Non-asbestos wet-rolled automobile drum type brake block and manufacturing method thereof

A brake pad, asbestos-free technology, applied in the field of drum brake pads, can solve problems such as environmental pollution and human health hazards, and achieve the effects of high carbon content, pollution avoidance, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

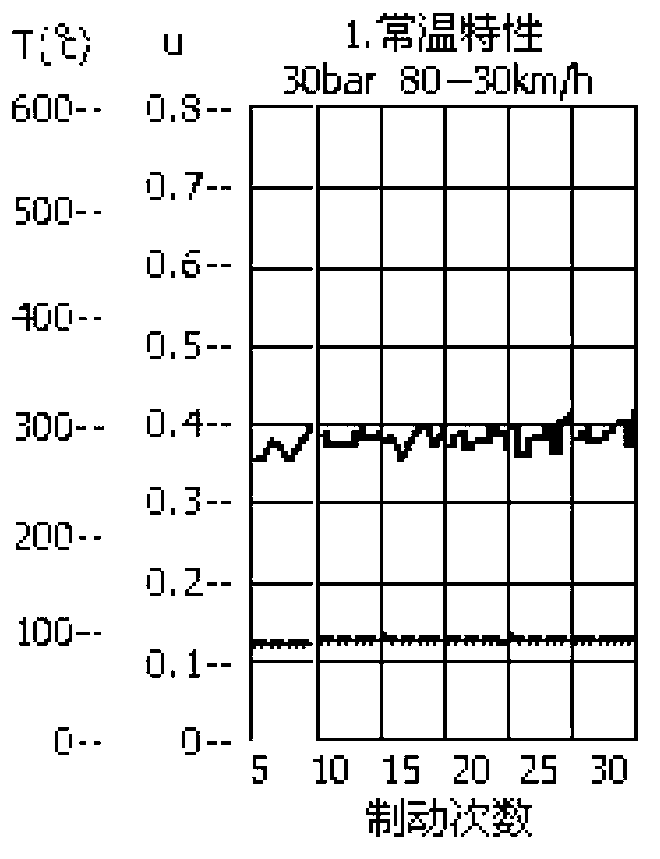

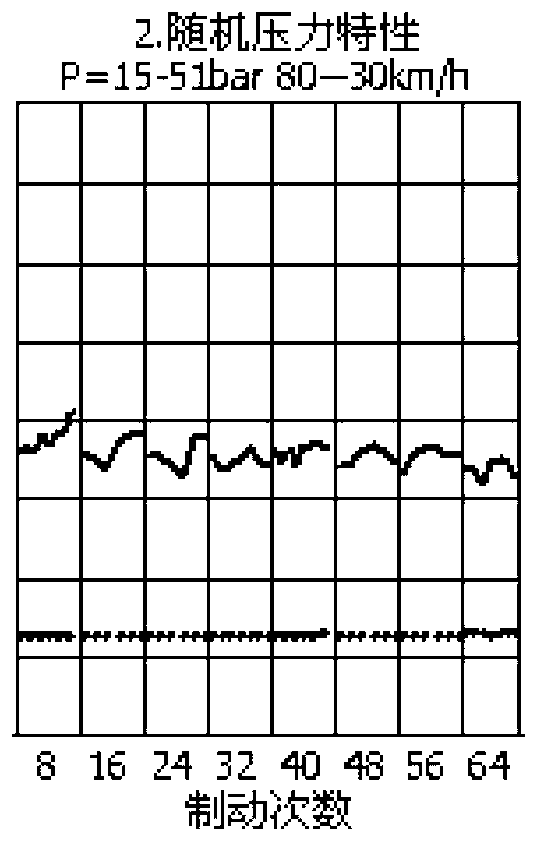

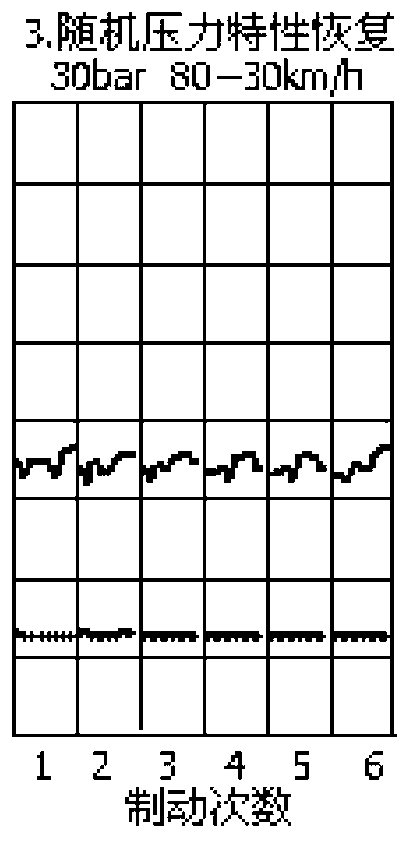

Image

Examples

Embodiment 1

[0038] Embodiment 1: A kind of method that adopts above-mentioned friction material to produce non-asbestos wet rolling automobile drum brake pad, it is characterized in that concrete steps are as follows:

[0039] (1) Prepare the following materials in parts by weight: 2 parts of aluminum silicate, 5 parts of zinc powder, 5 parts of barite powder, 8 parts of acicular wollastonite, 19 parts of synthetic graphite, 5 parts of cellulose fiber, and aramid fiber 2 parts, 45 parts of steel fiber, 4 parts of liquid resin, and 5 parts of phenolic resin; the liquid resin is NX-2034 solvent-free cashew nut shell oil liquid resin produced by Cardolite Company, and the synthetic graphite is selected from Shanghai Youai Metallurgical Materials Co., Ltd. Synthetic graphite model YUAI-MCH-01;

[0040] (2) Pour all the other materials in step (1) except the liquid resin into the rake mixer and pre-mix for 2-5 minutes at a stirring speed of 100-200r / min, then mix the liquid resin with 5-8L Gr...

Embodiment 2

[0045] Embodiment 2: A kind of method that adopts above-mentioned friction material to produce non-asbestos wet rolling automobile drum brake pad, it is characterized in that concrete steps are as follows:

