Vehicle hydraulic master cylinder

A hydraulic and vehicle technology, which is applied to vehicle components, hydraulic brake transmissions, cylinders, etc., can solve the problems of increasing the piston's invalid stroke and biting the lip part of the inner circumference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

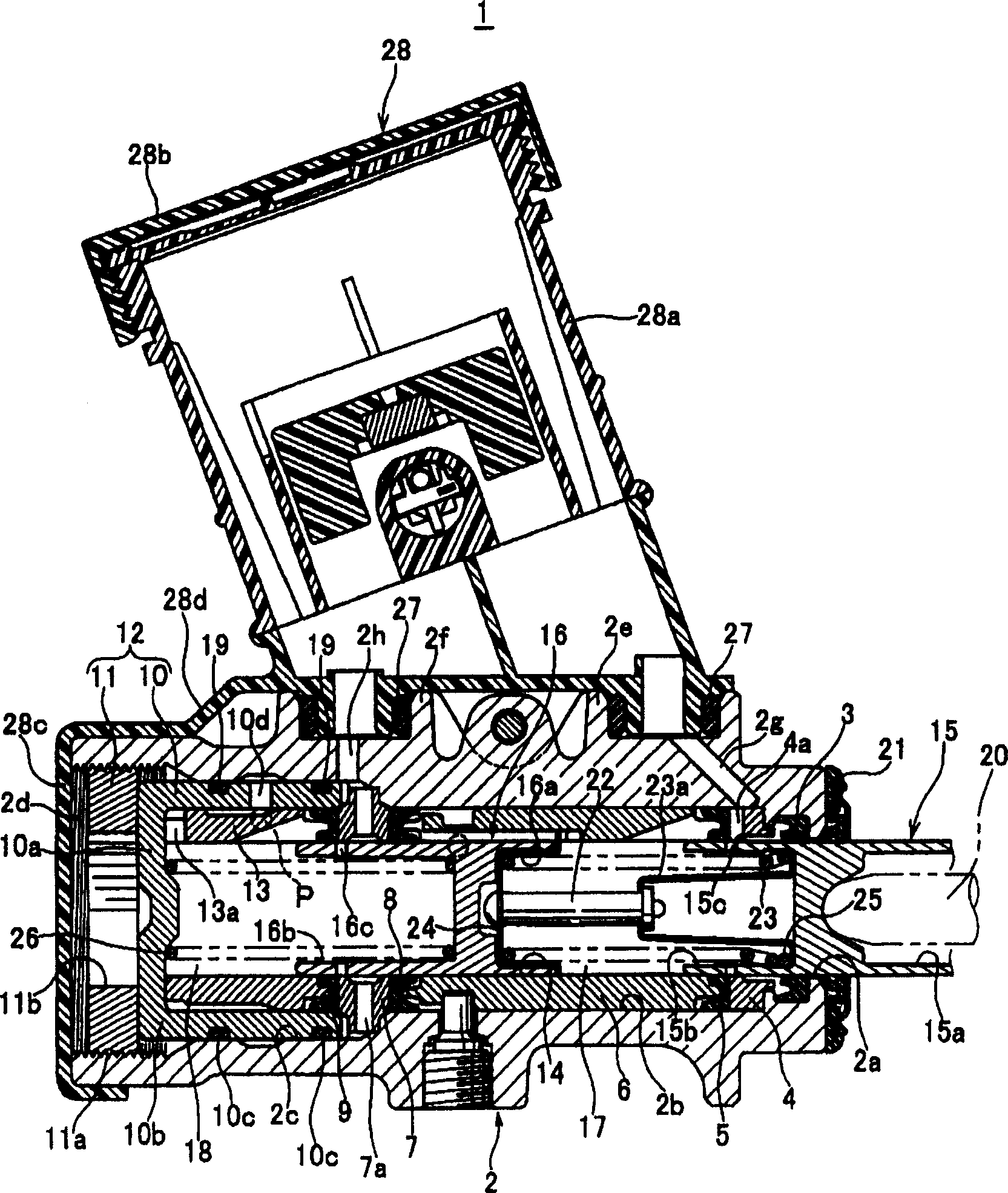

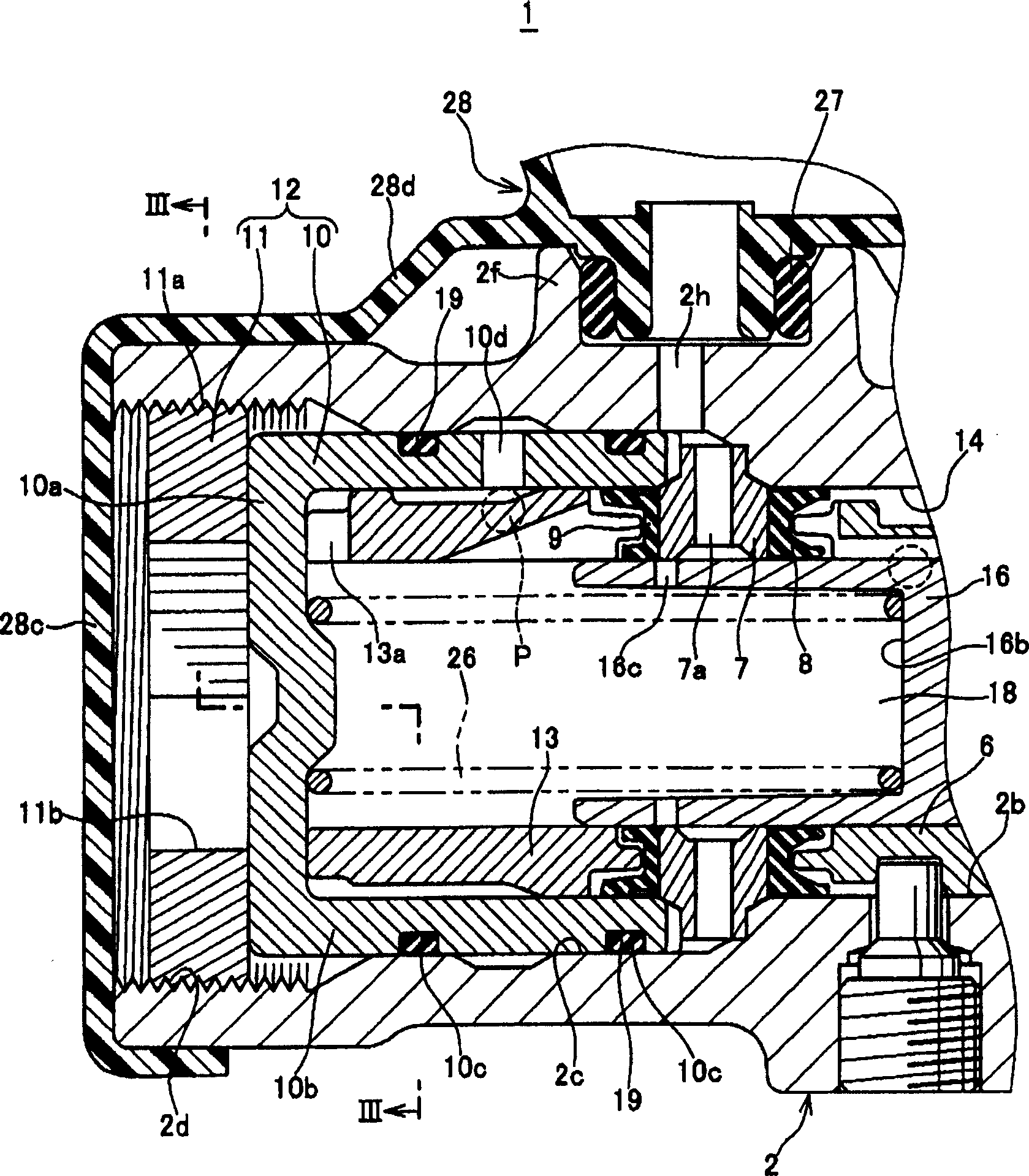

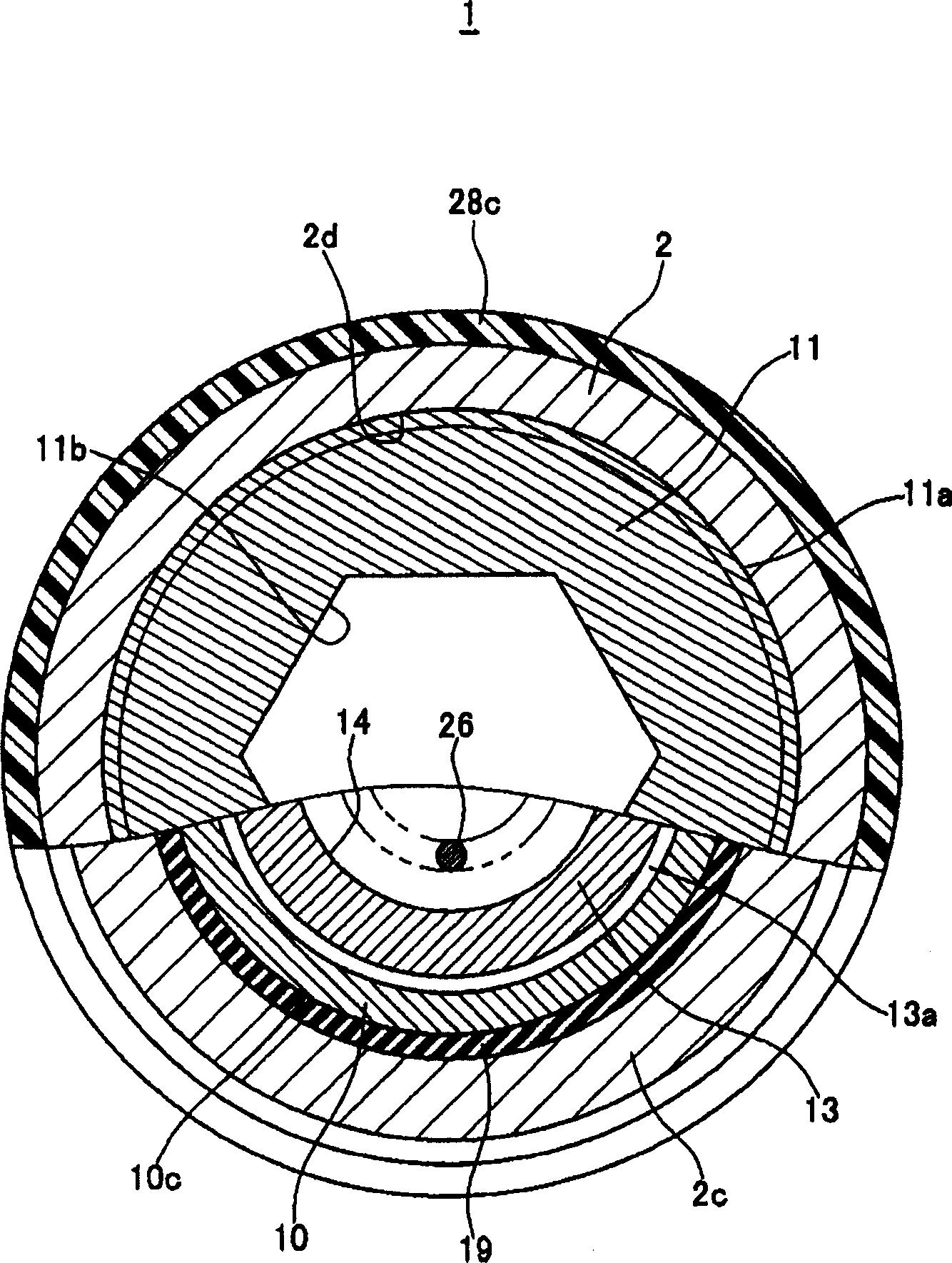

[0025] Embodiments of the present invention will be described below with reference to the drawings. figure 1 is a cross-sectional view of a piston-type hydraulic master cylinder of a vehicle, wherein the cylinder body 2 of the master cylinder 1 is formed into a cylindrical shape with both ends open, including a distal small diameter portion 2a formed at its front end, a diameter slightly larger than the distal small diameter A small-diameter cylinder bore 2b of the portion 2a, and a medium-diameter cylinder bore 2c and a large-diameter cylinder bore 2d formed at the rear of the cylinder main body. The first cup-shaped seal 3 is installed in the joint groove of the distal small-diameter part 2a, and the second cup-shaped seal 5 supported on the seal support 4 and the first piston guide 6 are installed in the small-diameter cylinder. in bore 2b. A seal support 7 is installed between the small-diameter cylinder bore 2b and the medium-diameter cylinder bore 2c, and a third cup se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com