Patents

Literature

31results about How to "Avoid defects such as pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical titanium alloy artificial joint precise forging method

ActiveCN103659186ALow requirementsGood mechanical propertiesMetal-working apparatusProsthesisArtificial jointsSurface oxidation

The invention discloses a medical titanium alloy artificial joint precise forging method. According to the method, Ti6A17Nb alloy bar materials are fed and made into blanks first, the blanks are heated in a resistance furnace to 840-880DEG C, the heat of the blanks is preserved for 30-60 minutes, rod bending is conducted, sand blowing is conducted, surface defects are polished, and glass lubricant dip-coating is conducted; the blanks are heated in the resistance furnace to 900-960DEG C, the heat of the blanks is preserved for 30-60 minutes, in-die forging forming is conducted, edge cutting is connected on an edge cutting machine, sand blowing is conducted so as to remove surface oxidation layers, and surface defects are polished; the blanks are heated in the resistance furnace to 750-780DEG C, the heat is preserved for 30-60 minutes, polishing and sand blowing treatment are conducted, and finally Ti6A17Nb medical titanium alloy artificial joint forge piece finished products are obtained. According to the method, the processes of blank making and rod bending are further arranged before die forging, so that the material utilization rate is improved, and the production cost is greatly reduced; a rectification process is added after die forging, so that the size precision of forge pieces is improved, forging defects are reduced, and the product pass rate is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

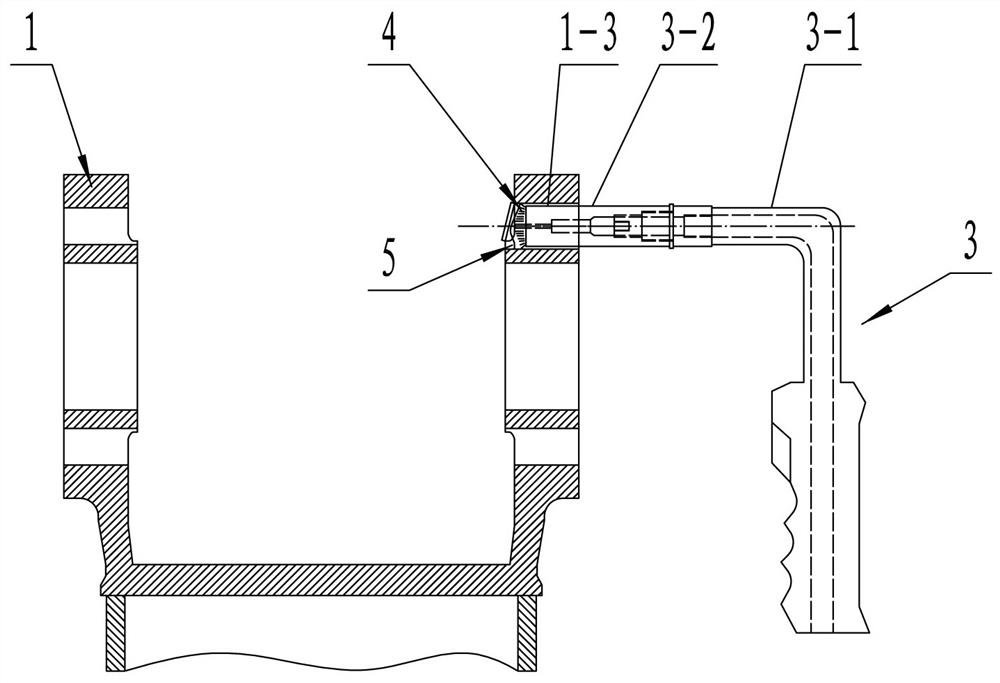

7-series high-strength aluminum alloy variable polarity plasma arc welding method

InactiveCN104607779AAvoid heat cracksAvoid defects such as poresArc welding apparatusPlasma welding apparatusWelding power supplyHeat balance

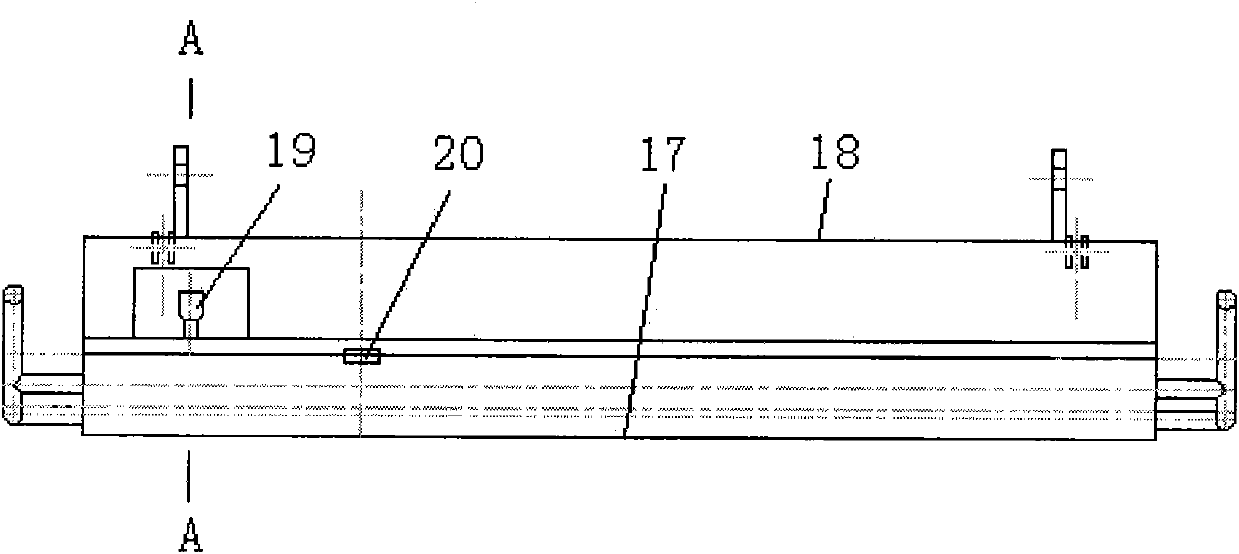

The invention relates to a 7-series high-strength aluminum alloy variable polarity plasma arc welding method. The method aims at solving the problem that in the prior art, the welding quality is poor. The vertical welding process is adopted, 7-series high-strength aluminum alloy workpieces are fixed through clamps after being vertically placed, a variable polarity plasma welding gun provided with an automatic wire feed device is horizontally placed on one side of the workpieces, the gun head of the welding gun right faces a welding seam between the two workpieces to conduct variable polarity plasma arc welding, the current selection range of the positive polarity and the negative polarity of the variable polarity plasma arc welding is between 190 A and 260 A, and the current selection range of the negative polarity is between 240 A and 300 A. A variable polarity plasma arc welding power supply serves as a power supply of the plasma welding gun. The 7-series high-strength aluminum alloy variable polarity plasma arc welding method has the advantages that 7-series high-strength aluminum alloy with a thickness ranging from 6 mm to 12 mm can be welded, it can be ensured that the reasonable temperature gradient section is formed between a liquid molten pool and solid metal in the welding process, the stable hole punching effect can be obtained, hole punching molten pool force and the heat balance can be ensured, the defects of welding hot cracks, pores and the like can be overcome, the appearance of the welding seam is uniform and neat, the welding deformation is small, and the welding efficiency is high.

Owner:INNER MONGOLIA UNIV OF TECH

Locomotive oil inlet casing sand core and manufacturing method thereof

InactiveCN106345973AReduce the numberReduce the mating surfaceFoundry mouldsFoundry coresGeomorphology3d printer

The invention discloses a locomotive oil inlet casing sand core which is composed of an upper sand core and a lower sand core. The invention also discloses a method for manufacturing the locomotive oil inlet casing sand core. The method comprises the following steps: A. converting a two-dimensional picture file of the locomotive oil inlet casing into a three-dimensional picture file; B. inverting the three-dimensional picture file into an integral-structure sand core picture file; C. carrying out modular cutting on the integral-structure sand core in the picture file obtained in the step B; D. making the section profile data of each sand core module into a distribution picture which can be recognized by a 3D printer; and E. printing the distribution picture through the 3D printer, thereby obtaining the sand core.

