Hydraulic brake

A technology of hydraulic brakes and brake parts, which is applied to hydraulic drum brakes, brake types, axial upward brakes, etc., can solve the problems of low safety factor, heat generation, easy wear, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

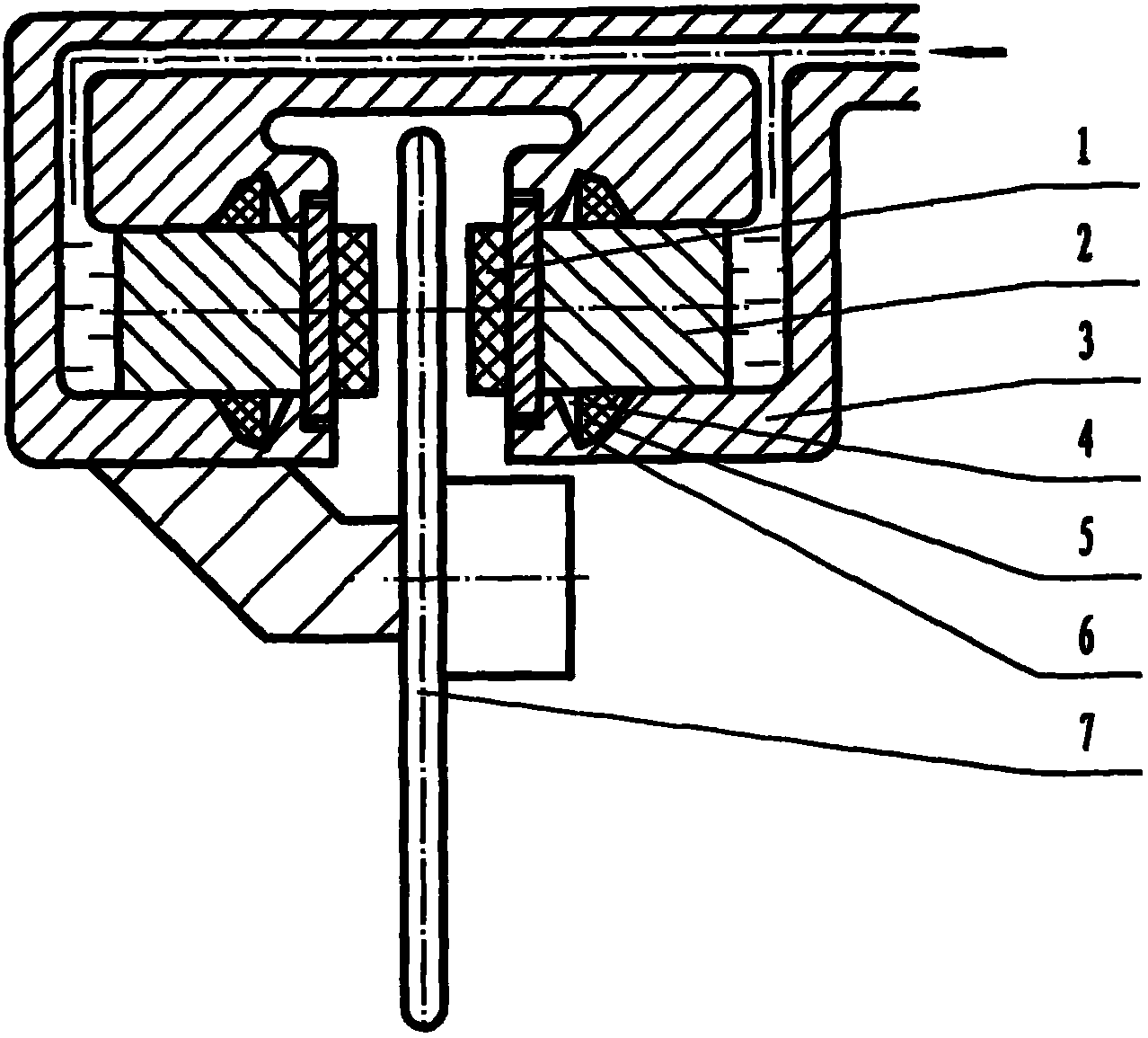

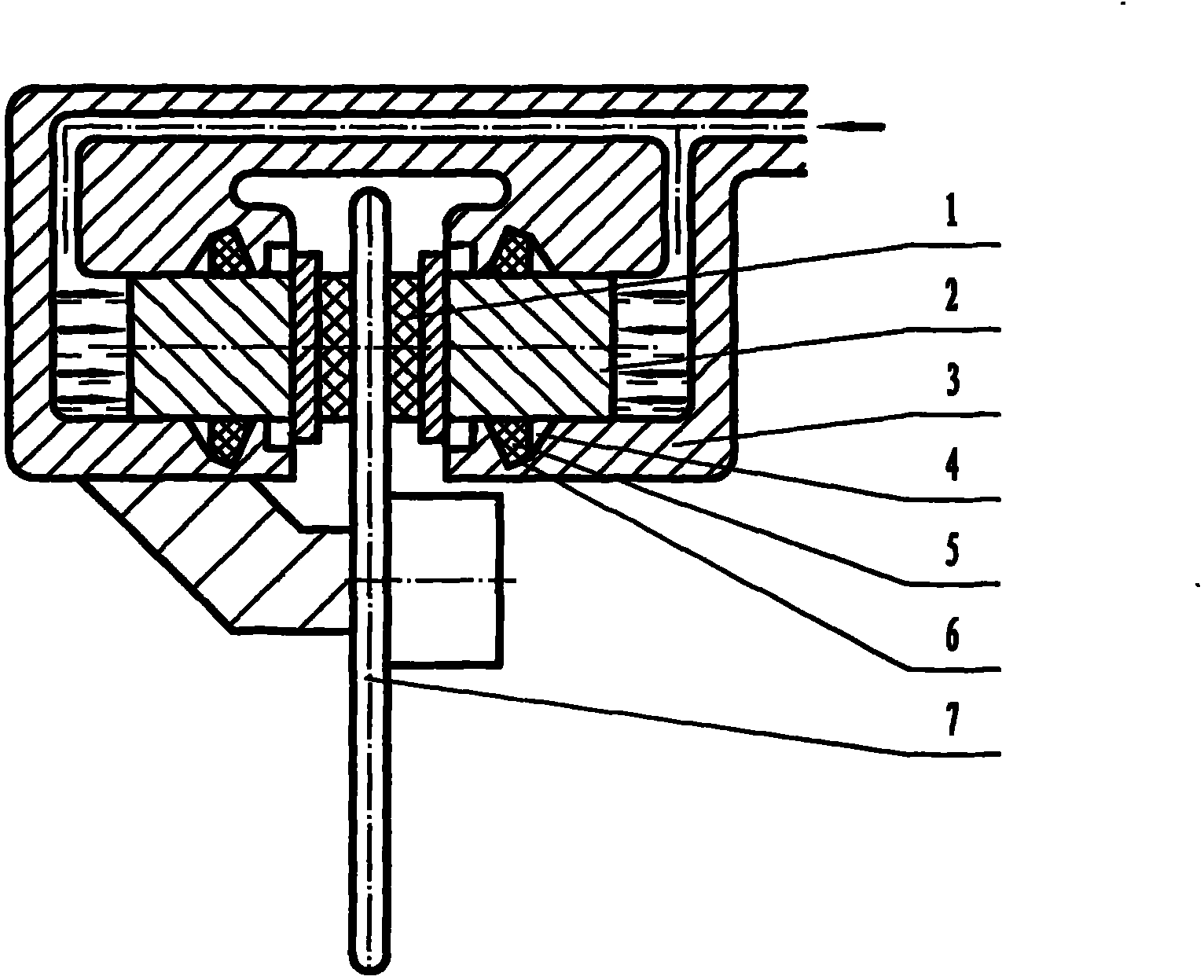

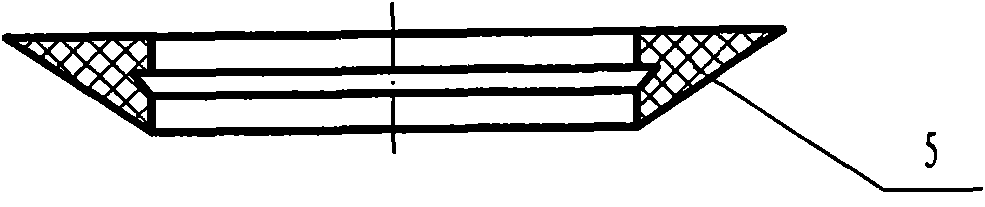

[0030] exist figure 1 Among them, the hydraulic brake is composed of a brake cylinder 3, a seal ring groove 6, a seal ring 5, a piston 2, a brake friction part 1, and a braked part 7, which are sequentially installed and connected, wherein the seal ring 5 is connected by the piston 2 and the seal ring The bottom of the groove 6 is extruded and sealed to be divided into an inner chamber and an outer chamber. Between the outer side of the sealing ring 5 and the wall of the sealing ring groove 6, a space 4 for the axial movement of the sealing ring 5 is provided. The axial movement space 4 is a coaxial circular ring, and the section is approximately trapezoidal or approximately "V"-shaped or rectangular, preferably "V"-shaped, such as figure 1 , Figure 6 , Figure 7 , Figure 9 , Figure 15 shown. The sealing ring 5 is a circular ring, installed in the sealing ring groove 6, squeezed by the piston 2 and the bottom of the sealing ring groove 6, and is basically statically se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com