Automotive water-cooled disc brake

A water-cooled disc and brake technology, which is applied to the control of brake types, brake components, and coolant flow, can solve problems such as low heat dissipation capacity, reduced braking efficiency of ordinary disc brakes, and difficulty in fully exerting functions, etc., to achieve Improve heat dissipation, improve thermal stability and heat dissipation, and reduce thermal decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

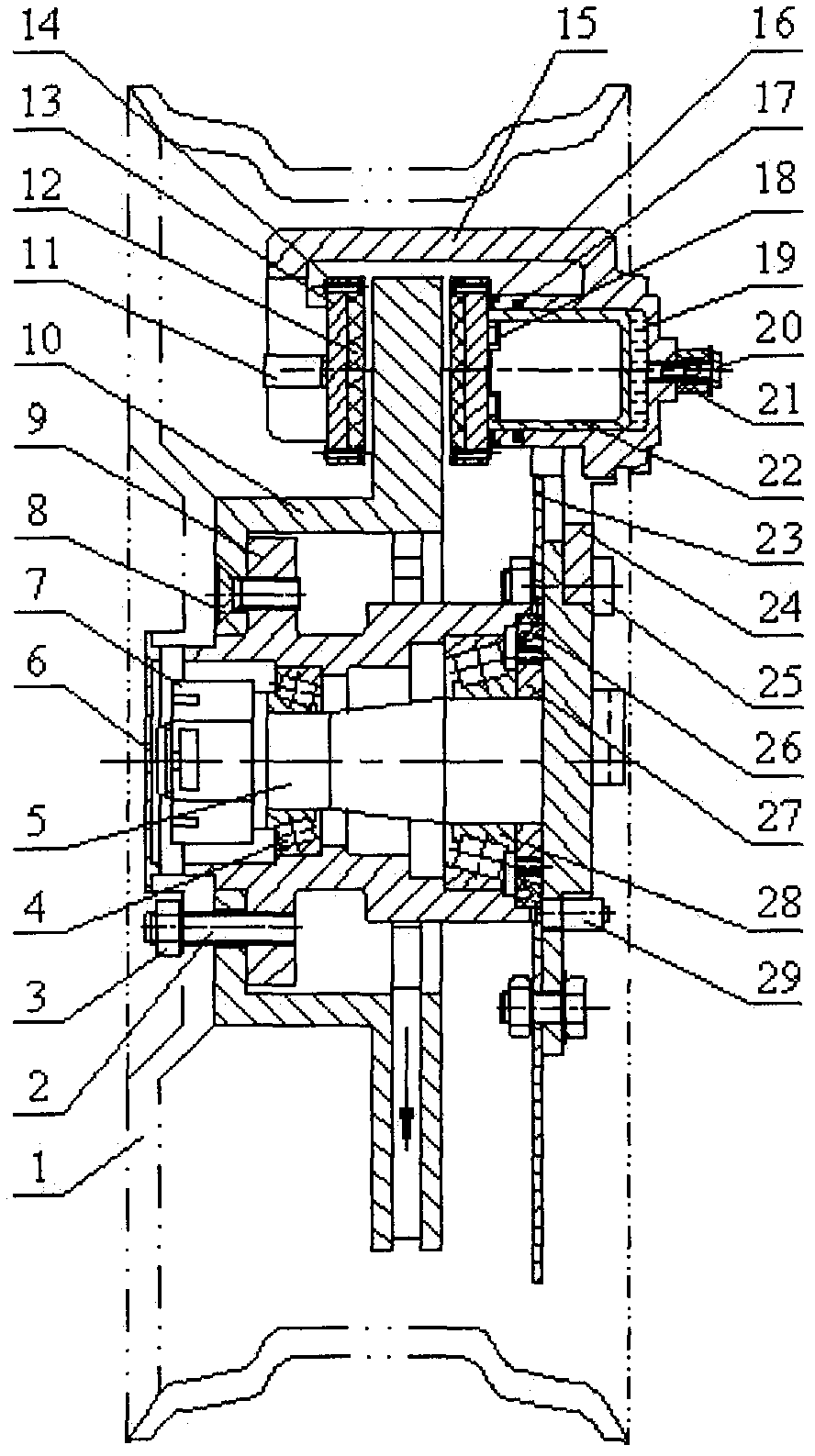

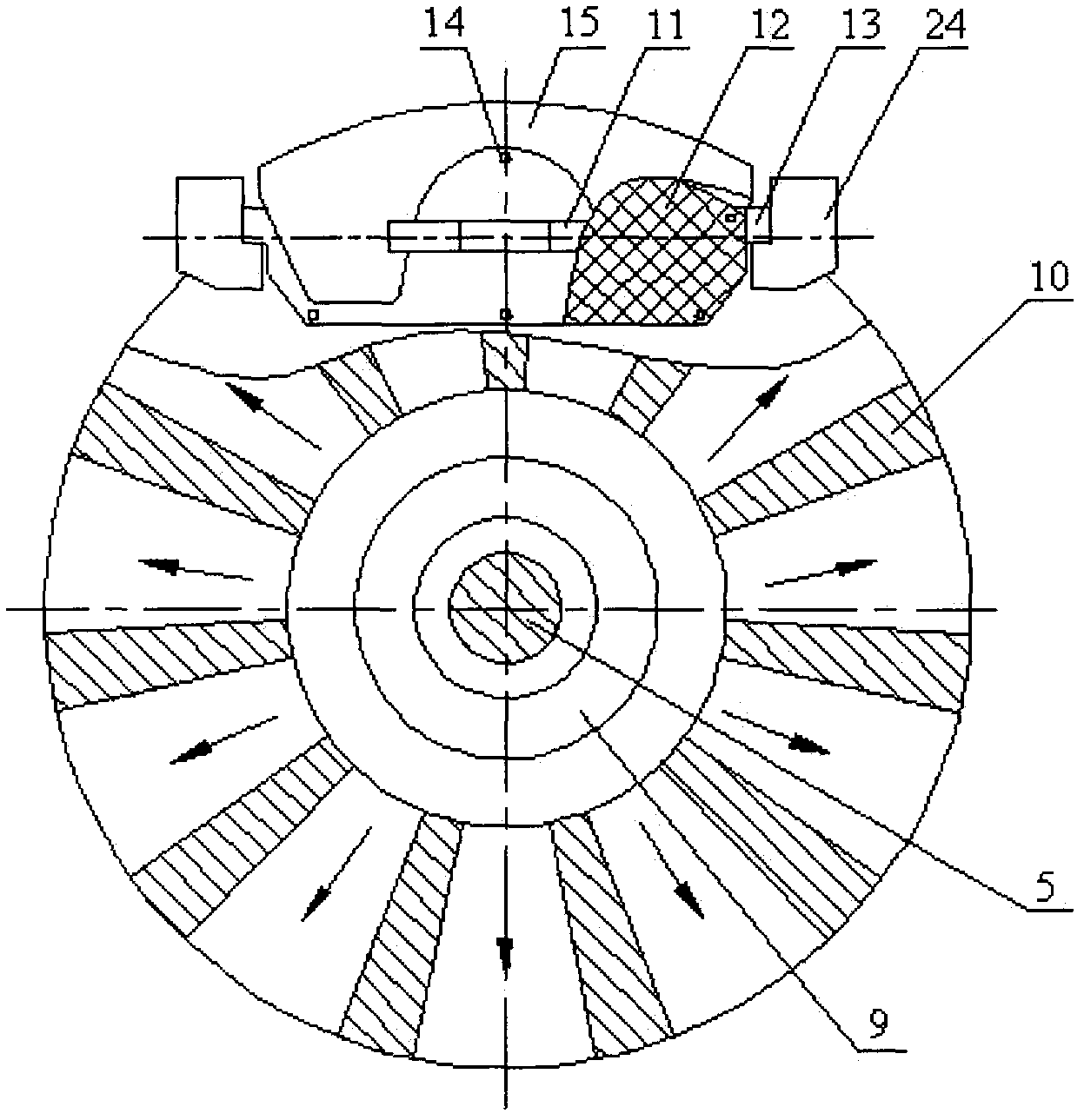

