Multielement resin base carbon compound disc-type braking pad and preparation method thereof

A multi-component resin and disc brake technology, which is applied in the field of auto parts, can solve the problems of poor high temperature resistance, general high temperature resistance, and poor elasticity of brake pads by enhancing the elasticity of modified phenolic resin, so as to improve the high temperature resistance , high specific strength, low brake dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

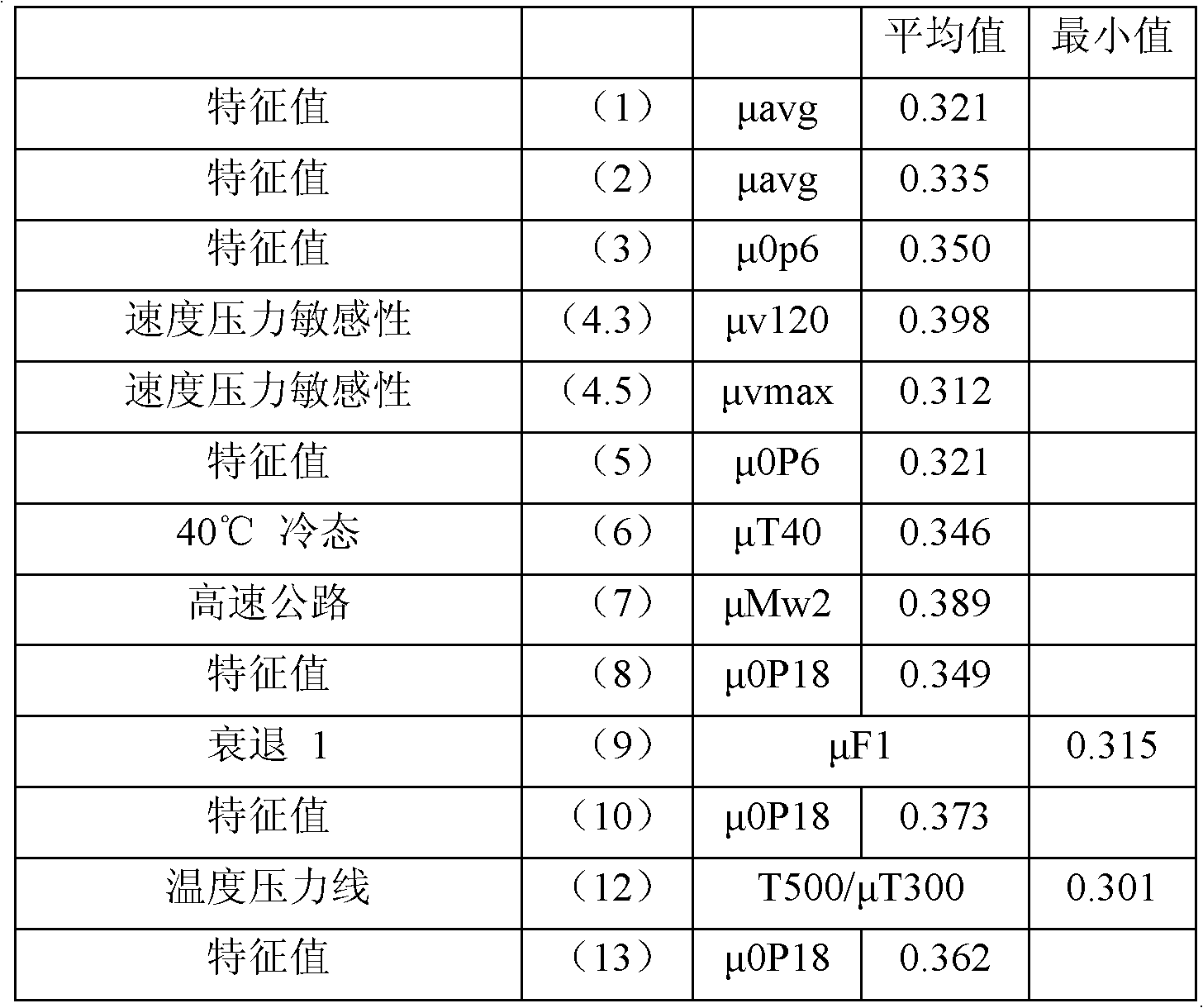

Embodiment 1

[0018] Formula (mass percentage): 5% unmodified phenolic resin, 5% silicone modified phenolic resin, 5% polyacrylate modified phenolic resin, 3% polyacrylonitrile carbon fiber carbon fiber, 5% artificial particle graphite, natural flake graphite 5%, granular coke 5%, silicon carbide 1%, aramid pulp 1%, composite mineral fiber 8%, steel fiber 17%, copper powder 5%, ferrous sulfide 5%, barium sulfate 30%. Among them, the flow distance of unmodified phenolic resin is 23mm, the gelation time is 96S, the flow distance of silicone modified phenolic resin is 18mm, the gelation time is 100S, and the flow distance of polyacrylate modified phenolic resin is 25mm , the gelation time is 85S, the fiber length of polyacrylonitrile carbon fiber carbon fiber is 