High-toughness fused corundum wear-resistant coating and preparation method thereof

A technology of fused corundum and wear-resistant coatings, applied in the field of coatings, can solve the problems of inability to play a protective role, low toughness, easy to produce cracks, etc., to reduce thermal recession, improve heat resistance, and increase compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

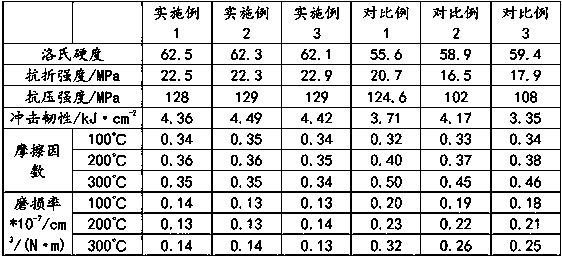

Examples

preparation example Construction

[0049] The preparation method of this wear-resistant coating comprises the steps:

[0050] Step S1, adding the fused corundum into the mixer according to its weight, and stirring at 300r / min for 2-3min;

[0051] Step S2, then add the weighed binder into the mixer, and continue to stir at 300r / min for 2-3min;

[0052] Step S3: Add additives and activated micropowder into the mixer, increase the stirring speed to 500r / min, stir for 4-5min, finally add silicon carbide, stir for 3-5min, after mixing evenly, add ethanol, stir at 600r / min for 2- 3min to obtain a wear-resistant coating.

Embodiment 1

[0054] A high-toughness fused corundum wear-resistant coating, made of the following raw materials in parts by weight: 30 parts of fused corundum, 5 parts of binder, 0.2 parts of auxiliary agent, 2 parts of activated micropowder, 1.6 parts of silicon carbide, and 7 parts of ethanol;

[0055] The wear-resistant coating is made by the following steps:

[0056] Step S1, adding the fused corundum into the mixer according to its weight, and stirring at 300r / min for 2min;

[0057] Step S2, then add the weighed binder into the mixer, and continue to stir at 300r / min for 2min;

[0058] Step S3, add the auxiliary agent and activated micropowder into the mixer, increase the stirring speed to 500r / min, stir for 4min, finally add silicon carbide, stir for 3-5min, after mixing evenly, add ethanol, stir for 2min at 600r / min, to obtain Grinding paint.

Embodiment 2

[0060] A high-toughness fused corundum wear-resistant coating, made of the following raw materials in parts by weight: 35 parts of fused corundum, 6.5 parts of binder, 0.25 parts of auxiliary agent, 2.5 parts of activated micropowder, 1.8 parts of silicon carbide, and 8.5 parts of ethanol;

[0061] The wear-resistant coating is made by the following steps:

[0062] Step S1, adding the fused corundum into the mixer according to its weight, and stirring at 300r / min for 2.5min;

[0063] Step S2, then add the weighed binder into the mixer, and continue to stir at 300r / min for 2.5min;

[0064] Step S3: Add additives and activated micropowder into the mixer, increase the stirring speed to 500r / min, stir for 4.5min, finally add silicon carbide, stir for 4min, after mixing evenly, add ethanol, stir for 2.5min at 600r / min, and obtain Grinding paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com