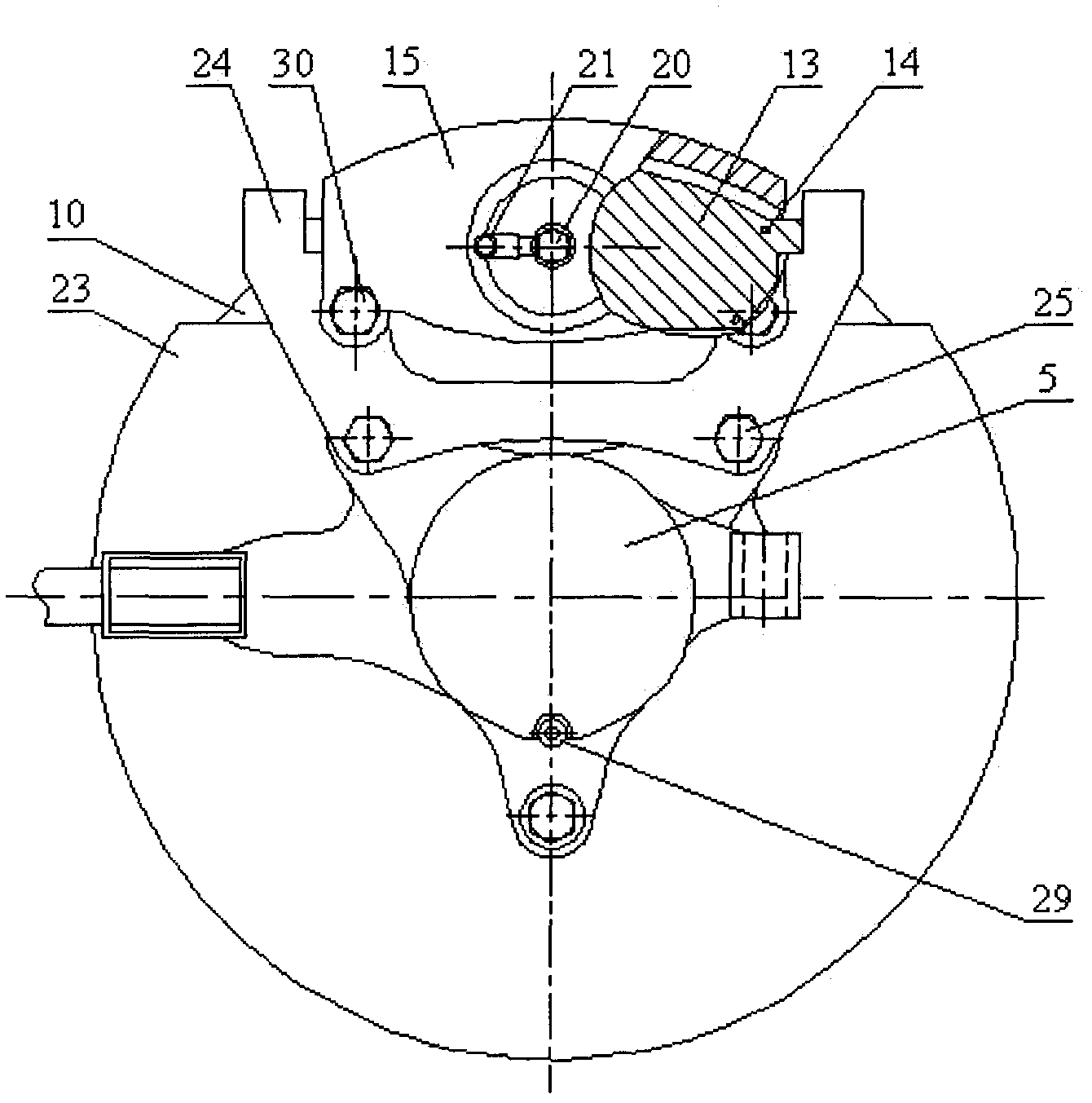

[0042] Automobile water-cooled disc brakes include water-cooled disc brakes and coolant circulation control systems, which replace ordinary disc brakes on automobiles, such as Figure 4-12 Shown.

[0043] Water-cooled disc brakes include outer circlip 11, brake pad friction plate 12, rivet 14, piston dust cover 16, piston seal 17, inner circlip 18, oil inlet bolt 20, oil inlet pipe 21, piston 22, brake Caliper frame 24, caliper frame bolt 25, brake caliper guide pin 30, brake pad water outlet pipe 31, brake pad cover 33, hollow brake pad bottom plate 34, outer brake disc 35, brake disc screw 36, outer Cooling disc 37, outer sealing spring 38, inner brake disc 39, inner cooling disc 40, tube-carrying brake caliper body 41, dust baffle 42, cooling disc bottom plate 43, cooling disc outlet pipe 44, spline tube 45, elastic block Ring 46, inner spline sleeve 47, water pipe joint 48, inner sealing spring 49, inner water channel diaphragm 50, outer water channel diaphragm 51, outer spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com