Nonmetal friction material for vehicle disc brake and preparation method and application thereof

A disc brake and friction material technology, applied in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problem of high cost of NAO type friction materials, high price of high temperature resistant organic fibers, low friction coefficient and thermal stability. and other problems, to achieve the effect of excellent thermal recession performance, excellent thermal recession performance and high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

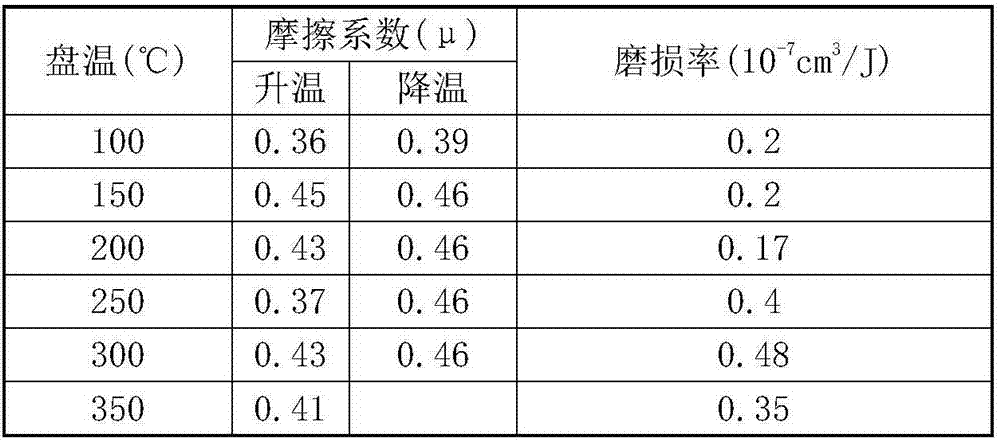

Embodiment 1

[0031] A non-metallic friction material for automobile disc brakes. The friction material is composed of the following proportions in terms of mass fraction: 8 parts phenolic resin; 20 parts mineral fiber; 2 parts carbon fiber; 2 parts aramid fiber; 10 parts ceramic fiber ; 6 parts of calcium whisker; 12 parts of barium sulfate; 3 parts of friction powder; 6 parts of vermiculite powder; 11 parts of graphite; 3 parts of coke powder; 1 part of carbon black; 8 parts of metal sulfide; 4 parts of tire powder; Molybdenum sulfide 4 parts.

[0032] Among them, barium sulfate is used as a filler.

[0033] The preparation method is as follows:

[0034] (1) After weighing the raw materials in sequence according to the above ratio, mix the raw materials uniformly with a dry mixer to obtain the mixture and store it for later use;

[0035] (2) After weighing the mixture obtained in step (1), put it into a mold preheated to 160±5°C, pressurize and maintain the pressure at a pressure of 15Mpa for 3 ...