2.0mm, the particle size of artificial granular graphite is 40 mesh, the particle size of natural flake graphite is 100 mesh, the granular coke is 40 mesh, and the particle size of silicon carbide is 500 mesh The aspect ratio of aramid...

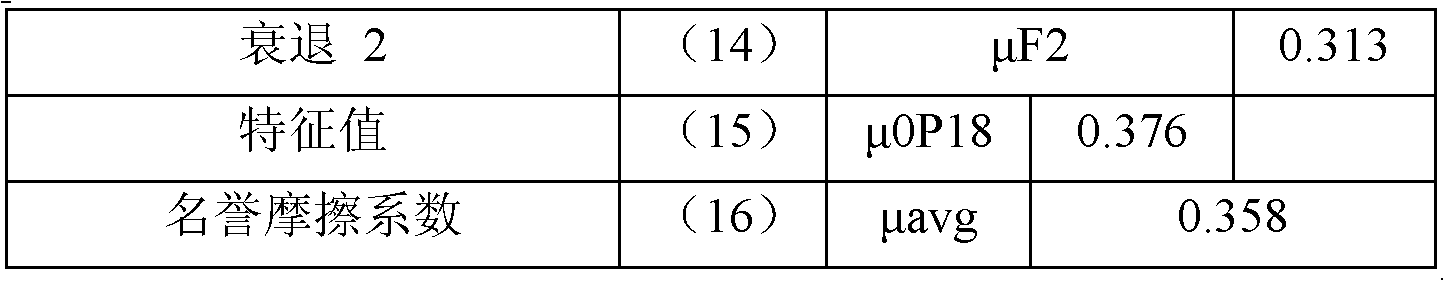

Embodiment 2

[0033]Proportion (mass percentage): unmodified phenolic resin 4%, silicone modified phenolic resin 7%, polyacrylate modified phenolic resin 7%, polyacrylonitrile carbon fiber 5%, artificial particle graphite 8%, natural flake graphite 8%, granular coke 8%, silicon carbide 3%, aramid pulp 3%, composite mineral fiber 6%, steel fiber 15%, copper powder 3%, ferrous sulfide 3%, barium sulfate 20%. Among them, the flow distance of unmodified phenolic resin is 23mm, and the gelation time is 96S; the flow distance of silicone modified phenolic resin is 18mm, and the gelation time is 100S; the flow distance of polyacrylate modified phenolic resin is 25mm , the gelation time is 85S, the fiber length of polyacrylonitrile carbon fiber is 2.0mm, the particle size of artificial granular graphite is 40 mesh, the particle size of natural flake graphite is 100 mesh, the granular coke is 40 mesh, and the particle size of silicon carbide is 500 mesh , the aspect ratio of aramid pulp is 50, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com