Liquid-cooling drum brake with cooling liquid circulation control system

A circulation control and coolant technology, applied in the direction of brake types, brake parts, mechanical equipment, etc., can solve the problems of difficulty in fully exerting functions, poor thermal stability, low heat dissipation capacity, etc., and achieve thermal stability and good heat dissipation , good thermal stability and heat dissipation, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

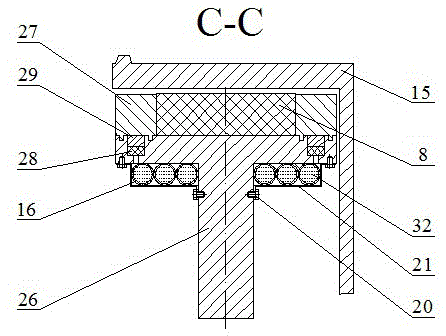

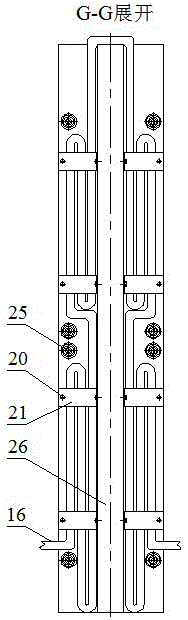

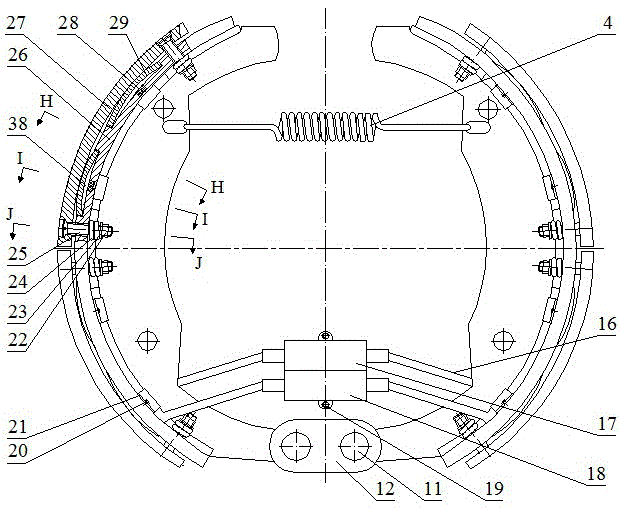

[0038] Liquid-cooled drum brakes with coolant circulation control systems include liquid-cooled drum brakes and coolant circulation control systems such as Figure 4 ?18.

[0039] In a liquid-cooled drum brake with a coolant circulation control system, the liquid-cooled drum brake includes a cylinder 1, a piston 3, a return spring 4, a bottom plate connecting bolt 5, a friction plate 8, a positioning pin 10, a support pin 11, Support pin gasket 12, support pin nut 13, liquid-cooled brake base plate 14, liquid-cooled brake drum 15, cooling pipe 16, liquid inlet tee 17, liquid outlet tee 18, tee bolt 19, baffle bolt 20 , baffle plate 21, heat transfer plate nut 22, heat transfer plate gasket 23, heat transfer plate spring 24, heat transfer plate bolt 25, liquid-cooled brake shoe 26, heat transfer plate 27, heating resistor 28 and thermal plate 29 ; On the basis of the air-cooled drum brake, replace the air-cooled brake base plate 6, the air-cooled brake drum 9 and the air-coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com