[0046] (1) Prepare the following materials in parts by weight: 0.5 parts of aluminum silicate, 5 parts of zinc powder, 3 parts of barite powder, 6 parts of acicular wollastonite, 15 parts of synthetic graphite, 3 parts of cellulose fiber, and aramid fiber 1 part, 50 parts of steel fiber, 4 parts of liquid resin, and 4 parts of phenolic resin; the liquid resin is NX-2034 solvent-free cashew nut shell oil liquid resin produced by Cardolite Company, and the synthetic graphite is selected from Shanghai Youai Metallurgical Materials Co., Ltd. Synthetic graphite model YUAI-MCH-01;

[0047] (2) Pour all the other materials in step (1) except the liquid resin into the rake mixer and pre-mix for 2-5 minutes at a stirring speed of 100-200r / min, then mix the liquid resin with 5-8L G...

Embodiment 3

[0052] Embodiment three: a kind of method that adopts above-mentioned friction material to produce non-asbestos wet rolling automobile drum brake pad, it is characterized in that concrete steps are as follows:

[0053] (1) Prepare the following materials in parts by weight: 1.5 parts of aluminum silicate, 3 parts of zinc powder, 5 parts of barite powder, 7 parts of acicular wollastonite, 18 parts of synthetic graphite, 4 parts of cellulose fiber, and aramid fiber 1.5 parts, 55 parts of steel fiber, 5 parts of liquid resin, and 3 parts of phenolic resin; the liquid resin is NX-2034 solvent-free cashew nut shell oil liquid resin produced by Cardolite Company, and the synthetic graphite is selected from Shanghai Youai Metallurgical Materials Co., Ltd. Synthetic graphite model YUAI-MCH-01;

[0054] (2) Pour all the other materials in step (1) except the liquid resin into the rake mixer and pre-mix for 2-5 minutes at a stirring speed of 100-200r / min, then mix the liquid resin with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com