Owner:四川共享铸造有限公司

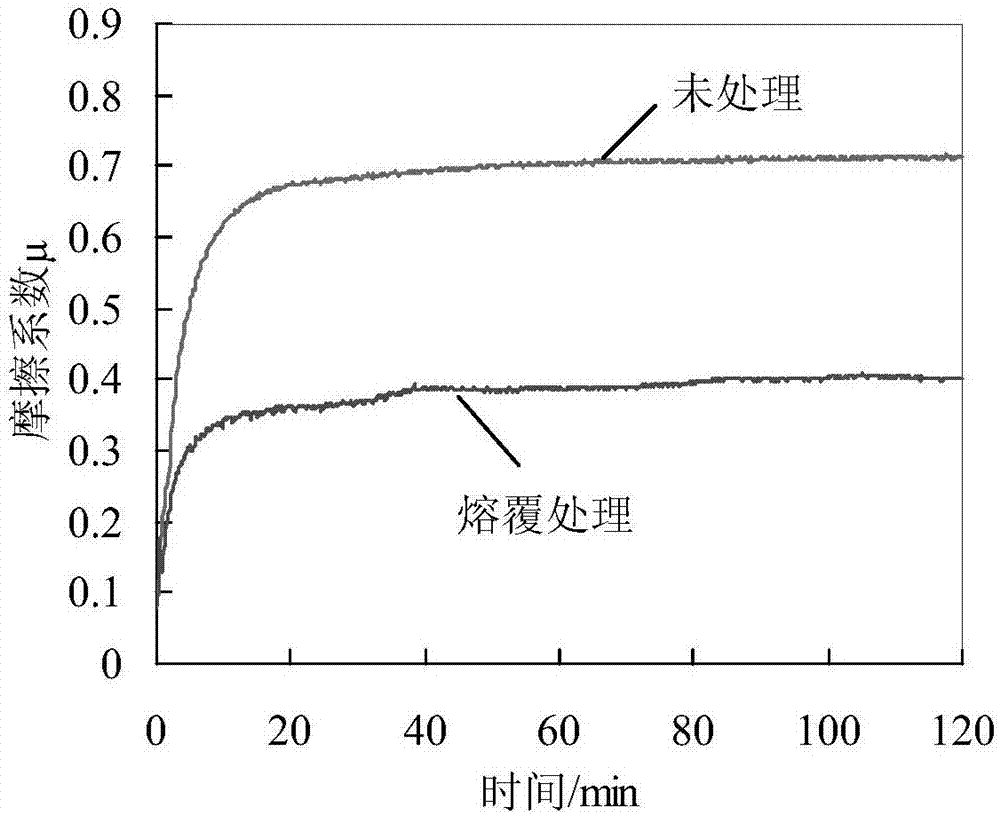

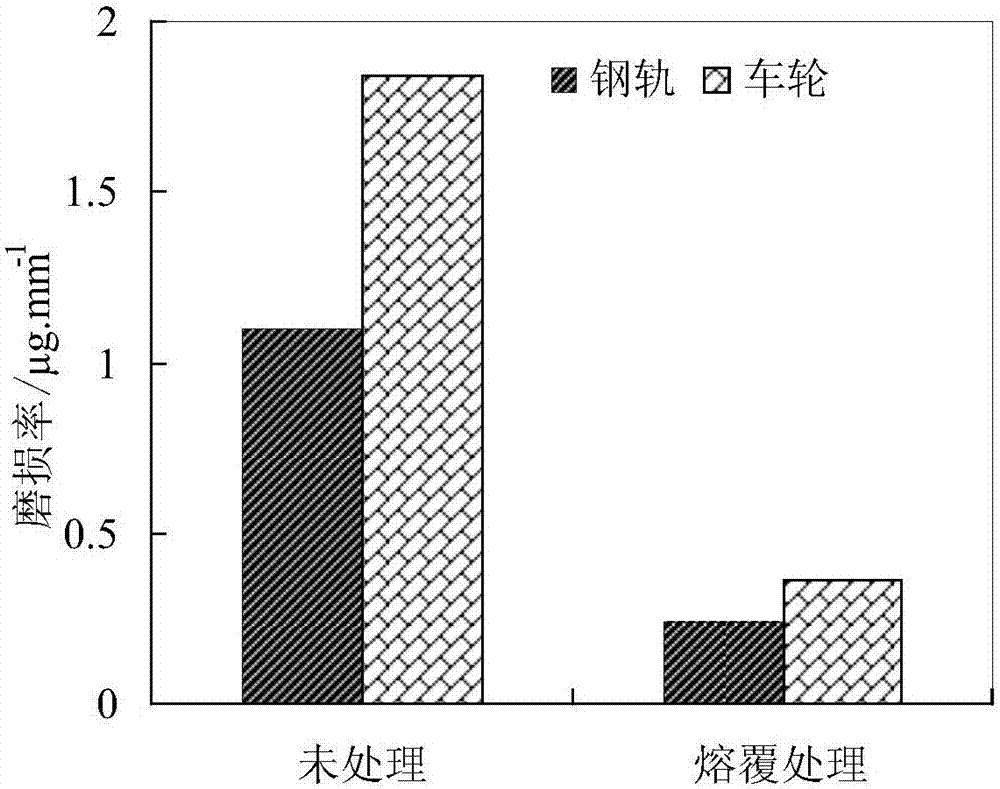

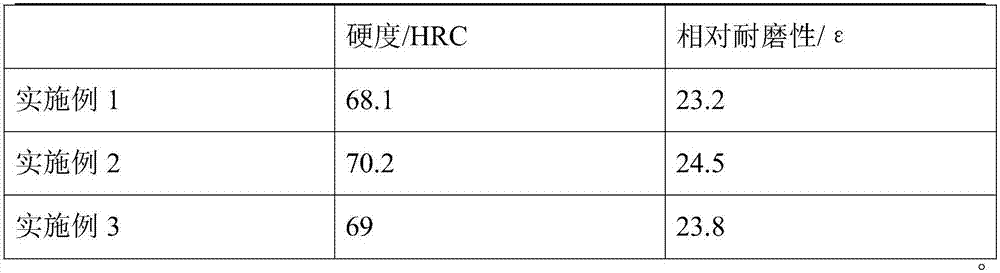

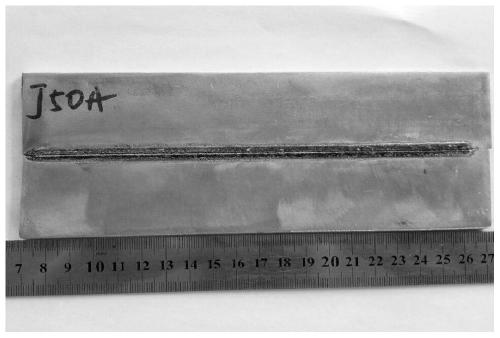

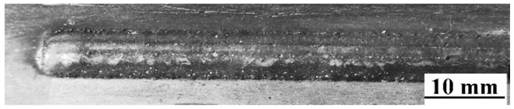

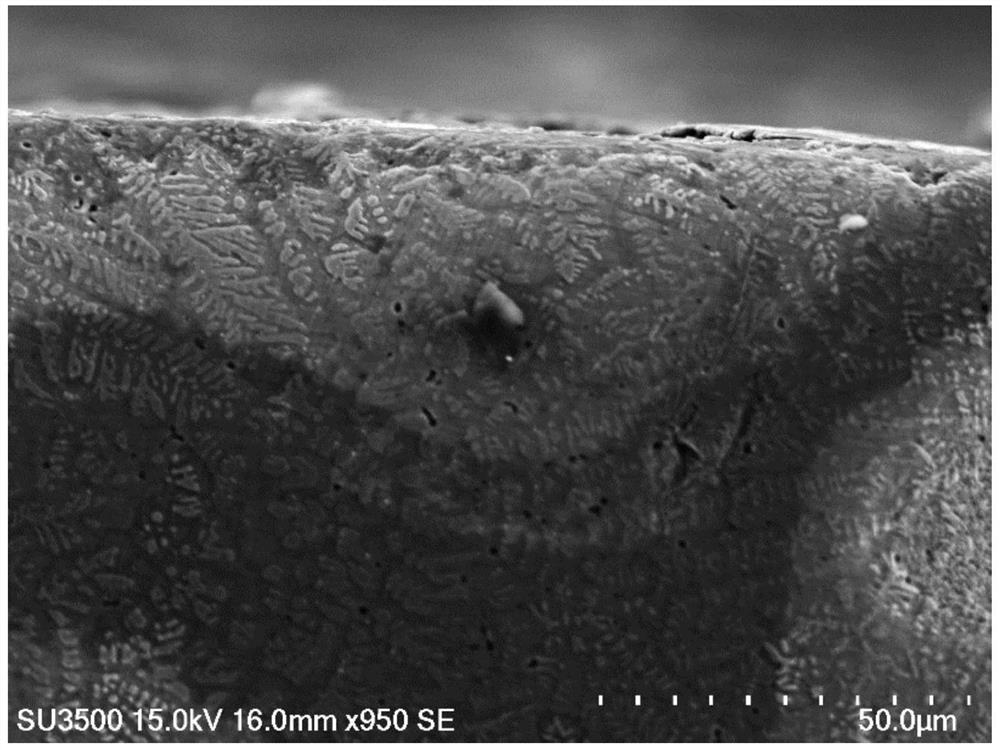

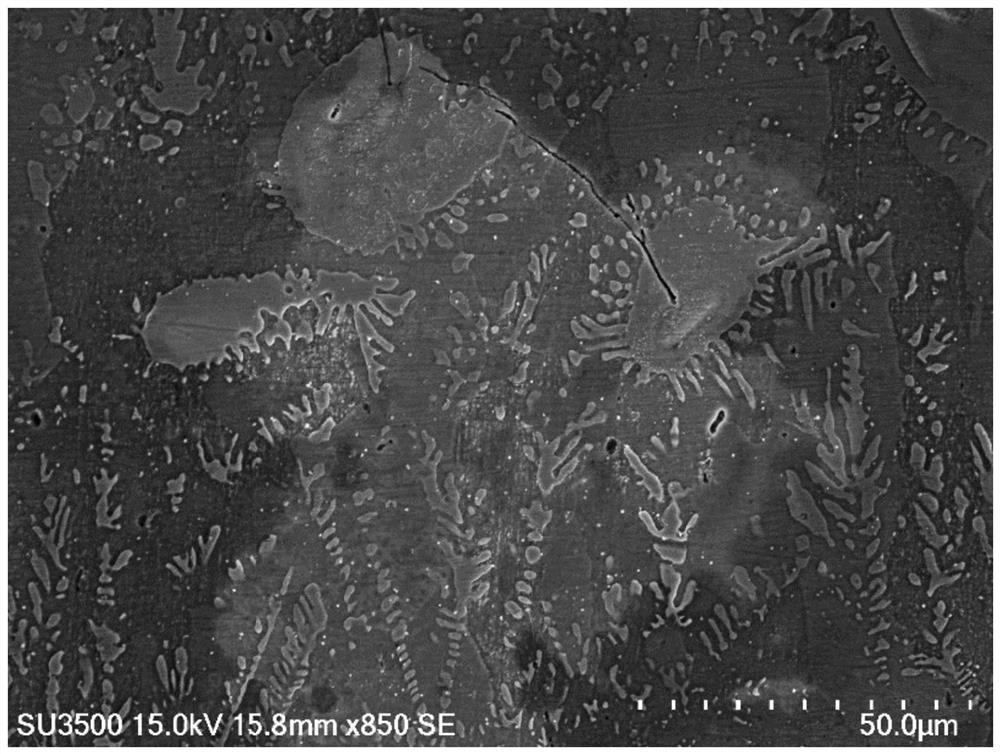

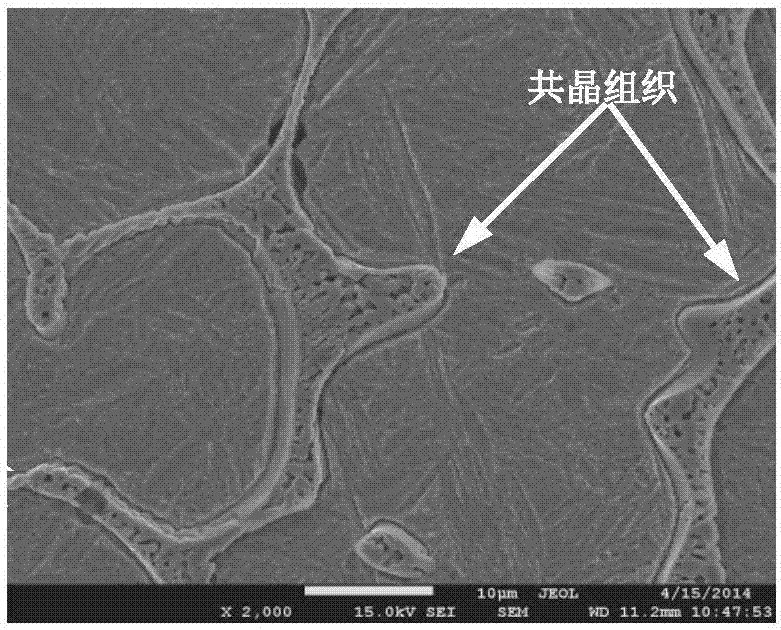

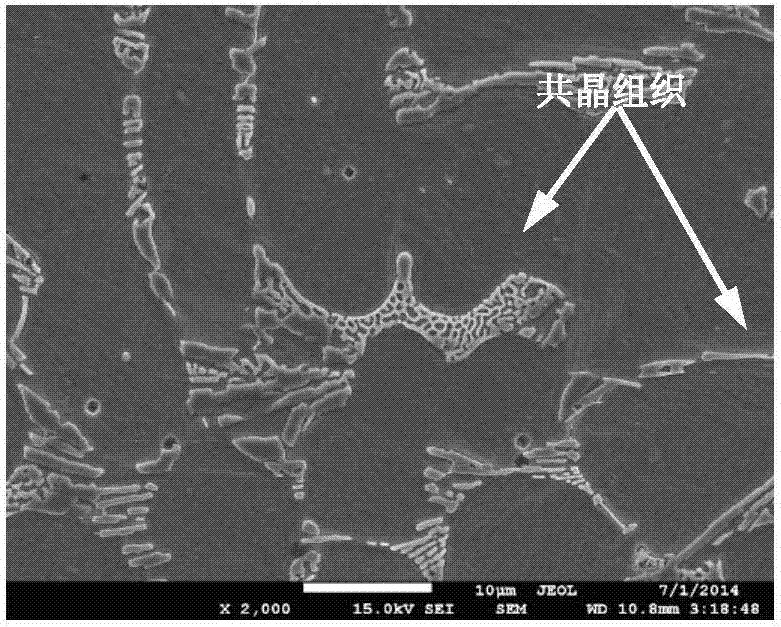

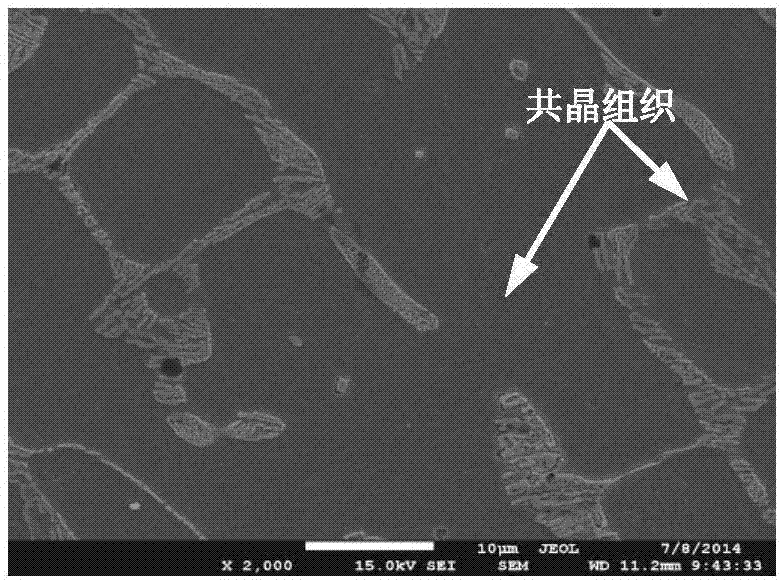

Method for improving heavy-load wheel rail wear-resistant performance by laser cladding cobalt alloy coating

InactiveCN107099793AImprove wear resistanceReduce coefficient of frictionMetallic material coating processesWear resistantRail wear

The invention discloses a method for reducing heavy-load wheel rim abrasion and steel rail lateral abrasion by a laser cladding cobalt alloy coating. The manufacturing method comprises the step of coating cobalt alloy powder onto the surface of a wheel rail by a laser, wherein the cobalt alloy powder is prepared from the following ingredients in percentage by weight: 1.1 percent of C, 1.0 percent of Si, 1.5 percent of Fe, 28.5 percent of Cr, 1.5 percent of Ni, 4.4 percent of W and the balance Co. A heavy load wheel rail treated by the method has the advantages of high wear-resistant performance, low friction coefficient and long service life.

Owner:SOUTHWEST JIAOTONG UNIV

Method for laser cladding of hard alloy coating on crown of turbine blade

ActiveCN103898502AQuality improvementSimple processMetallic material coating processesCarbide coatingTurbine blade

The invention belongs to the technology of metal surface treatment and particularly relates to an improved method for laser cladding of a hard alloy coating on a crown of a turbine blade. Laser three-dimensional forming equipment is adopted for carrying out laser cladding on the hard alloy coating. The method comprises the following steps: cleaning the blade; clamping the blade; vacuum-drying the hard alloy powder; and carrying out laser cladding. The invention provides an improved method for laser cladding of the hard alloy coating on the crown of the turbine blade, so that the steps are simplified, the operating time is shortened and the cladding efficiency is improved. Meanwhile, the defect of pores generated in the cladding process and the like is avoided, and the quality of the hard alloy coating is improved.

Owner:AECC AVIATION POWER CO LTD

Knar clay moulding sand prevented from adhering to casting and preparation method of knar clay moulding sand

InactiveCN105478655AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention discloses knar clay moulding sand prevented from adhering to a casting and a preparation method of the knar clay moulding sand. The knar clay moulding sand is prepared from, by weight, 24-38 parts of silica sand, 16-29 parts of high titanium slag, 14-22 parts of andalusite, 20-30 parts of basalt, 18-32 parts of kyanite, 10-15 parts of ceramic polishing slag, 9-16 parts of asbestos tailings, 45-55 parts of knar clay, 22-34 parts of salt gypsum, 12-18 parts of waste mortar, 10-15 parts of bone meal, 5-10 parts of aluminum dihydrogen phosphate and 300-400 parts of a modifying agent. The moulding sand prepared from the raw materials such as the knar clay, the silica sand, the ceramic polishing slag, the slat gypsum and the waste mortar according to a certain ratio has remarkable brittleness at the room temperature, and the sand is prevented from adhering to the surface of the casting, so that the casting with the high surface quality is obtained. Meanwhile, the moulding sand has high strength and thermal stability, can bear the action of various kinds of external force and high temperature and is suitable for production like steel casting, iron casting and casting of nonferrous alloy castings.