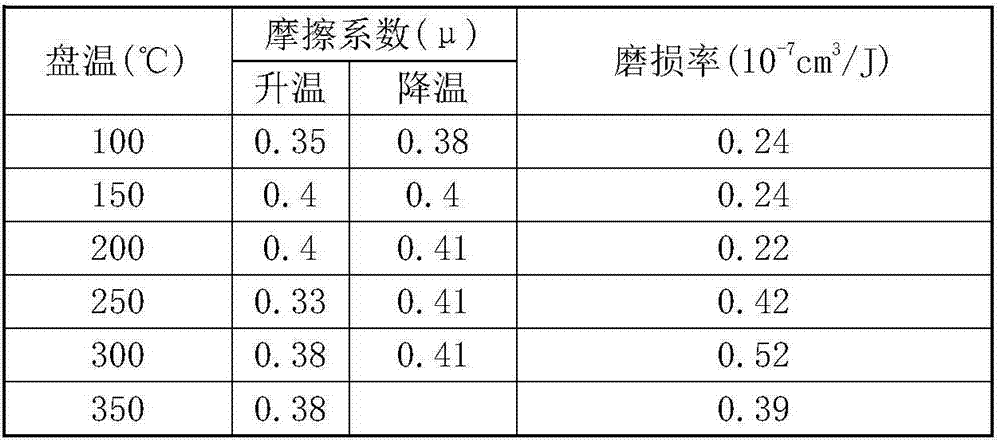

Embodiment 2

[0041] A non-metallic friction material for automobile disc brakes. The friction material is composed of 7 parts phenolic resin; 25 parts mineral fiber; 1.5 parts polypropylene fiber; ceramic fiber 6.5; calcium whisker 10 Parts; 12 parts of barium sulfate; 3 parts of friction powder; 8 parts of vermiculite powder; 11 parts of graphite; 1 part of carbon black; 11 parts of metal sulfide; 2 parts of tire powder; 2 parts of molybdenum sulfide.

[0042] Among them, barium sulfate is used as a filler.

[0043] The preparation method is as follows:

[0044] (1) After weighing the raw materials in sequence according to the above ratio, mix the raw materials uniformly with a dry mixer to obtain the mixture and store it for later use;

[0045] (2) After weighing the mixture obtained in step (1), put it into a mold preheated to 160±5°C, pressurize and maintain the pressure at a pressure of 15Mpa for 3 seconds, then release the pressure and exhaust. Relieve the pressure and exhaust for 3 seconds...

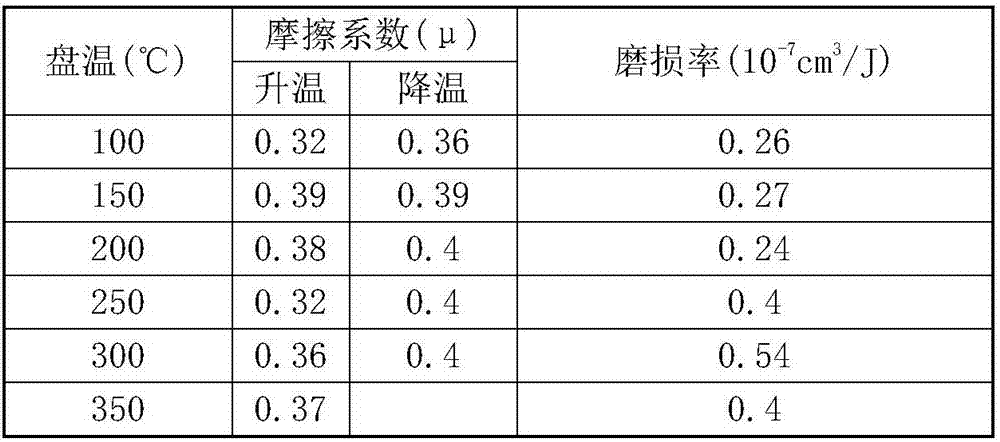

Embodiment 3

[0051] A non-metallic friction material for automobile disc brakes. The friction material is composed of the following proportions in terms of mass fraction: 7 parts of natural rubber; 18 parts of mineral fiber; 5 parts of aramid fiber; 7 parts of glass fiber; calcium whisker 6 parts; 12 parts of barium sulfate; 3 parts of friction powder; 6 parts of vermiculite powder; 11 parts of graphite; 5 parts of coke powder; 1 part of carbon black; 11 parts of metal sulfide; 4 parts of tire powder; 4 parts of molybdenum sulfide.

[0052] Among them, barium sulfate is used as a filler.

[0053] The preparation method is as follows:

[0054] (1) After weighing the raw materials in sequence according to the above ratio, mix the raw materials uniformly with a dry mixer to obtain the mixture and store it for later use;

[0055] (2) After weighing the mixture obtained in step (1), put it into a mold preheated to 160±5°C, pressurize and maintain the pressure at a pressure of 15Mpa for 3 seconds, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com