Precision injection mold

A kind of injection mold, precision technology, applied in the direction of coating, etc., can solve the problems of vibration accelerated molding, can not realize automatic capping, does not have the ability of air absorption and drainage, etc., to achieve low cost, reliable connection, convenient inspection and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

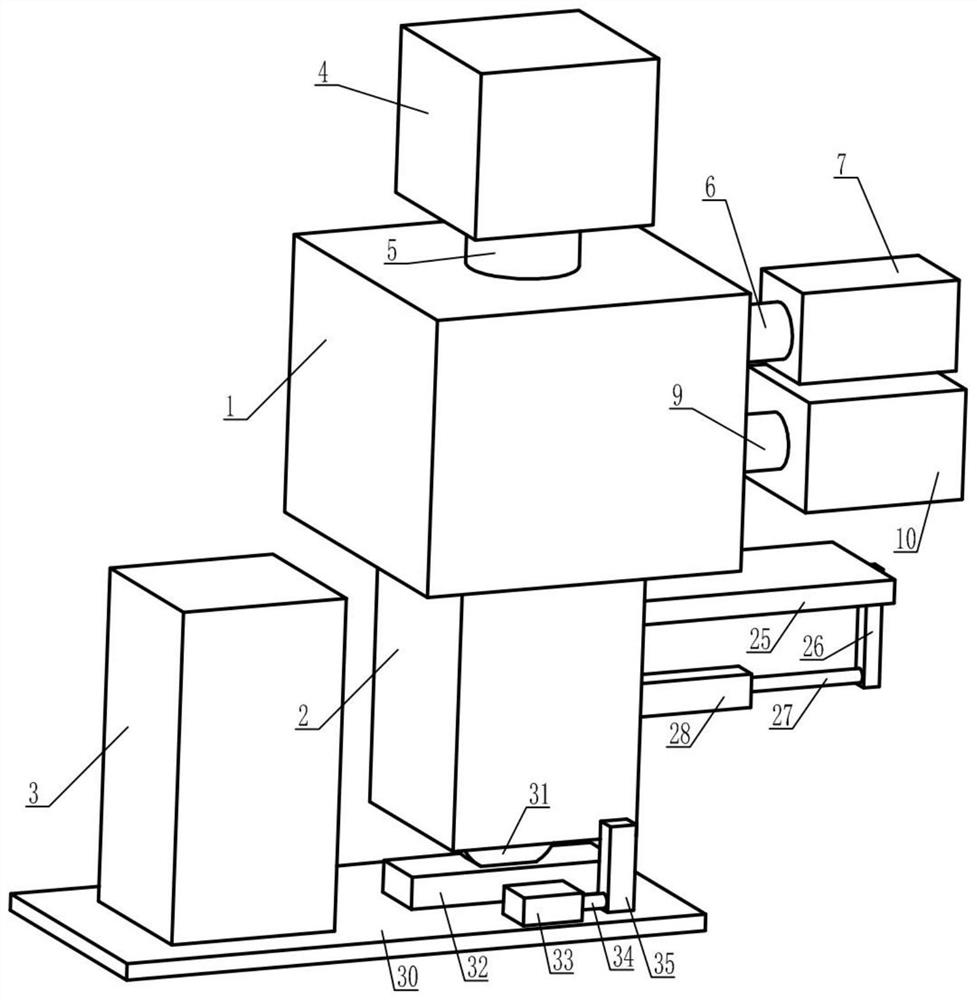

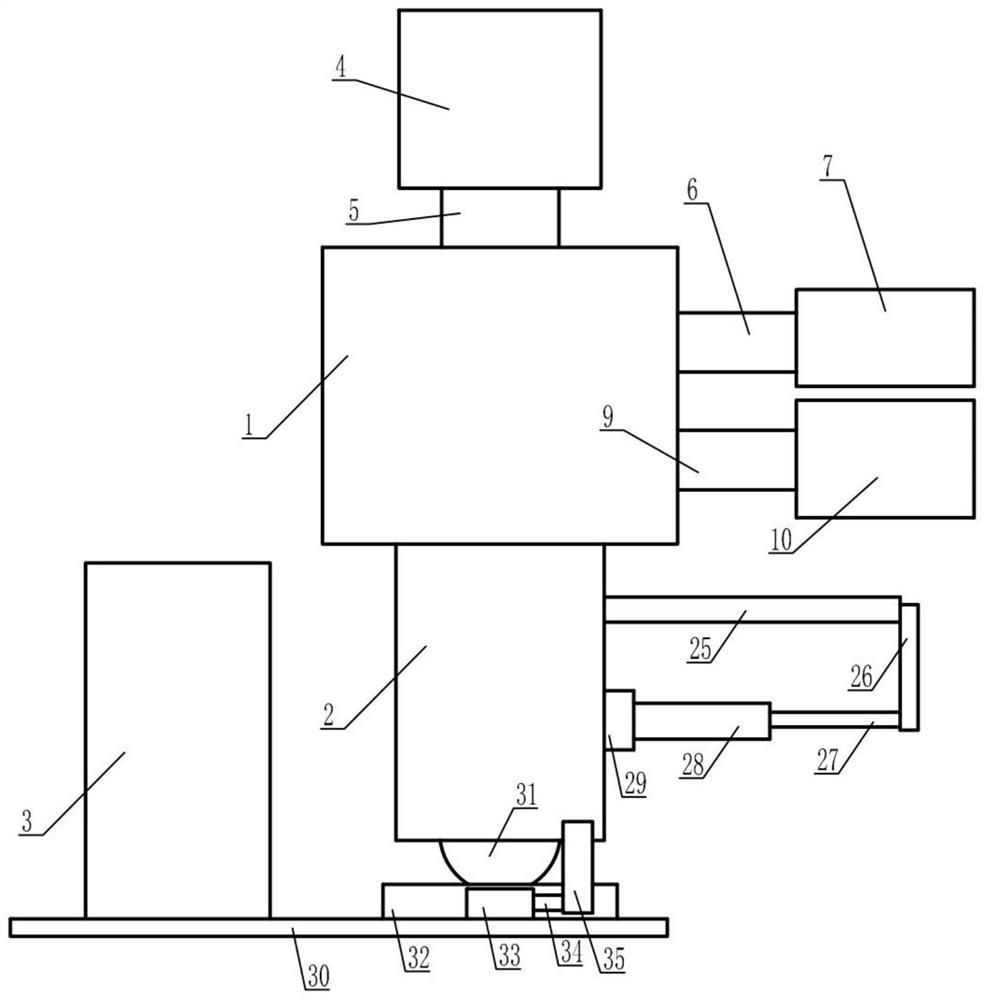

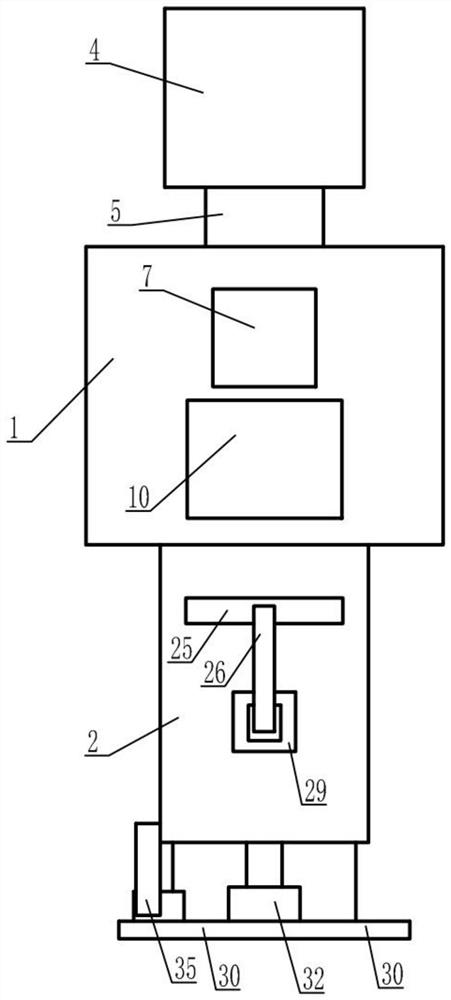

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] refer to Figure 1 to Figure 10 , a precision injection mold provided by the present invention includes a vacuum chamber 1, a liquid storage chamber 4, and a decision box 48. The top of the vacuum chamber 1 communicates with the liquid storage chamber 4 through a downcomer 5, and the liquid storage chamber The interior of the chamber 4 stores plastic melt, the bottom of the vacuum chamber 1 is provided with a molding chamber 2, and the bottom of the molding chamber 2 is provided with a semi-circular sheet 31, and the bottom of the semi-circular sheet 31 is in contact with the guide limiting groove 32, the bottom of the guide limiting groove 32 is fixedly connected with the upper surface of the substrate 30 by welding, the left part of the upper surface of the substrate 30 is provided with a repair chamber 3, and the vacuum chamber 1 The upper and lower surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com