Owner:安徽创奇乐智能游乐设备有限公司

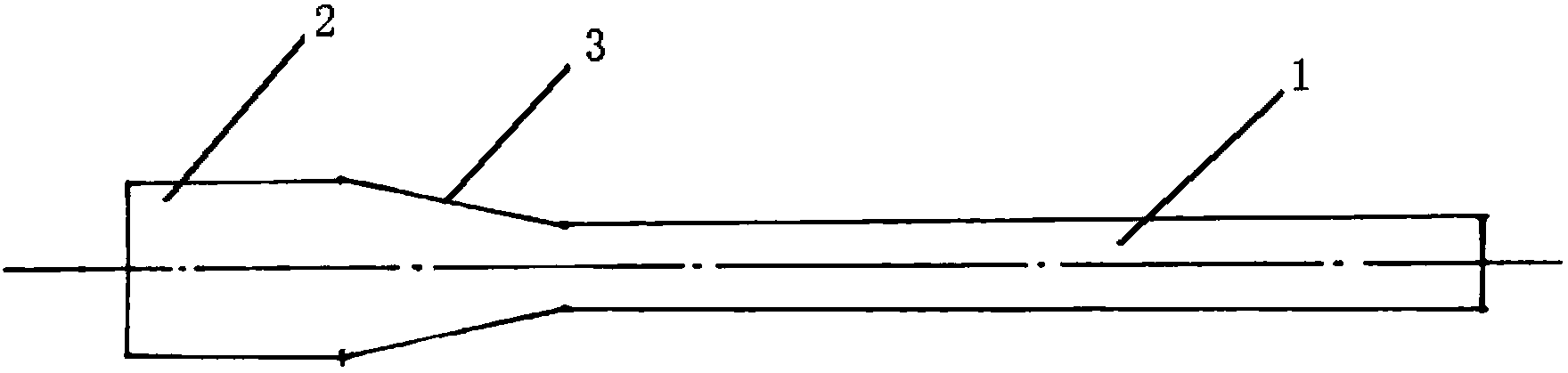

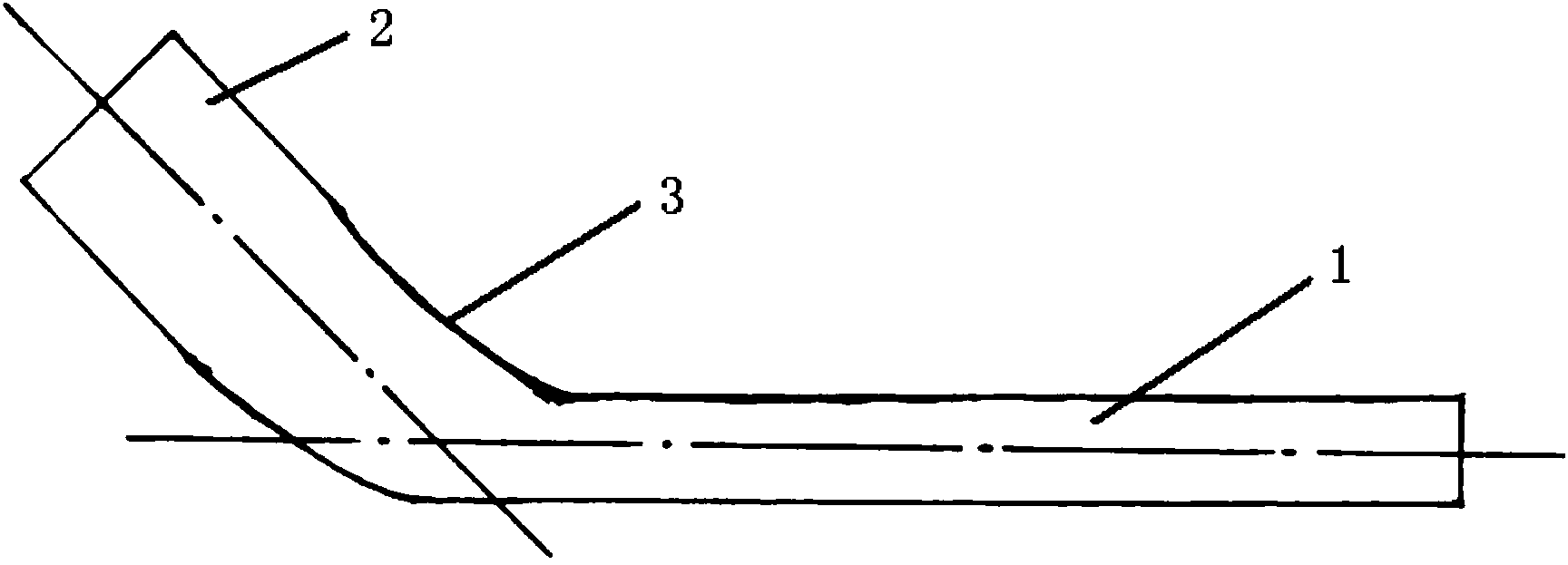

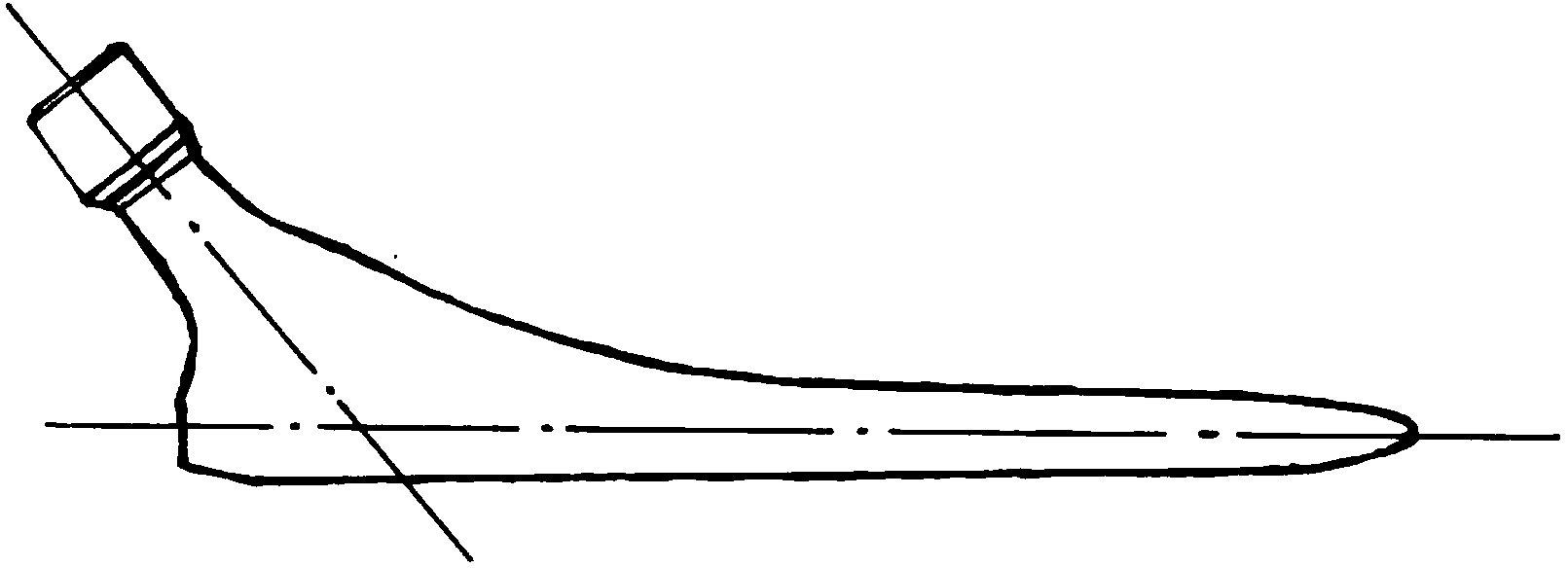

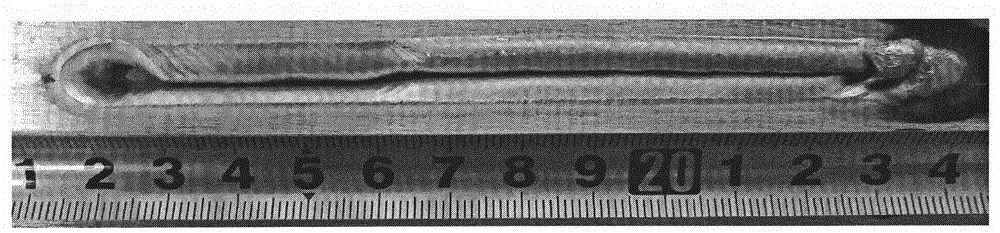

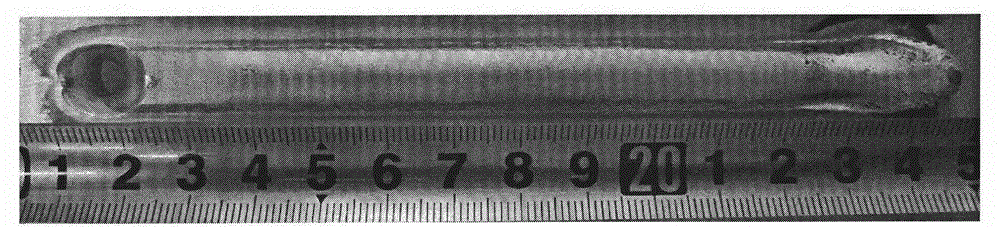

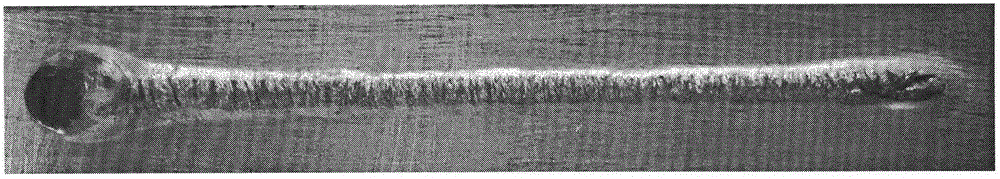

Silver-copper alloy wire for patch fuse wire and manufacturing method of silver-copper alloy wire

The invention belongs to the field of alloy wire manufacturing, and particularly discloses a silver-copper alloy wire for a patch fuse wire and a manufacturing method of the silver-copper alloy wire.The silver-copper alloy wire comprises elements of silver, indium, cerium, cobalt, palladium and copper; and the alloy wire with the elements has the advantages of being low in cost, stable in resistance value, high in tensile strength, small in change of resistance value along the temperature and the like. The manufacturing method comprises the following steps that firstly, the copper, the silver, the indium, the cerium and the cobalt are prepared according to the ratio, and smelting and processing are carried out to obtain a silver-copper alloy rod; then large-deformation processing is carried out on the prepared silver-copper alloy rod so as to prepare a silver-copper alloy crude wire; and finally, wire drawing is carried out on the prepared silver-copper alloy crude wire to prepare a finished product of the silver-copper alloy wire. According to the silver-copper alloy wire and the manufacturing method, the stability of the alloy component is ensured, and the defects of segregation, looseness, air holes and the like generated in the traditional pouring mode are avoided. The large-deformation processing enables grains in the alloy to be elongated, crushed and refined, so that the alloy components are uniformly dispersed, the resistance value of the patch fuse wire silver-copper alloy is more stable, and meanwhile, the strength is further improved.

Owner:JIAOZUO UNIV

High-hardness self-protection overlaying flux-cored wire and preparation method thereof

InactiveCN107052621AAvoid defects such as poresHigh hardnessWelding/cutting media/materialsSoldering mediaCarbon steelBoron nitride

The invention provides a high-hardness self-protection overlaying flux-cored wire and a preparation method of the high-hardness self-protection overlaying flux-cored wire. The high-hardness self-protection overlaying flux-cored wire comprises a low-carbon steel band and a flux core. The steel band is filled with the flux core. The flux core comprises, by mass, 70%-80% of high-carbon ferrochromium, 6%-10% of silicon-manganese alloy, 1%-2% of aluminum-magnesium alloy, 0.8%-3.6% of graphite, 0.5%-2% of boron nitride, 5%-13% of rutile and 2%-6% of fluorite. The flux core accounts for 45%-55% of the total weight of the flux-cored wire. The preparation method of the high-hardness self-protection overlaying flux-cored wire comprises the steps that (1) the low-carbon steel band is rolled into a U shape through a forming roller, and the flux core materials accounting for 45%-55% of the total weight of the flux-cored wire are added to a U-shaped groove; (2) the U-shaped groove is closed, the flux core is wrapped inside the U-shaped groove, a wire-drawing die is used for drawing and reducing pass by pass, finally the diameter of the flux-cored wire reaches 2.40-4.10 mm, and the finished product is obtained. The self-protection overlaying flux-cored wire has quite high hardness and quite high wear-proof performance.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Molding sand for high-density models and preparation method of molding sand

InactiveCN105983644AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresActivated sludgePolyethylene glycol

The invention discloses molding sand for high-density models and a preparation method of the molding sand. The molding sand is prepared from raw materials in parts by weight as follows: 27-39 parts of cement slurry, 64-76 parts of yellow loam, 22-34 parts of xonotlite, 15-25 parts of epistilbite, 41-53 parts of quartz sand, 16-24 parts of olivine, 8-16 parts of activated sludge dry powder, 5-10 parts of coke powder, 10-15 parts of yellow phosphorus ore, 14-22 parts of colloidal graphite powder, 5-10 parts of molybdenum disilicide, 7-11 parts of calcium lignosulphonate, 8-12 parts of polyethylene glycol and 450-550 parts of a modifier. The molding sand has the relatively high wet compressing strength and thermal tensile strength and further had the excellent gas permeability, liquidity and thermal resistance, the preparation technology of the molding sand is simple, the manufacturing cost is low, and the molding sand is suitable for large-scale popularization and application to the high-density models.

Owner:安徽创奇乐智能游乐设备有限公司

High-green-compression-strength green moulding sand for iron casting and preparation method of high-green-compression-strength green moulding sand

The invention discloses high-green-compression-strength green moulding sand for an iron casting and a preparation method of the high-green-compression-strength green moulding sand. The high-green-compression-strength green moulding sand is prepared from, by weight, 38-52 parts of imvite, 42-64 parts of natural manganese sand, 24-36 parts of silico-calcium slag, 19-31 parts of titanaugite, 16-24 parts of granite waste, 10-15 parts of asbestos wool, 15-25 parts of cancrinite, 11-19 parts of fibrolite, 8-12 parts of barium metaphosphate, 6-9 parts of polyester propylene glycol, 5-7 parts of polyamide polyamine epichlorohydrin resin and 510-570 parts of a modifying agent. By means of the raw materials such as the natural manganese sand, the silico-calcium slag, the asbestos wool, the barium metaphosphate, the polyester propylene glycol and the polyamide polyamine epichlorohydrin resin, on the basis of guaranteeing that the moulding sand has good breathability, the green compression strength of the moulding sand is remarkably improved, and box crushing, swelling and leaking can be effectively avoided. The prepared moulding sand has the advantages of being high in green compression strength, good in breathability and plasticity and the like, and is suitable for the iron casting and wide in application prospect.

Owner:安徽创奇乐智能游乐设备有限公司

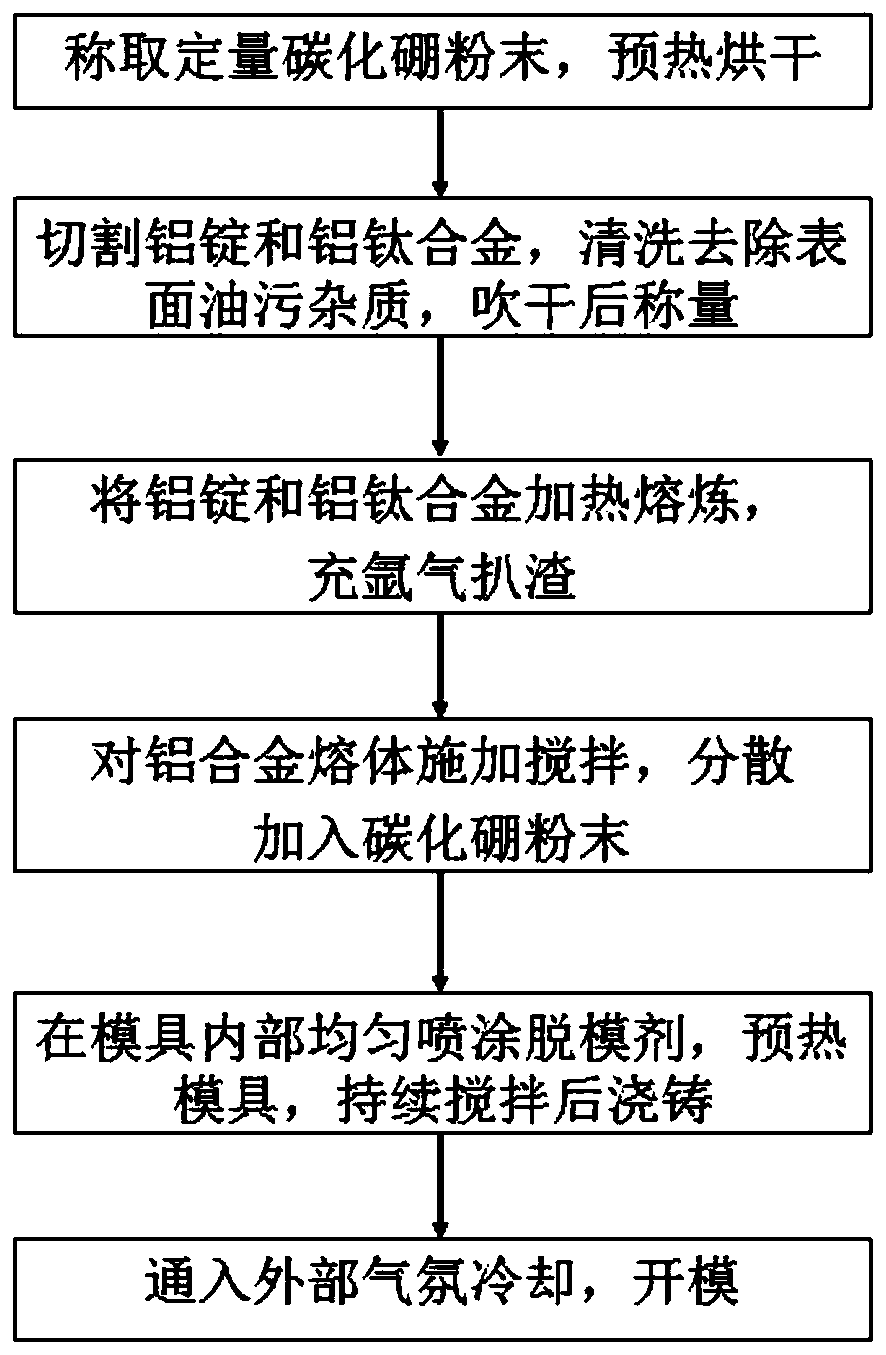

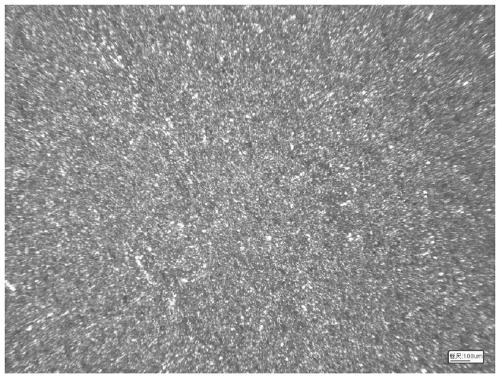

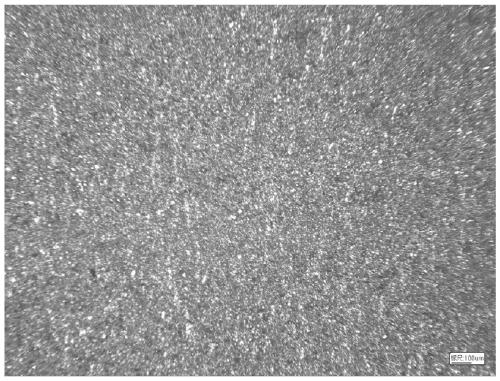

Casting preparation method of aluminum-based boron carbide composite material

The invention discloses a casting preparation method of an aluminum-based boron carbide composite material. The aluminum-based boron carbide composite material prepared by the method is uniform in boron carbide distribution, no agglomeration is caused, the plate surface is flat and free of impurities, the structure of the plate is compact, and no obvious casting defects such as pits, cracks and shrinkage holes exist. The preparation method is simple in process, simple in equipment, low in cost, and suitable for large-scale industrial production, and has development prospect.

