainly refers to the disc spring 82, the telescopic rod 81, the lock ring 85, and the sealing cylinder 84 of the spring assembly. No locking when braking. The sealing spring assembly 8 is provided with a disc spring 82 above the piston 52 in the oil cylinder 51, and a telescopic rod 81 is provided above the disc sp...

Embodiment 2

[0051] Example 2, see Figure 4 , the same as in Embodiment 1, the number of piston cylinder assemblies 5 is 12.

[0052] When the automobile brakes, the brake oil enters the oil inlet 4 of the piston cylinder assembly 5 under the pressure of the automobile brake master cylinder, enters the piston cylinder assembly 5, and passes the piston 52 in the piston assembly through the inner hole of the piston cylinder assembly. Push out, the piston 52 pushes the sealing spring assembly 8 again, and the sealing spring assembly 8 pushes out the friction plate 2 again, and the friction plate 2 contacts with the brake drum to realize braking. When the brake is released, the friction plate 2 is under the pressure of the return spring 18 The back pressure seal spring assembly 8 seal spring assembly 8 presses the piston 52 again, and the piston (52) presses the brake oil back to the brake master cylinder through the oil inlet (4) to complete braking. Wherein the effect of exhaust nozzle (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com