Owner:SICHUAN JUNENG NUCLEAR TECH ENG

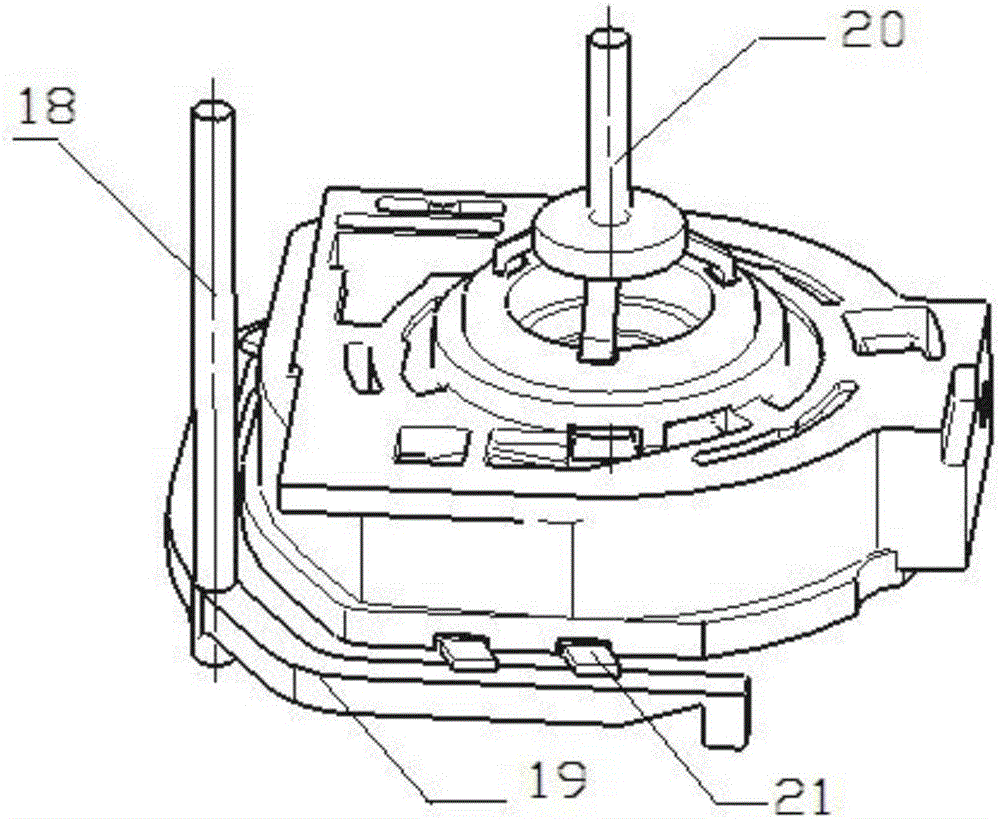

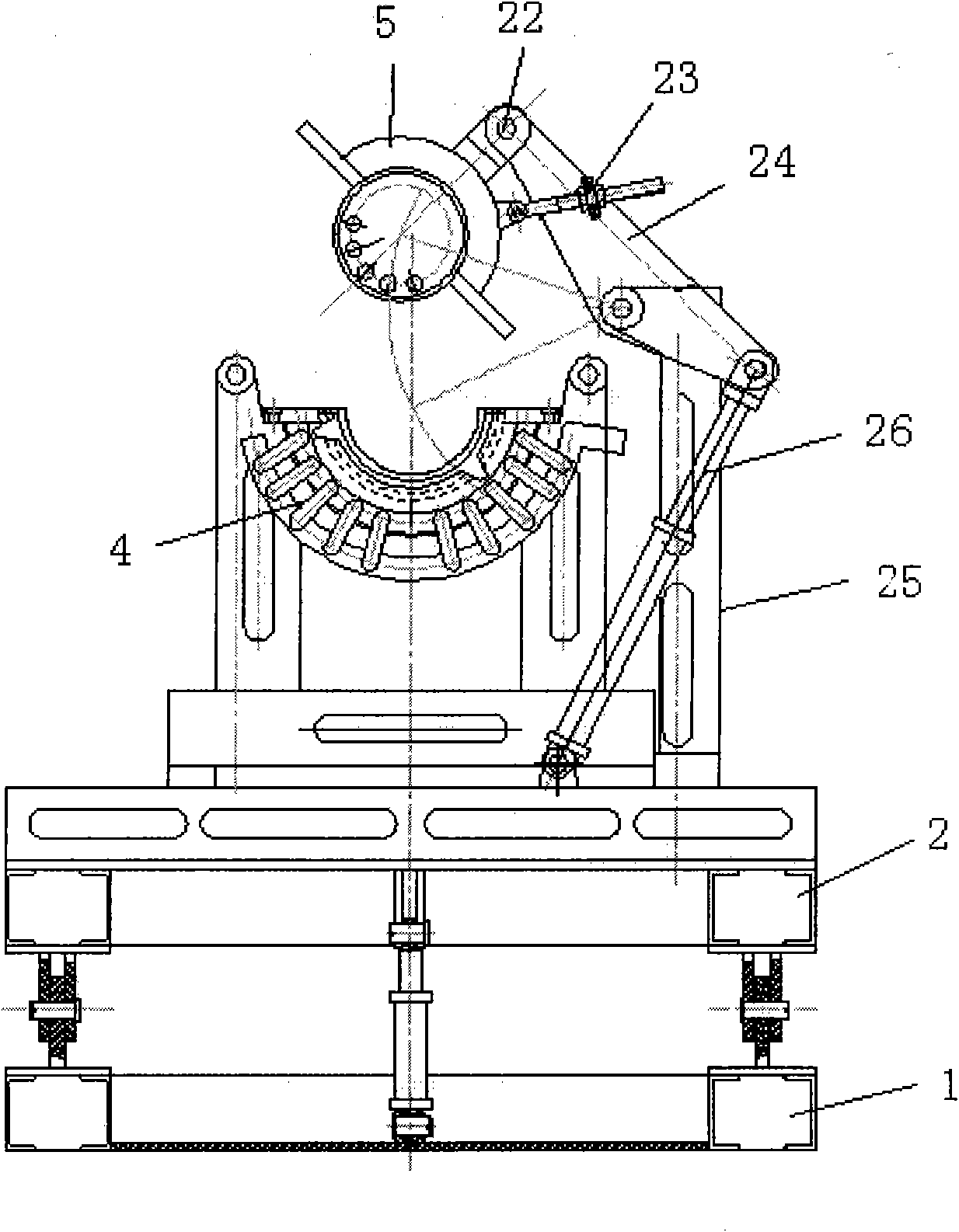

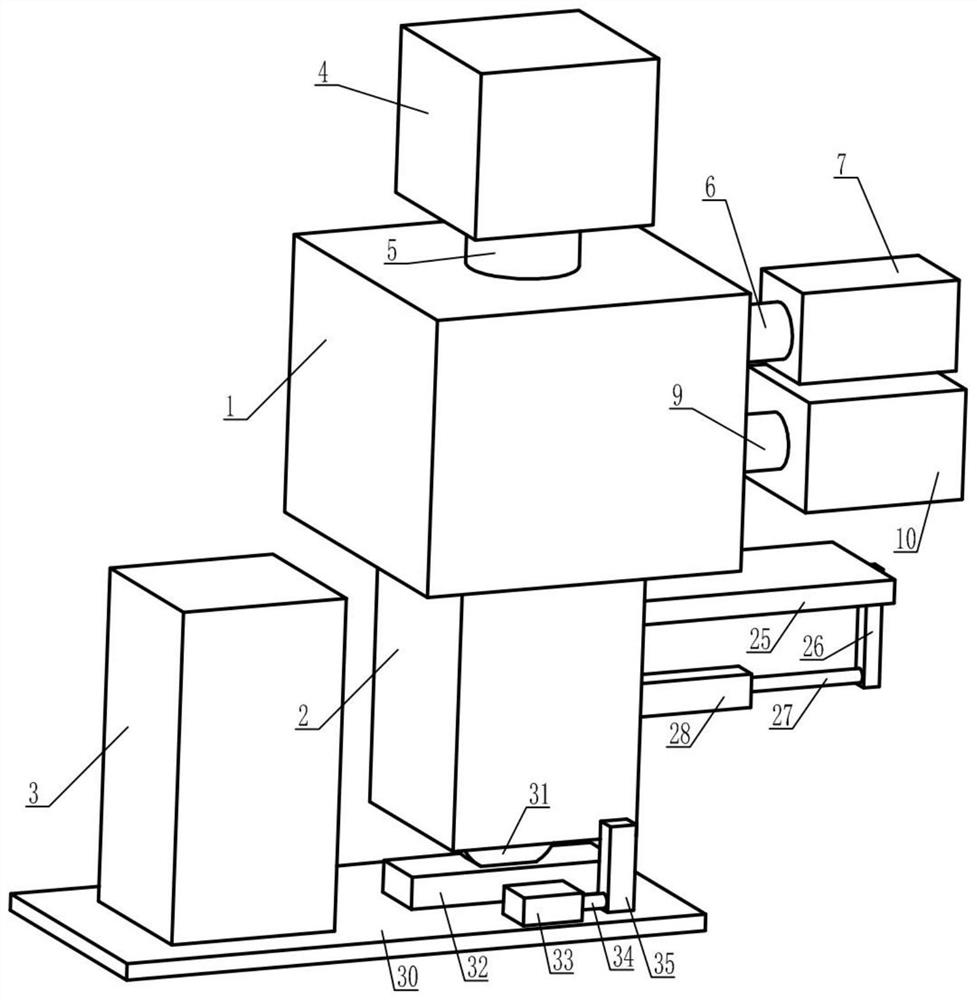

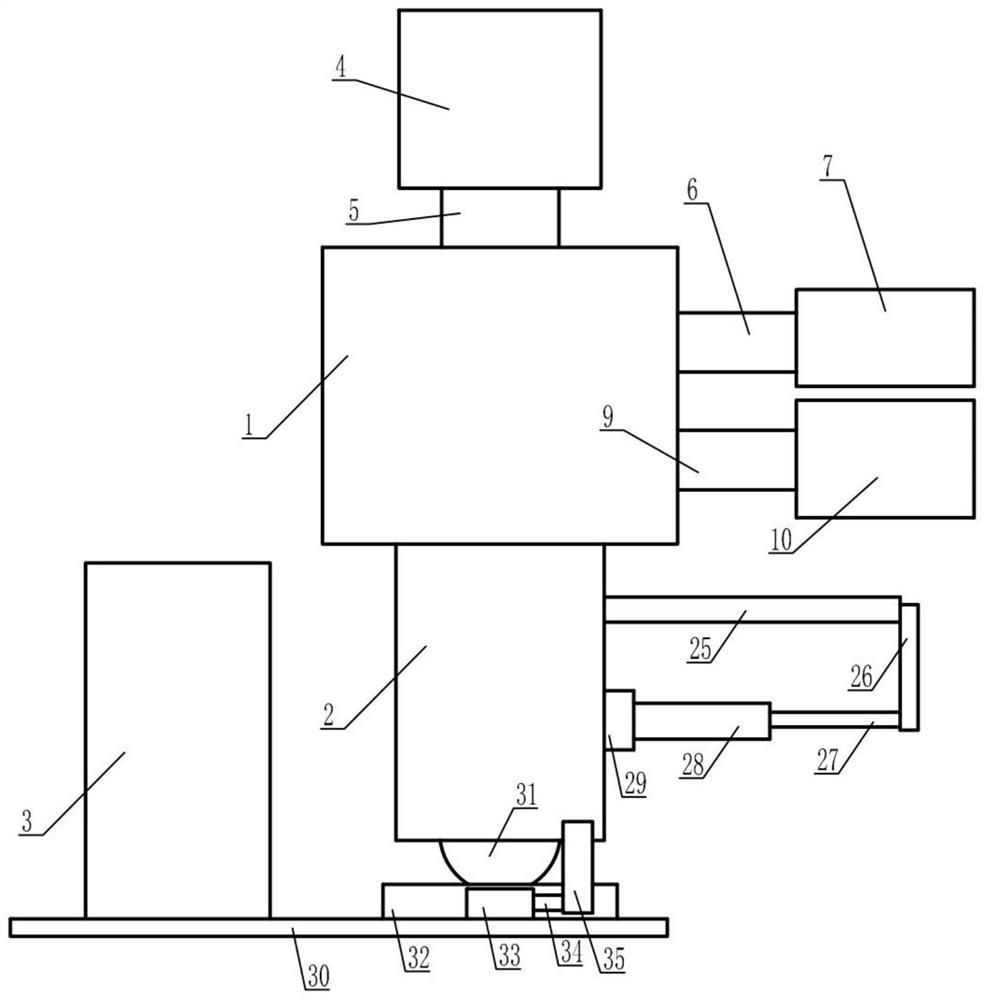

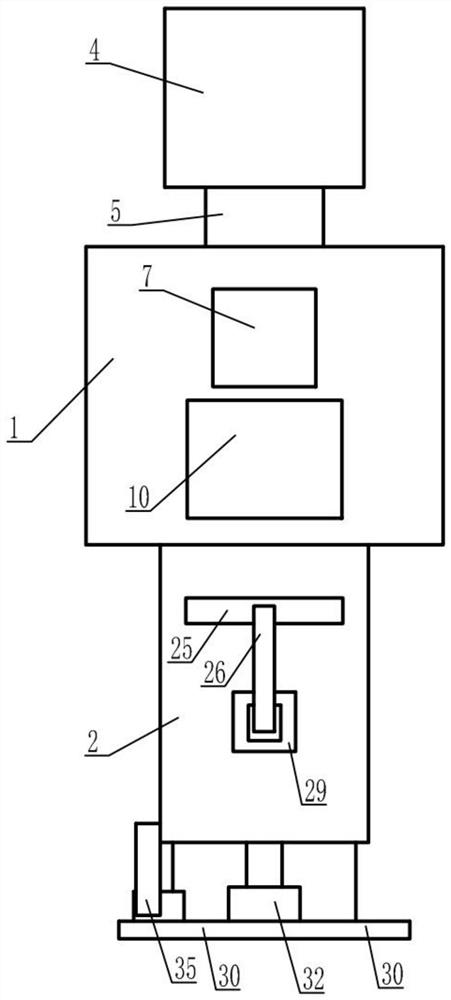

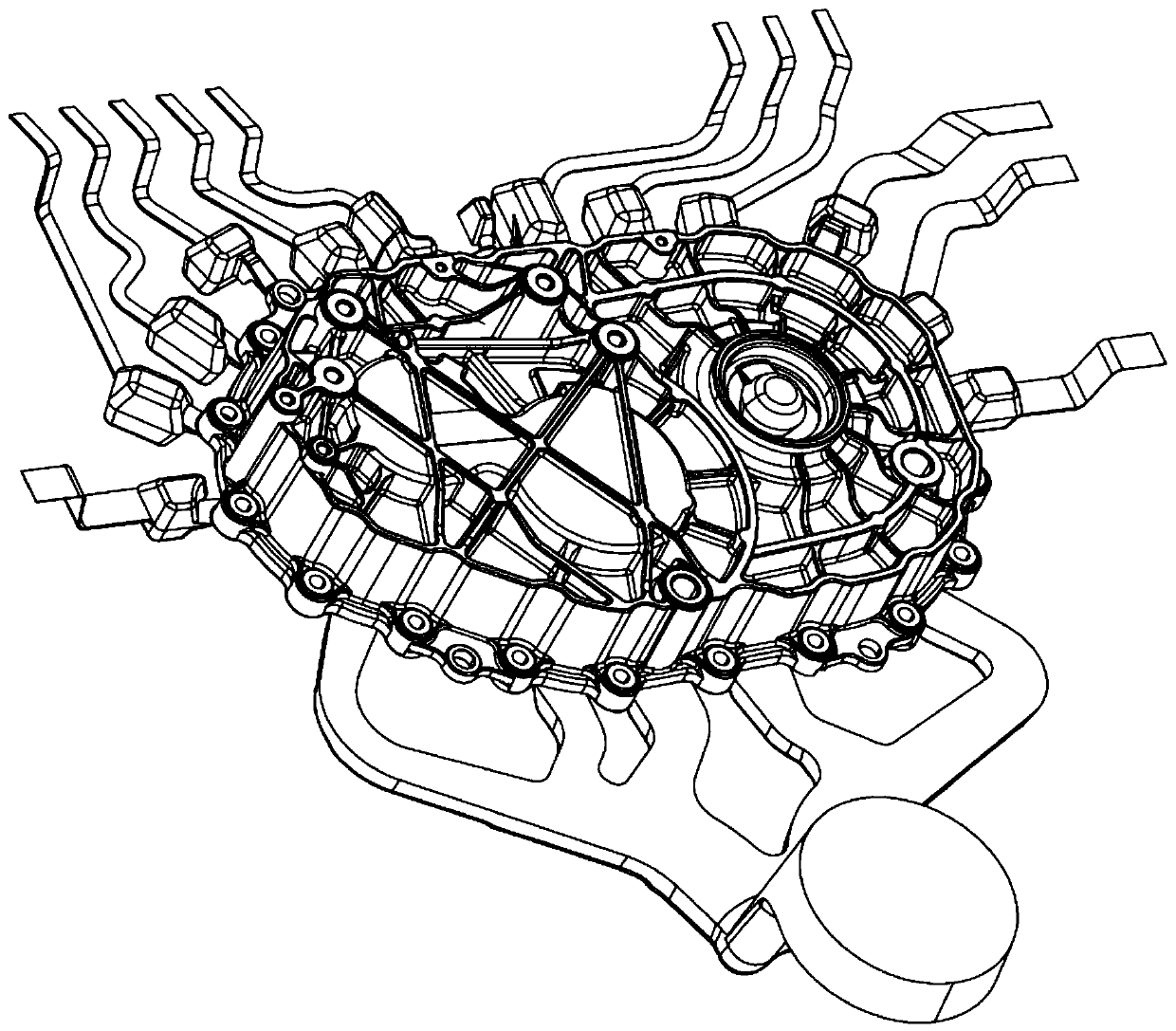

Casting mold for vortex-induced vibration suppression device

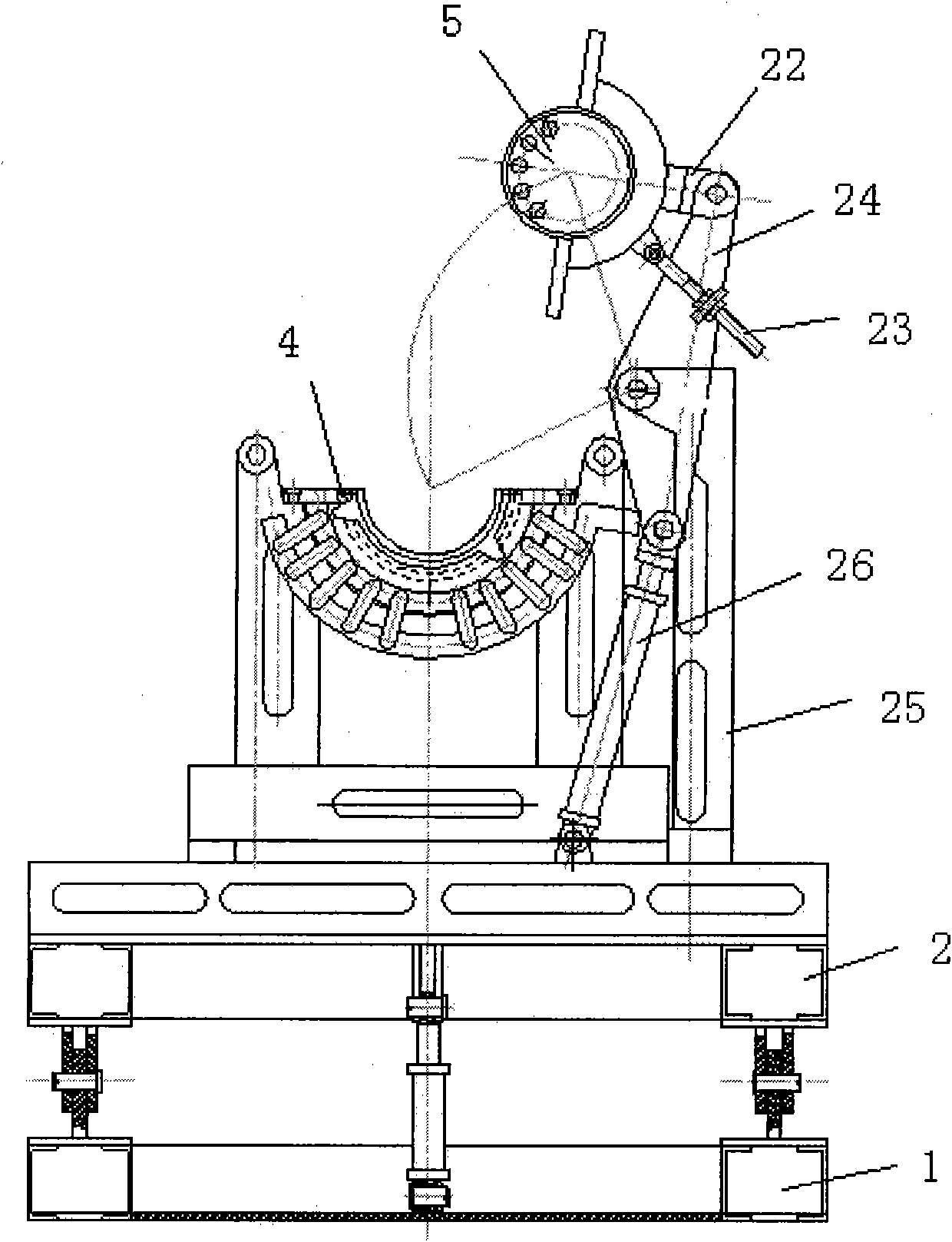

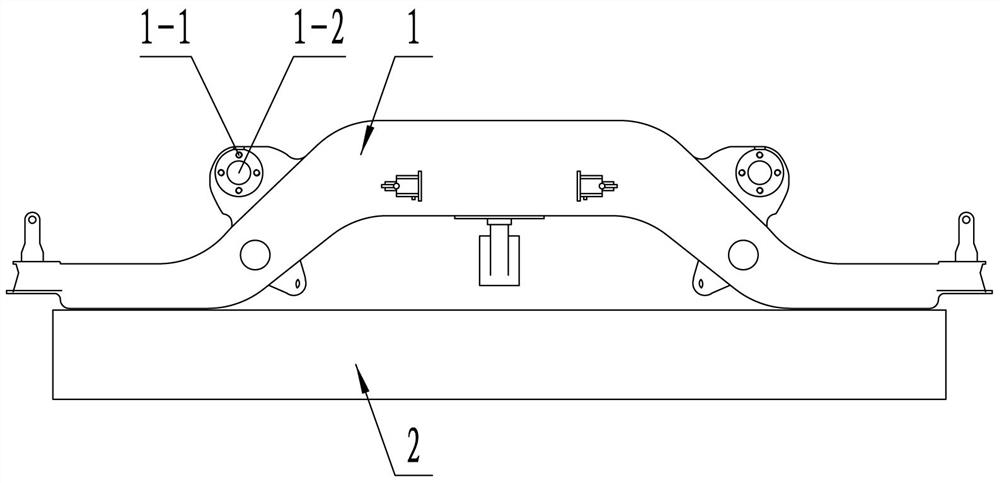

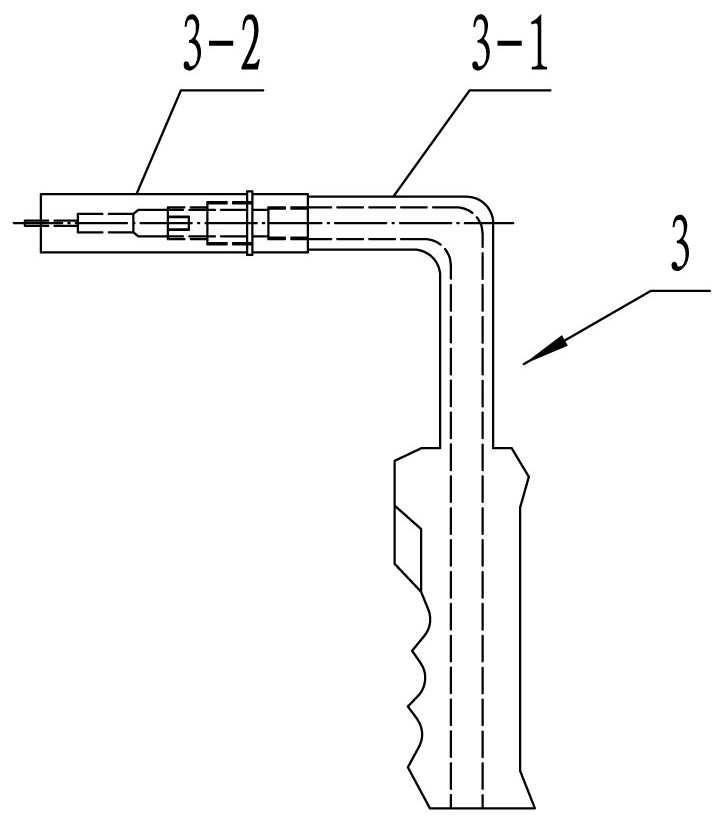

The invention discloses a casting mold for a vortex-induced vibration suppression device. The casting mold comprises an underframe, a rotating tilt stand, a female die, a female die support, a male die, a male die support, a rotating mechanism, a pressing mechanism, a hydraulic station, a heating device and the like; the female die consists of a semicircular female mold with a spiral groove, and a built-in heating coil; the male die consists of a semicircular male mold; the rotating mechanism and the pressing mechanism are hydraulic power mechanisms to control the rotating tilt stand and the male mold to oscillate; the mold comprises two sets to realize the casting of two parts of the vortex-induced vibration suppression device; and finally the two half parts are assembled into a molded product of the vortex-induced vibration suppression device.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Fusing agent for electrolytic aluminium anodic steel claws repairing

The invention relates to a fusing agent, particularly a fusing agent used at the fusion welding stage in the process of the electrolytic aluminium anodic steel claws repairing. which aims at providing a fusing agent capable of producing no air holes on the welding portion, increasing melting speed and reducing energy consumption. The following technical scheme is adopted: the fusing agent applied to electrolytic aluminium anodic steel claws repairing is composed of A12O3, CaF2and CaO. Compared with the prior technology, the fusing agent for electrolytic aluminium anodic steel claws repairing has the advantages in that: (1), the fusing agent floats in a metal pool and isolates outside air so as to avoid producing defects such as shrinkages, air holes and the like (2), the fusing point is decreased, fusing speed is increased and the energy consumption is reduced.

Owner:饶云福

High-strength and high-temperature-resistance molding sand and preparation method thereof

InactiveCN105478654AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresBrickCalcium formate

The invention discloses high-strength and high-temperature-resistance molding sand and a preparation method thereof. The high-strength and high-temperature-resistance molding sand is prepared by the following raw materials in parts by weight: 14-22 of allophane, 24-38 of attapulgite, 12-18 of obsidian, 10-15 of baddeleyite, 8-14 of waste brick chips, 5-10 of refining slag, 16-24 of emery, 9-16 of glauconite, 7-11 of calcium formate, 5-10 of nanometer magnesium titanate, 4-7 of polyethylenimine, and 270-330 of modifying agents. The molding sand, prepared with allophane, obsidian, baddeleyite, waste brick chips, refining slag, emery and the like as main raw materials, is better in thermal stability and higher in refractoriness, and is added with calcium formate, nanometer magnesium titanate, polyethylenimine and the like to improve the green compression strength and the wet tensile strength. The prepared molding sand is excellent in breathability, fluidity, strength, collapsibility and high-temperature resistance; and a casting produced by the molding sand is smooth in surface and low in rejection rate.

Owner:安徽创奇乐智能游乐设备有限公司

High-fluidity clay green molding sand used for steel casting and preparation method thereof

InactiveCN105562583AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresAdditive ingredientPhosphate

The invention discloses high-fluidity clay green molding sand used for a steel casting and a preparation method thereof. The high-fluidity clay green molding sand is made from, by weight, 25-40 parts of zircon sand, 18-32 parts of chromite residues, 11-19 parts of petrol coke powder, 14-26 parts of rectorite, 5-10 parts of waste molasses, 15-25 parts of vermiculite, 33-47 parts of nacrite, 9-18 parts of white onxy, 5-10 parts of spinel, 7-11 parts of ultra-fine aluminum silicate, 5-10 parts of tricalcium phosphate and 320-380 parts of improver. According to the high-fluidity clay green molding sand used for the steel casting and the preparation method thereof, the zircon sand and the nacrite are adopted as the main ingredients, and the chromite residues, the petrol coke powder, the rectorite, the white onxy, the spinel and other raw materials are added, so that the prepared clay green molding sand is made to have excellent fluidity; sand grains can easily move towards one another under the action of external force or gravity; the high-fluidity clay green molding sand further has good plasticity, gas permeability, collapsibility and heat stability.

Owner:安徽创奇乐智能游乐设备有限公司

Method for repairing transverse threaded holes of bogie of passenger train

ActiveCN112846635AImprove repair efficiencyHigh precisionVehicle dissasembly recoveryBogieShielding gas

The invention discloses a method for repairing transverse threaded holes of a bogie of a passenger train, and relates to the technical field of rail transit equipment repairing. The method comprises the steps of 1, detecting, 2 broaching, 3 blocking the holes, 4 drilling bottom holes, 5 tapping and 6 inspecting. In the step 1, the bogie is placed on a maintenance platform, the threaded holes in the bogie are transversely arranged, and whether each threaded hole is damaged or not is detected; in the step 2, a universal radial drill is used for broaching the damaged threaded holes; in the step 3, the damaged threaded holes are subjected to plugging welding through a special welding gun, the center line of a protective sleeve of the special welding gun is kept parallel to the center line of each expansion hole in the plugging welding process, and a welding bead is covered with protective gas; in the step 4, a corresponding drilling positioning tool is selected and installed according to the positions of the damaged threaded holes, and the universal radial drill is used for drilling the bottom holes in hole blocking parts; and in the step 5, a universal tapping machine installed on a trolley is used for tapping the bottom holes. According to the method, the problems that existing railway carriage bogie threaded hole repairing is low in efficiency, low in precision, high in reworking frequency and low in one-time repairing success rate are solved.

Owner:柳州机车车辆有限公司

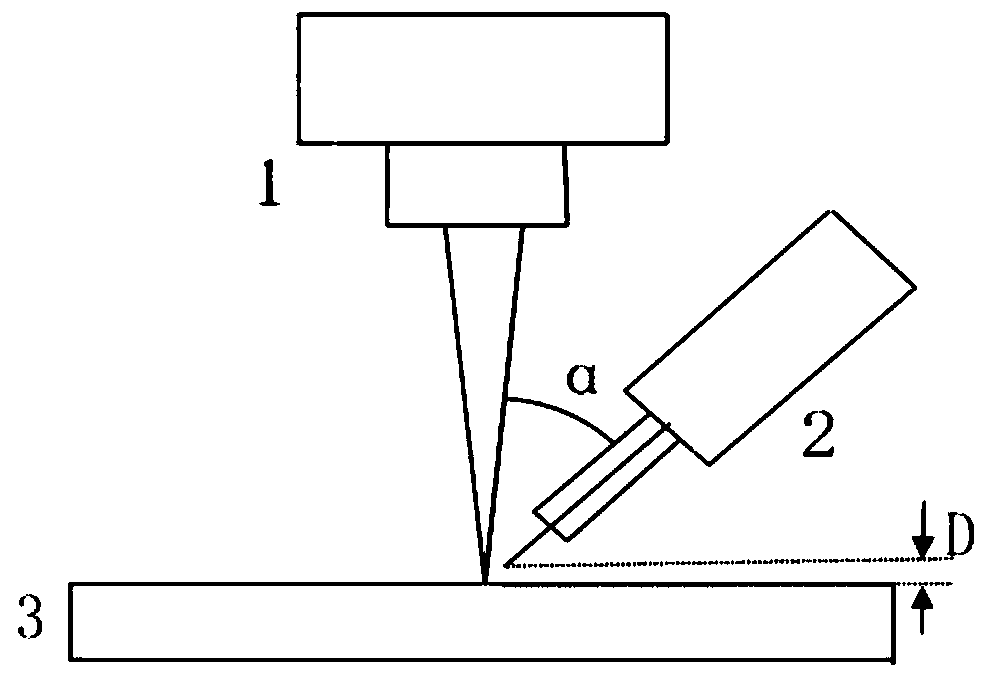

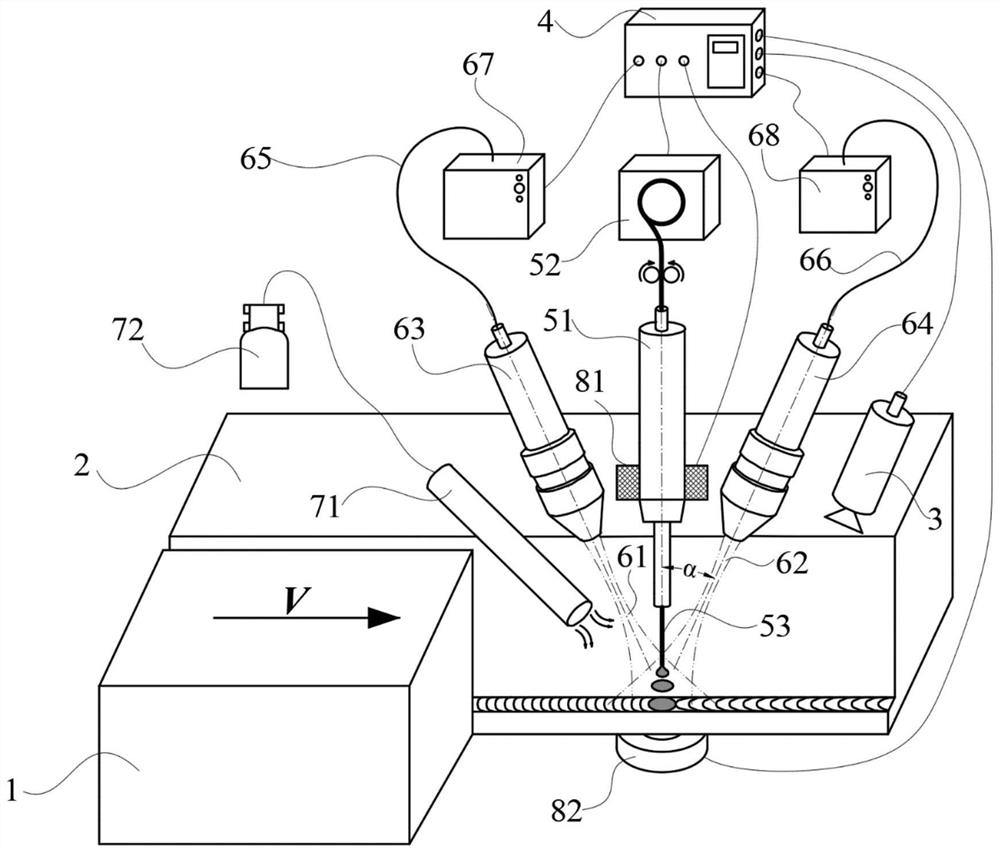

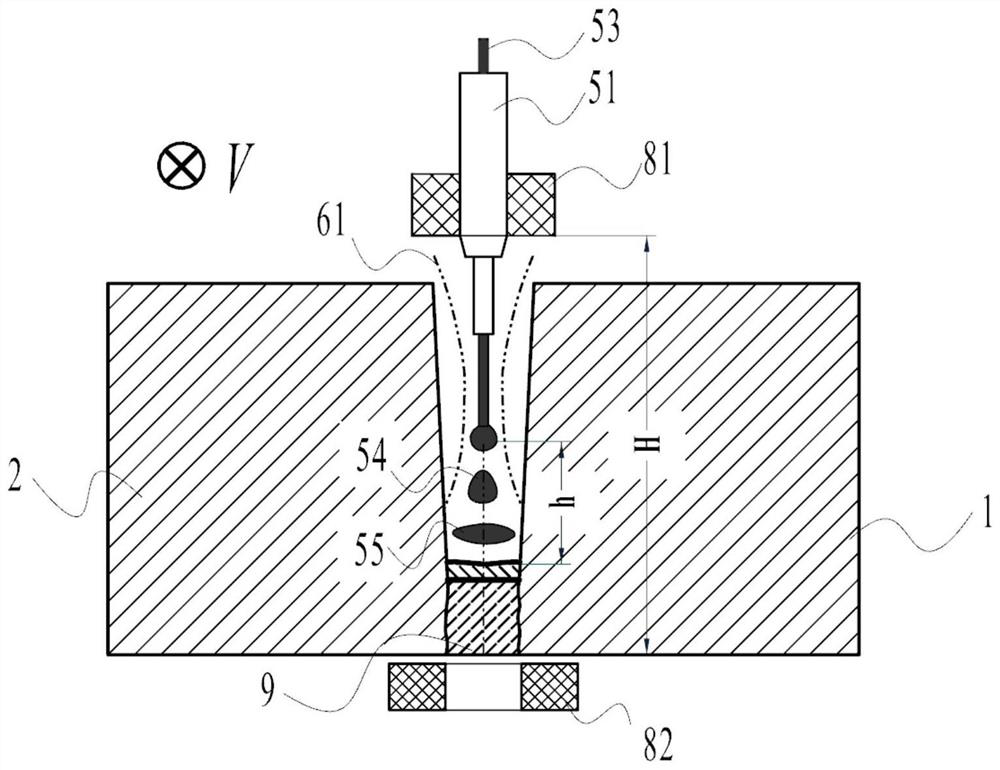

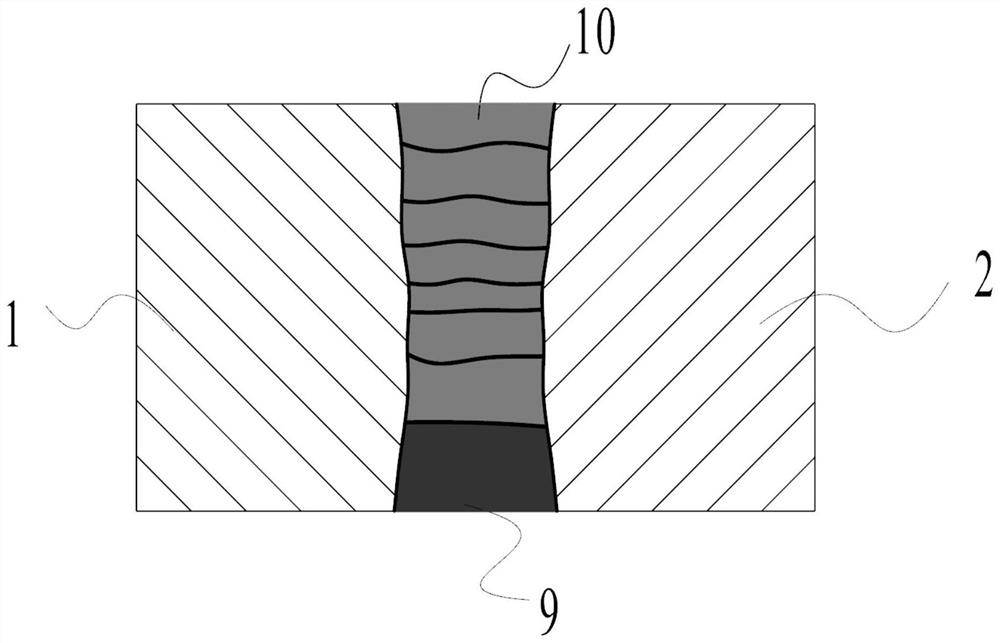

Low-power laser-induced double-pulse TIG welding method for aluminum-based composite materials

InactiveCN111545917AEfficient weldingImprove the vibration effectLaser beam welding apparatusHigh energyComposite plate

The invention discloses a low-power laser-induced double-pulse TIG welding method for aluminum-based composite materials. The invention relates to the field of welding of the aluminum-based compositematerials, in particular to a low-power laser-induced double-pulse TIG welding method for the aluminum matrix composite materials. The invention aims to solve the problems of low joint strength, obvious defects such as air holes, high energy consumption and welding limitation in the existing aluminum-based composite material welding process. Low-power pulse laser and double-pulse TIG arcs are adopted as composite heat sources, a welding path is set, and the composite heat sources act on an aluminum-based composite plate fixed by a welding clamp. The method is used for welding the aluminum-based composite materials, the vibration and stirring effects on a welding pool can be enhanced through pulse laser and the double-pulse TIG arcs, the exhaust of gas in the welding pool is promoted, the occurrence of defects such as air holes in joint weld joints can be greatly reduced or even avoided, and meanwhile, the effect of refining grains can be achieved.

Owner:HENAN POLYTECHNIC UNIV +1

Precision injection mold

InactiveCN111993644AFirmly connectedEasy inspection and maintenanceCoatingsEngineeringVacuum chamber

The invention provides a precision injection mold which comprises a vacuum chamber, a liquid storage chamber and a decision box. The top of the vacuum chamber communicates with the liquid storage chamber through a lower through pipe, a plastic melt is stored in the liquid storage chamber, the bottom of the vacuum chamber is provided with a forming chamber, the bottom of the forming chamber is provided with a semicircular sheet, the bottom of the semicircular sheet makes contact with the top of a guide limiting groove, the bottom of the guide limiting groove is fixedly connected with the uppersurface of a substrate through welding, the left part of the upper surface of the substrate is provided with a repairing chamber, the upper surface and the lower surface of the vacuum chamber are provided with an inflow port and an outflow port correspondingly, the inner rear surface of the vacuum chamber is fixedly provided with a transverse limiting strip and a longitudinal limiting strip through welding, and the upper surface of the transverse limiting strip is in contact with the lower surface of a transverse guide arm. According to the technical scheme, the technical problems in the priorart that the device does not have the capability of absorbing and pumping air inside the device, and automatic cover sealing, excitation acceleration forming, automatic inspection and repair and thelike cannot be achieved are solved, and the application and popularization are facilitated.

Owner:黄笃莲

Die-casting forming process of gearbox clutch shell

The invention relates to a die-casting forming process of a gearbox clutch shell. The limitation that a traditional die-casting process depends on actual production experience and a repeated trial-and-error method to improve the quality of a gearbox clutch shell is improved; CAE simulation is conducted on the gearbox clutch shell die-casting process through ProCAST software, die-casting technological parameters under the condition that defects such as shrinkage porosity and shrinkage cavity are minimum are obtained, and a needed die-casting die is analyzed, judged and formulated; and meanwhile, the die-casting die of the gearbox clutch shell is provided with the corresponding exhaust grooves and the multiple ejection mechanisms, air in the die-casting die can be exhausted in time in the mold filling process, and thus the defects of insufficient pouring, air pores and the like are avoided.

Owner:宁波杰达模具机械有限公司

Refiring method of imitating Song Junguan porcelain based on nano-iron oxide glaze and firing series of imitating Song Junguan porcelain

The invention relates to a re-sintering method for firing imitated Song Jun official porcelains based on a nano ferric oxide glaze and series of fired imitated Song Jun official porcelains. According to the method, nano ferric oxide is added to a basic glaze and is directly glazed in a form of a basic ingredient of the glaze and then fired, so that the defects that a conventional re-sintered Song Jun official porcelain process is low in yield, complex in sintering process, too bright in color, too straight in color, opacifying effect is not obvious and the like can be overcome; and the purpose that the re-sintered Song Jun official porcelains have the glaze colors of powdery cyan, celeste, azure, grayish blue and the like of series of Song Jun official porcelains can be achieved by controlling the color of a glaze layer by controlling and adjusting the parameters of the mass ratio of the nano ferric oxide in the basic glaze, the firing temperature and the like. In addition, a nano material has the characteristics of being high in diffusion ability in Jun porcelain glaze firing, and beneficial to uniform distribution of a coloring agent in a Jun porcelain glaze layer, so that a sintered Jun porcelain product is uniform in color, the viscosity of the glaze layer in the glaze firing process can be effectively reduced, the defects of air holes and the like on the surface of the glaze porcelain are avoided, and the firing success rate of the Jun porcelain is increased.

Owner:XUCHANG UNIV

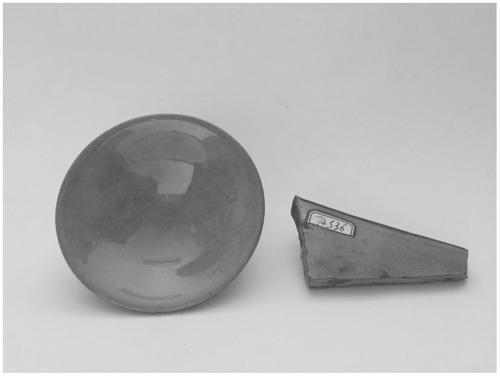

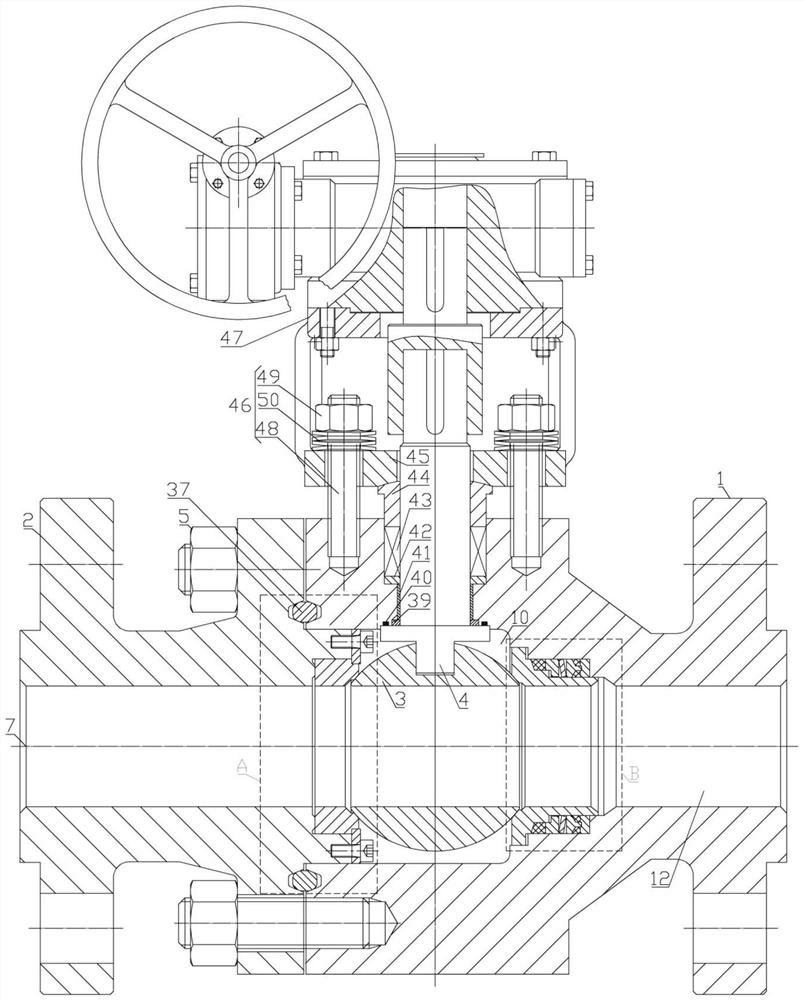

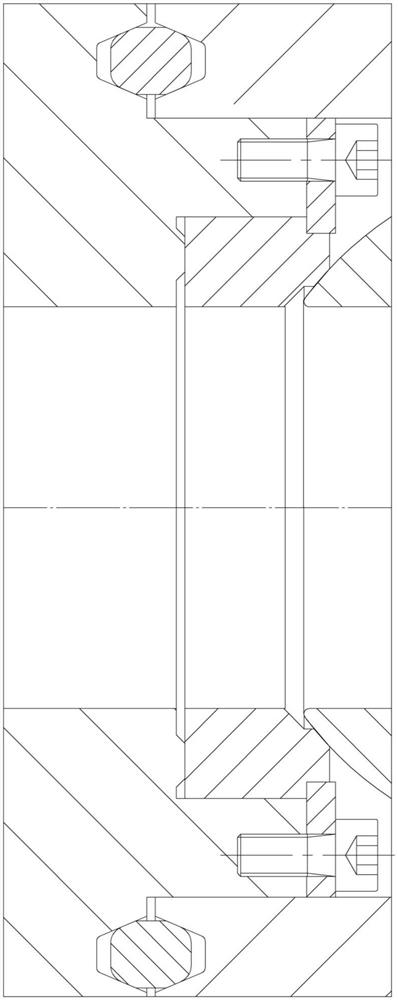

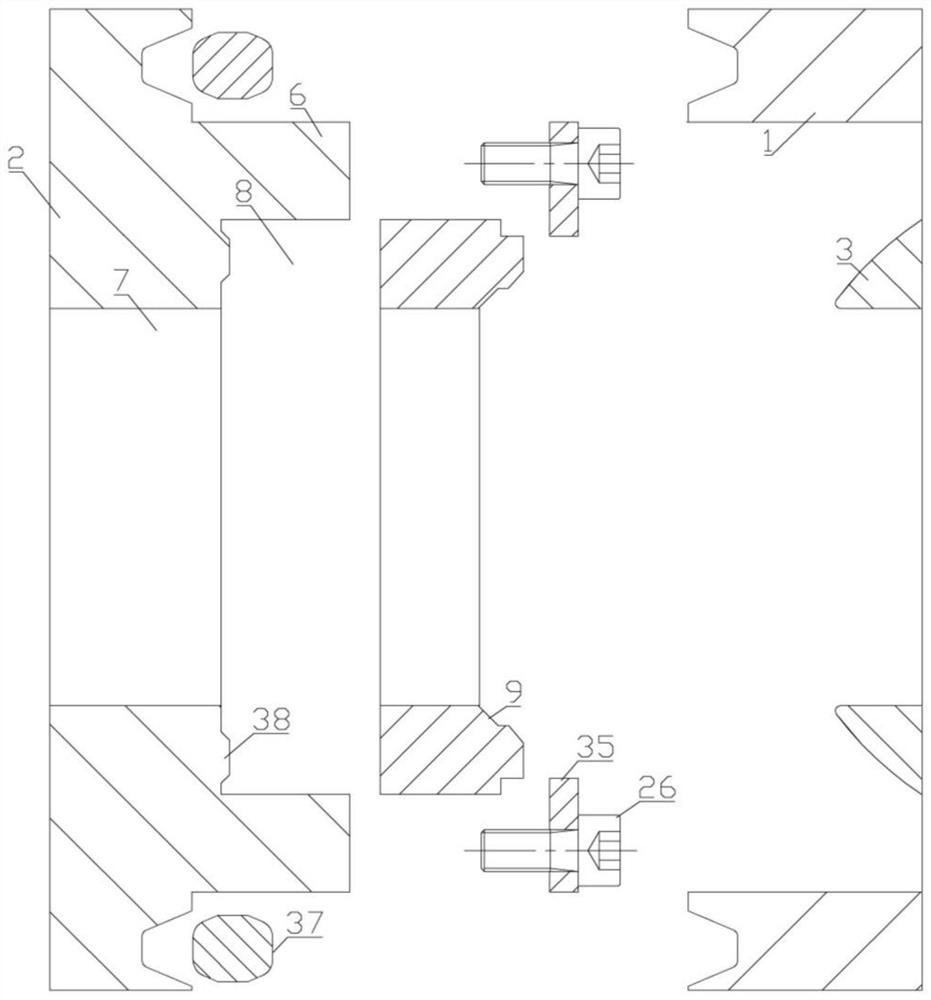

Two-piece type hard sealing floating ball valve

PendingCN114413024AAvoid defects such as poresEasy to installSpindle sealingsPlug valvesValve seatBall valve

The invention discloses a two-piece type hard sealing floating ball valve, and relates to a clamp, the two-piece type hard sealing floating ball valve comprises a valve body, a valve cover, a ball body and a valve rod, the valve body and the valve cover are both obtained through a forging process, the valve cover is arranged on one side of the valve body, and the valve body and the valve cover are connected through a connecting bolt set; a cylindrical limiting block is arranged on one side of the valve cover, a first valve seat is embedded in the cylindrical limiting block, and a mounting space, a second cylindrical space and a second medium channel are sequentially formed in the valve body; the cylindrical limiting block is inserted into the mounting space and is sealed through a sealing device, a second valve seat is arranged in the second cylindrical space, and a multi-sealing assembly is arranged between the second valve seat and the second cylindrical space; the ball body is arranged between the first valve seat and the second valve seat, the top of the ball body is connected with a valve rod, and the top of the valve rod penetrates through the valve body and then is connected with a sealing driving device; medium leakage can be effectively prevented, and the sealing performance of equipment can be effectively improved.

Owner:ANHUI TUNXI HIGH PRESSURE VALVE

High-strength steel thick plate narrow gap welding method and system based on paraxial laser-coaxial wire feeding-electromagnetic field synergy

PendingCN113857672AAvoid bulkyCrack suppressionLaser beam welding apparatusHeat-affected zoneEngineering

The invention discloses a high-strength steel thick plate narrow gap welding method based on paraxial laser-coaxial wire feeding-electromagnetic field synergy. The method mainly comprises the following steps of providing a first base material and a second base material, carrying out butting to form a narrow gap joint, and finishing backing welding by adopting laser self-fusion welding; providing a laser wire filling welding system; starting the laser wire filling welding system, a weld joint surface contour detector, a first laser head, a coaxial wire feeding head, a second laser head, a first electromagnetic coil, a second electromagnetic coil and a paraxial nozzle moving synchronously, and carrying out welding. The invention further discloses a high-strength steel thick plate narrow gap welding system based on the paraxial laser-coaxial wire feeding-electromagnetic field synergy. According to the high-strength steel thick plate narrow gap welding method and system based on the paraxial laser-coaxial wire feeding-electromagnetic field synergy, the problems of large heat-affected zone structure and cracks caused by large welding heat input in an existing high-strength steel thick plate narrow gap laser welding process are solved, and the outstanding advantages of being good in process stability, high in welding efficiency and the like are achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

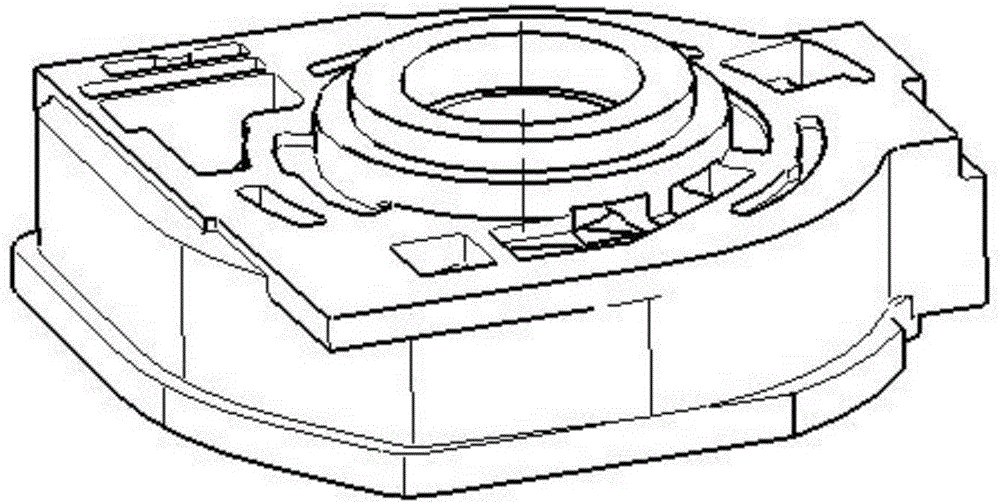

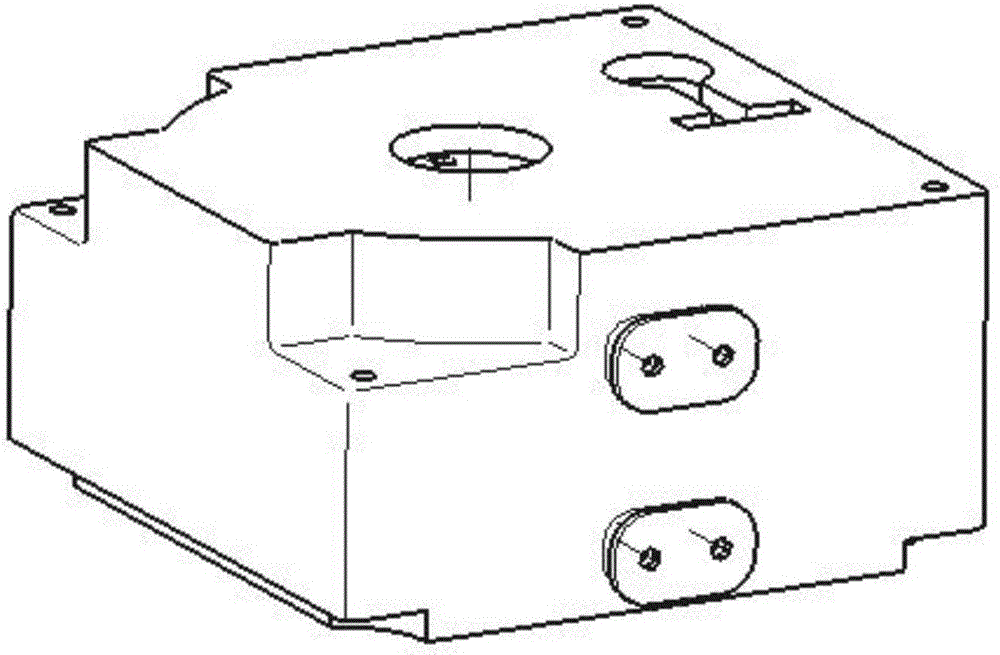

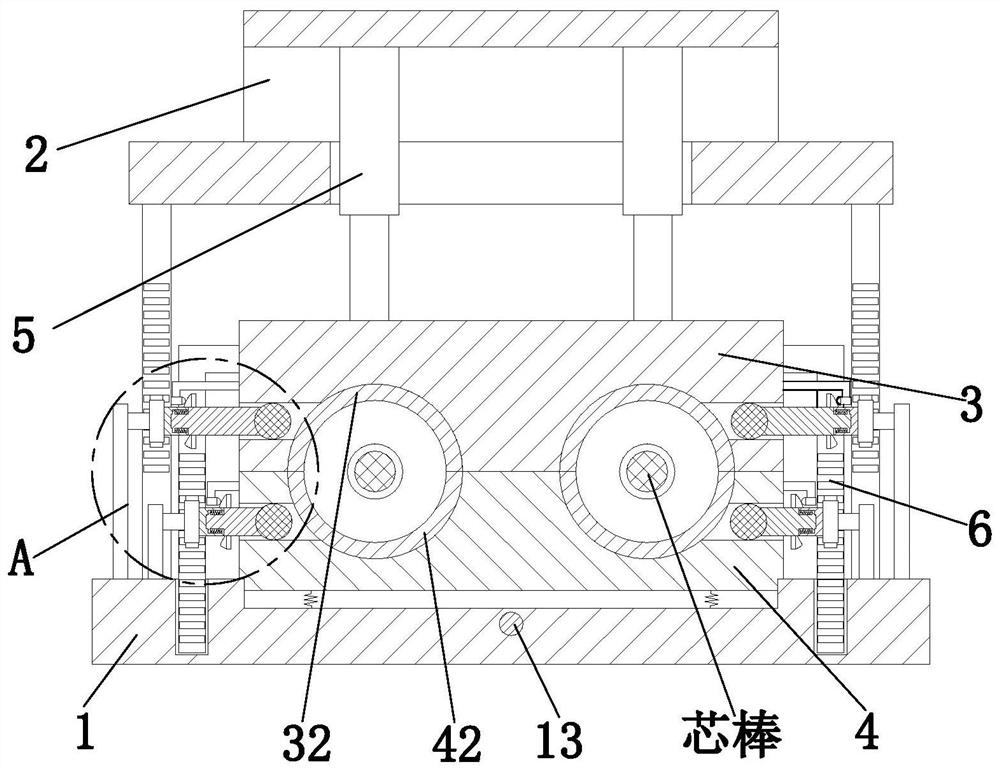

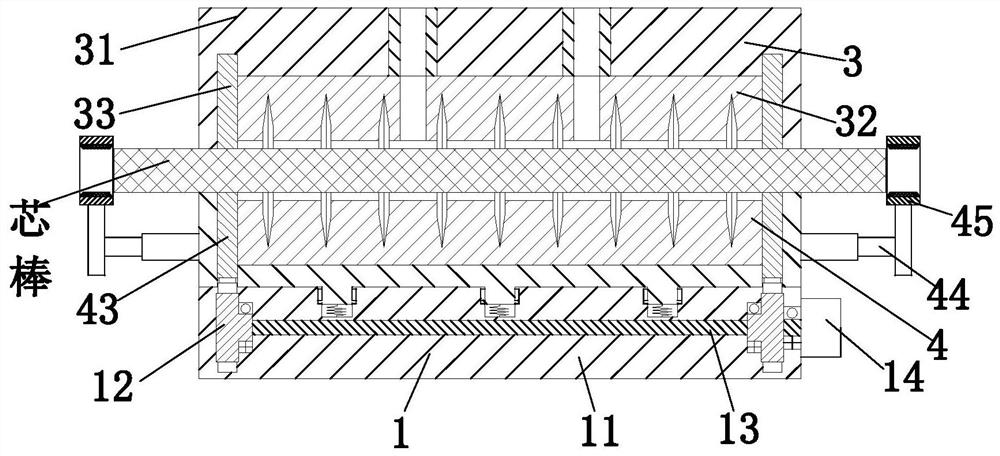

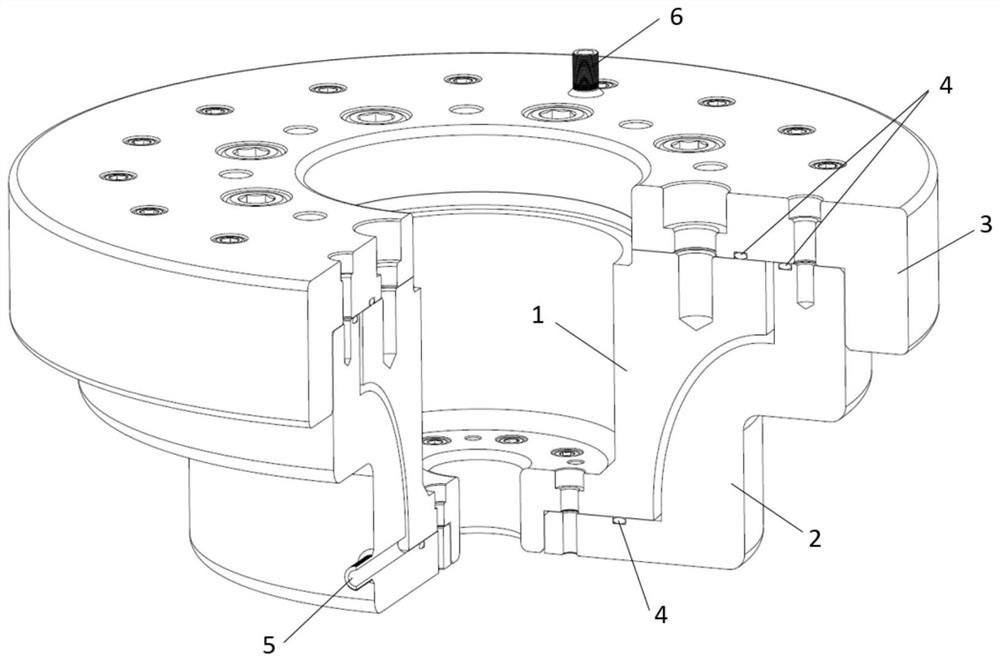

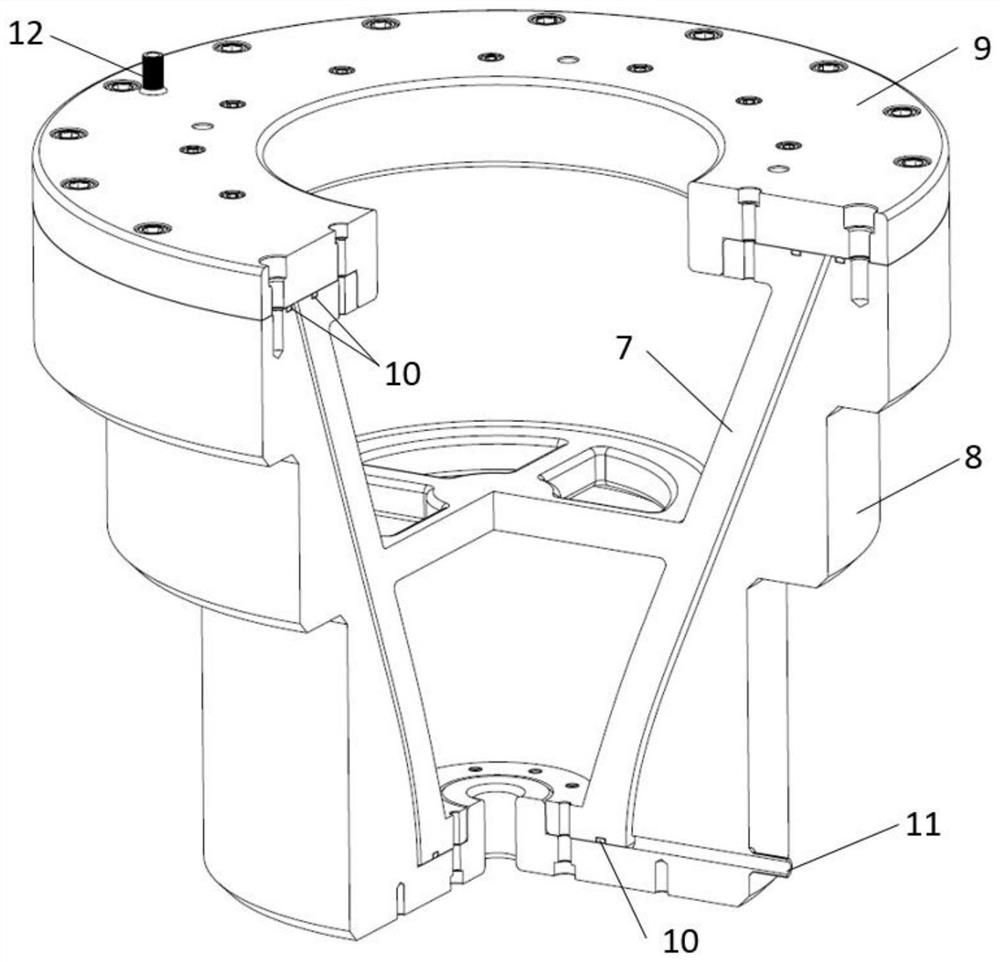

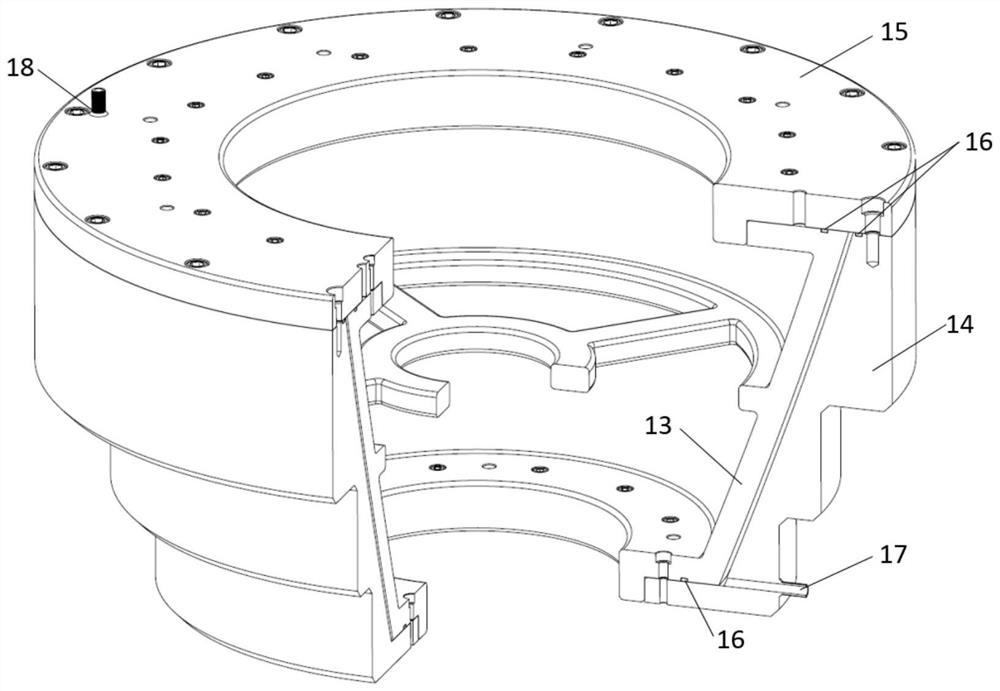

A composite insulator manufacturing process

The invention relates to a manufacturing process of a composite insulator, which uses an injection molding mold, the injection molding mold includes a base frame, a mounting frame, an upper mold, a lower mold, a lifting cylinder and a vibration mechanism, and the above-mentioned injection molding mold is used to make a composite insulator. The specific process flow of the type insulator is as follows: mandrel forming, mandrel grinding, injection assembly, ejection and demoulding, and shape trimming. The upper mold includes the main body of the upper mold, the upper shaping block and the upper driven gear. The lower mold includes the main body of the lower mold, Lower shaping block, lower driven gear, telescopic cylinder and fixed ring. The invention can drive the rubber material to shake within a certain range during the injection process, ensure the uniform distribution of the rubber material in the mold, avoid defects such as air holes caused by uneven distribution of the rubber material, and can drive the mold through the vibration mechanism to carry out the injection process during demoulding. Vibration achieves the purpose of accelerating the separation speed of the mold and the silicone rubber shed.

Owner:南京电气绝缘子有限公司

Preparation mold and preparation method of integrated composite material spray pipe

ActiveCN114434743AIncrease frictionPrevent slippingTubular articlesComposite materialCeramic materials

The invention discloses a preparation mold of an integrated composite material spray pipe, which comprises a core mold head section expansion layer preparation mold and a core mold tail section expansion layer preparation mold detachably connected with the core mold head section expansion layer preparation mold, the core mold tail section upper cone expansion layer preparation mold, the core mold tail section middle cone expansion layer preparation mold and the core mold tail section lower cone expansion layer preparation mold are detachably connected in sequence, and the diameter from the core mold tail section upper cone expansion layer preparation mold to the core mold tail section lower cone expansion layer preparation mold is gradually increased. The invention further provides a preparation method of the integrated composite material spray pipe, the expansion layer is subjected to roughening treatment, the cloth bag is prevented from sliding in the winding and curing process, meanwhile, in the product curing process, the expansion layer is heated to expand, overall pressurization on the inner molded surface of the product is achieved, the product compactness degree is increased, and the service life of the product is prolonged. And the ablation resistance of the integrated composite material spray pipe is improved.

Owner:长春长光宇航复合材料有限公司

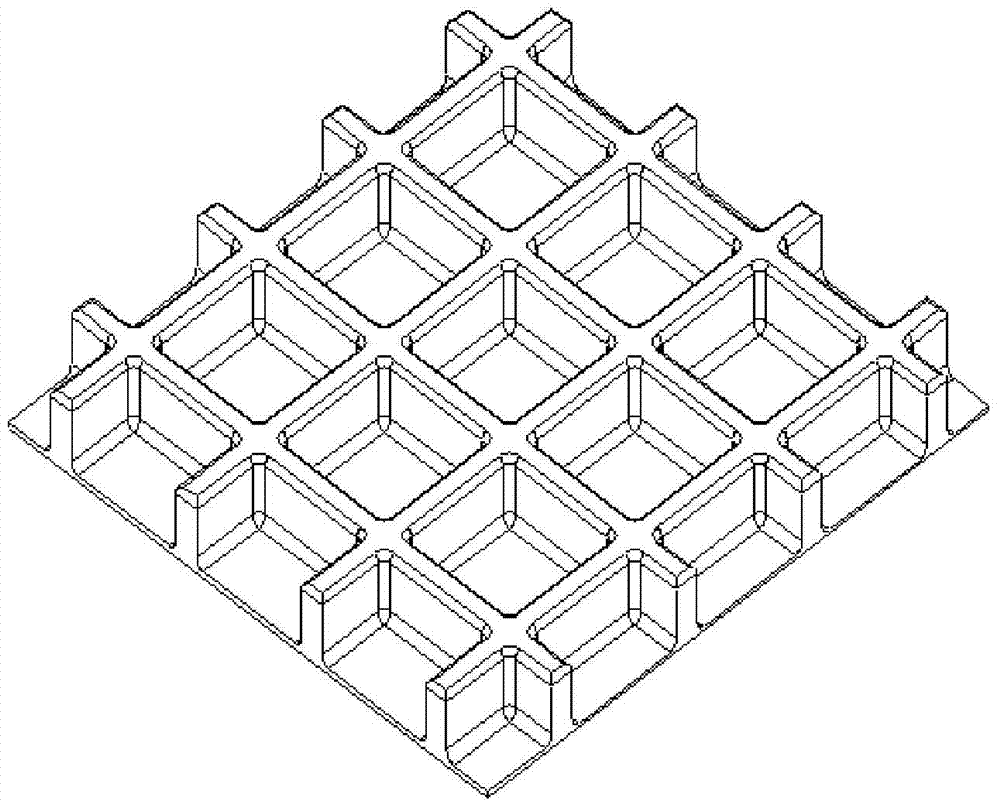

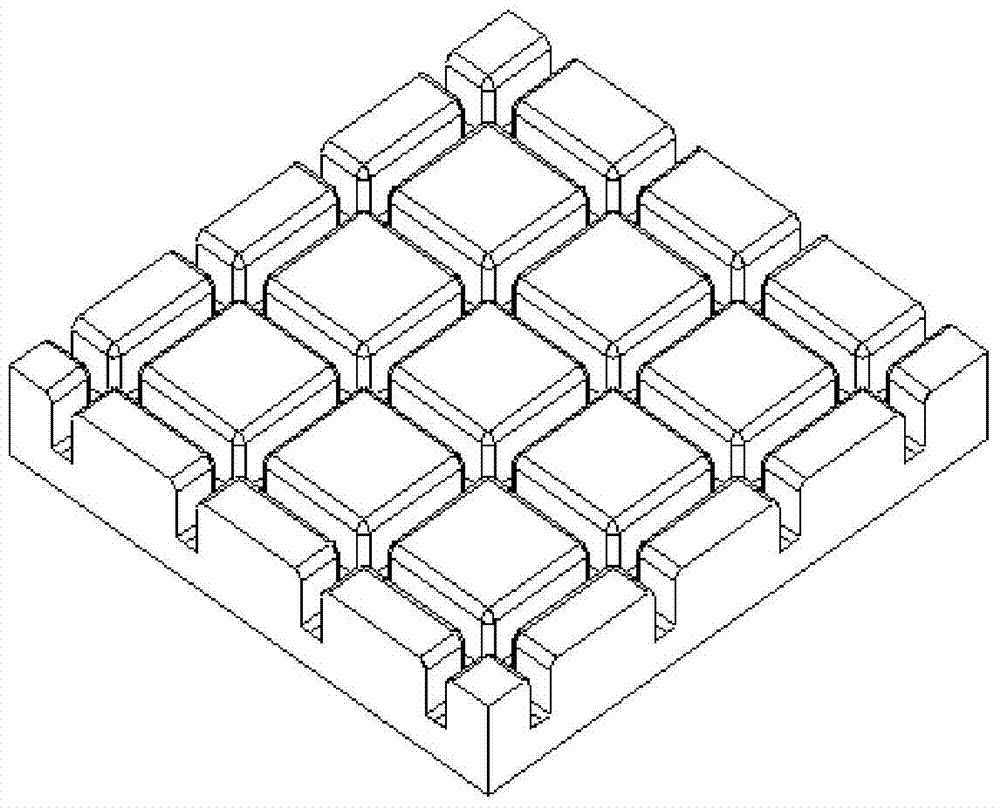

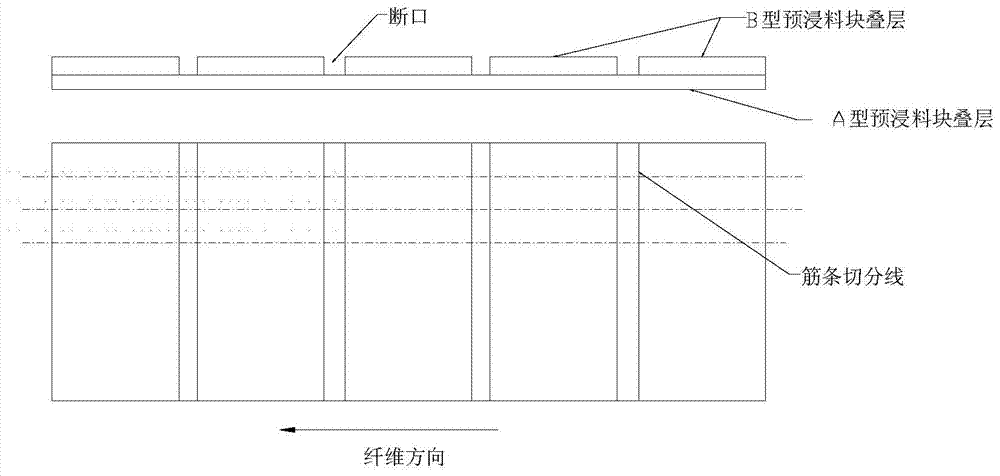

A carbon fiber/high toughness epoxy composite material grid rib forming method

The invention relates to a carbon fiber / high tenacity epoxy composite material grid fillet molding method, and belongs to the technical field of grid ribbing structure composite material molding. The cross section of a grid fillet prepared with the molding method is large, the common depth-to-width ratio is 1-3, the depth ranges from 15 mm to 20 mm, and the carbon fiber / high tenacity epoxy composite material grid fillet molding method In particular, the invention relates to a T800 carbon fiber / epoxy hot melting method prepreg grid fillet skin class structure molding method. The carbon fiber / high tenacity epoxy hot melting pre-soaking silk material system which is low in flue containing amount and high in filter size content is adopted in the method, large-section size fillet molding technical researches are developed, adaptation improvements are carried out on the pre-soaking silk paving process, the glue absorbing curving process, the skin interface interlayer bonding process and the like are achieved, and application to grid fillet standard structure pieces is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for preparing Al-Cr composite coating through laser cladding

ActiveCN111621780APromote absorptionAvoid crackingMetallic material coating processesAl powderAbrasive blasting

The invention discloses a method for preparing an Al-Cr composite coating through laser cladding, and belongs to the technical field of aluminum alloy surface treatment. The method comprises the following steps of uniformly mixing Al powder and Cr powder, and drying; grinding off an oxide layer on the surface of an aluminum alloy plate by using abrasive paper, cleaning by using ultrasonic waves, and blow-drying; then carrying out surface sand blasting treatment so as to increase the absorption of laser; cladding an Al-Cr composite coating on the surface of an aluminum alloy by adopting a lasercladding method and an argon shield coaxial powder feeding mode; and under the action of a laser beam with high energy density, Al and Cr react to generate an AlxCry intermetallic compound, and jointly forming the composite coating by the metal phase and the ceramic phase. The Al-Cr composite coating has the advantages of being good in combination with a base material, not prone to cracking, highin hardness, good in abrasion resistance and the like, and therefore the surface of the aluminum alloy is strengthened.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

Wet-seal box sand for rapid thermit welding

InactiveCN110039172AAvoid osmosisPrevent leakageAlumino-thermic welding apparatusIon exchangeConstruction aggregate

The invention discloses wet-seal box sand for rapid thermit welding. The wet-seal box sand comprises 10-35 parts of bentonite, 120-180 parts of quartz sand and 5-15 parts of water. Activating treatment is carried out on bentonite, and sodium ions are added to form calcium-based sodium modified bentonite. The quartz sand and the calcium-based sodium modified bentonite are uniformly mixed by a sandmixer, and are wrapped around the quartz sand particles by utilizing the physical adsorbability of the bentonite; then uniformly adding the water for wet mixing, greatly increasing the viscosity and ion exchange adsorbability of the bentonite after water absorption, and enabling the combination of the bentonite and the quartz sand particles to be more tight. The wet-seal box sand has relatively high viscosity, refractoriness and filling capacity, and can effectively fill the edge gap of the thermit welding sand mold in rapid thermit welding, so that the rapid sealing can be realized, the leakage of high-temperature molten steel on the contact surface of the sand mold and the steel rail can be avoided, and the safe and smooth thermit welding can be ensured.

Owner:施密特钢轨技术(昆山)有限公司

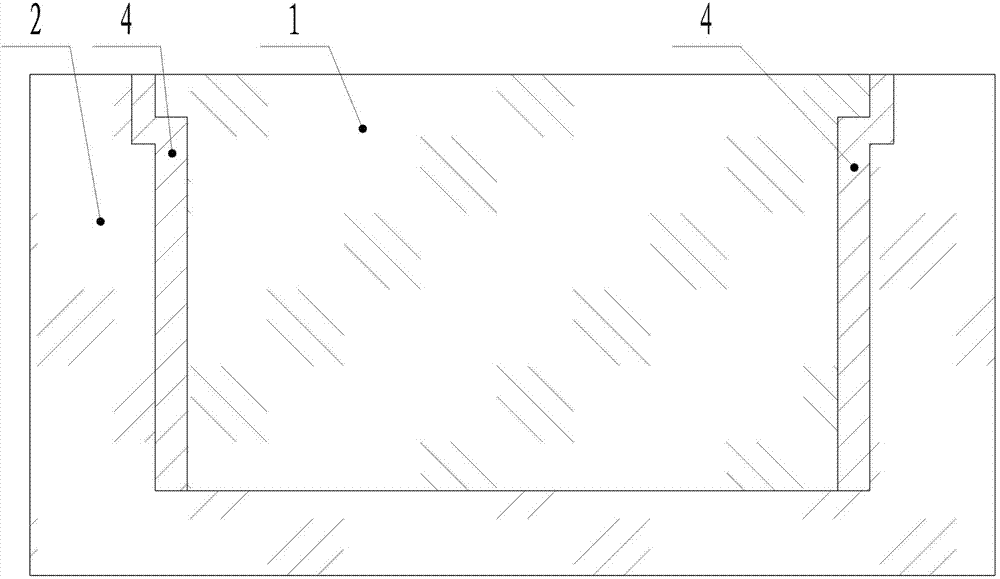

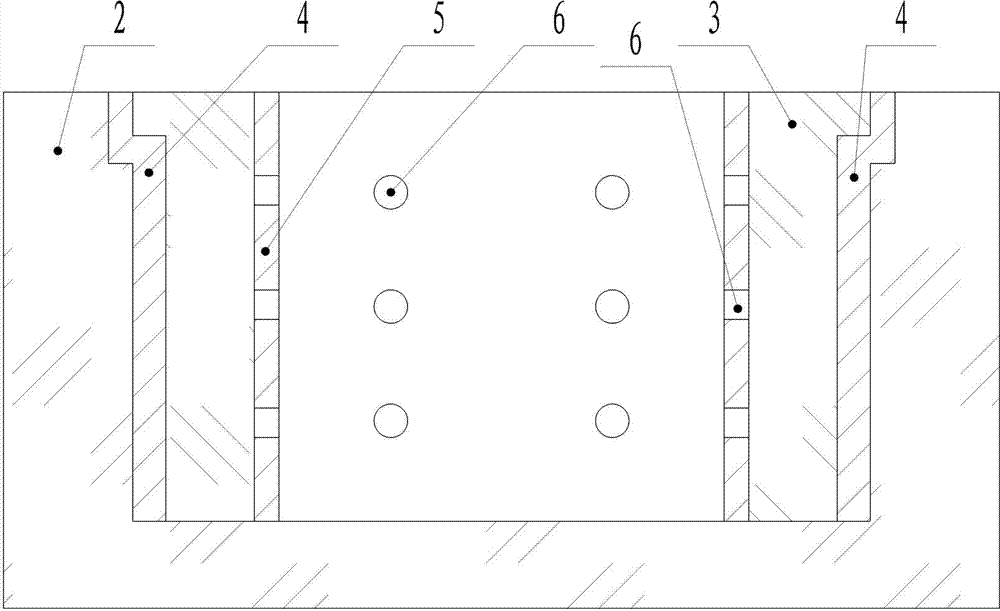

Technique for producing large and medium-sized cylindrical iron castings through clay green sand molding

InactiveCN103182476BGuaranteed StrengthGuaranteed stiffnessFoundry mouldsFoundry coresEconomic benefitsEnergy conservation

The invention relates to the processing field of iron castings, in particular to a technique for producing large and medium-sized cylindrical iron castings through a clay green sand molding. The technique achieves the application of the clay green sand molding process in the production and processing of the large and medium-sized iron castings, and is achieved through the following technical steps: molding sand preparation, modeling, core making, mold assembling, teeming, shakeout, cleaning, inspection and repair. The core making comprises the steps as follows: 1, designing a sand core structure, wherein the sand core is designed to be provided with a through hole structure or a blind hole structure in an axial direction, so that a cavity type structure is formed; 2, drawing drawings of an internal mold and an external mold; 3, adopting a steel plate to produce the internal mold and the external mold, wherein a plurality of exhaust through holes are formed uniformly in the internal mold; and 4, producing the cavity sand core. The technique provided by the invention is reasonable, simple, and convenient to implement; moreover, the implementation meets the requirements for energy conservation and emission reduction, the production cost can be saved effectively, the production technology process can be shortened, the production efficiency can be improved, and the economic benefits of enterprises can be increased; and the technique is mainly used for producing iron castings provided with the cylindrical characteristic such as middle-segment, bottom-segment castings and the like of a carbon disulfide gasification reacting furnace.

Owner:阳城县煜锟铸造厂 +1

Method of Laser Cladding Cemented Carbide Coating on Turbine Blade Shroud

ActiveCN103898502BQuality improvementSimple processMetallic material coating processesCarbide coatingTurbine blade

The invention belongs to the technology of metal surface treatment and particularly relates to an improved method for laser cladding of a hard alloy coating on a crown of a turbine blade. Laser three-dimensional forming equipment is adopted for carrying out laser cladding on the hard alloy coating. The method comprises the following steps: cleaning the blade; clamping the blade; vacuum-drying the hard alloy powder; and carrying out laser cladding. The invention provides an improved method for laser cladding of the hard alloy coating on the crown of the turbine blade, so that the steps are simplified, the operating time is shortened and the cladding efficiency is improved. Meanwhile, the defect of pores generated in the cladding process and the like is avoided, and the quality of the hard alloy coating is improved.

Owner:AECC AVIATION POWER CO LTD

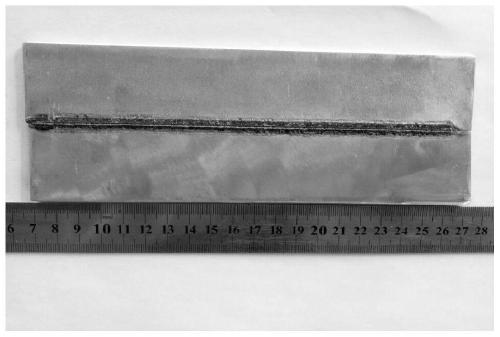

Method for improving wear resistance and rolling contact fatigue performance of steel rails

InactiveCN107099794AInhibitionStrong dislocationMetallic material coating processesRolling contact fatigueAlloy

The invention discloses a method for improving wear resistance and rolling contact fatigue performance of steel rails. The method comprises the step of cladding surfaces of the steel rails with Fe-based powder by using a laser under argon shield and is characterized in that the Fe-based alloy powder is prepared through adding 0.4% to 2% by mass of lanthanum oxide powder into Fe-based powder. The steel rails obtained through treatment by the method are high in wear resistance and good in rolling contact fatigue performance.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com