Low-power laser-induced double-pulse TIG welding method for aluminum-based composite materials

An aluminum-based composite material, laser-induced technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high energy consumption, low joint strength, etc., to improve the shock effect, promote joint strength, energy saving and environmental protection welding The effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

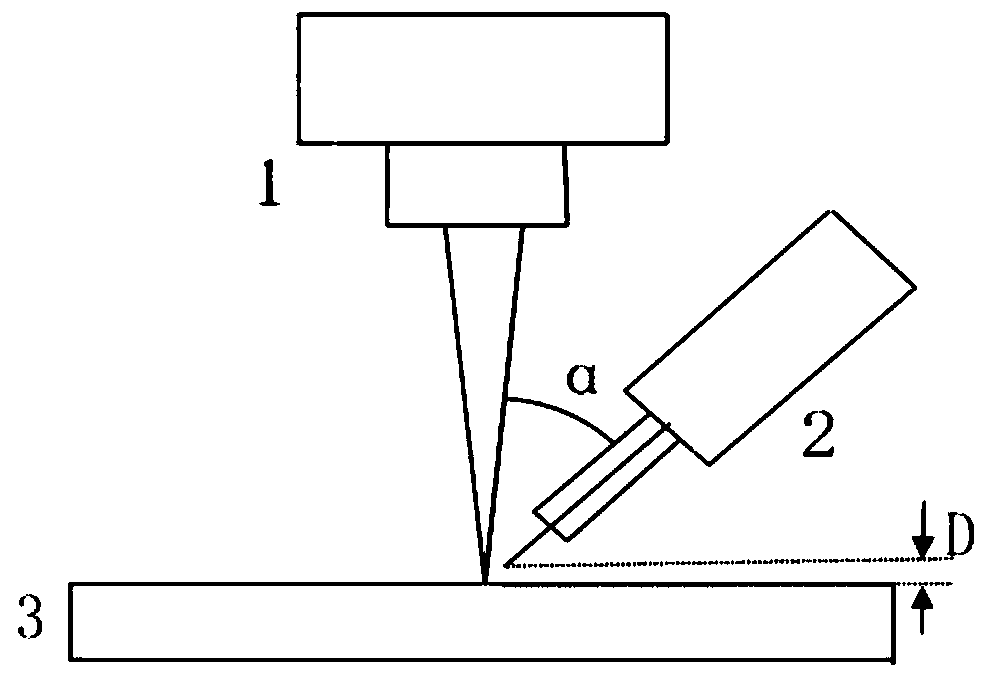

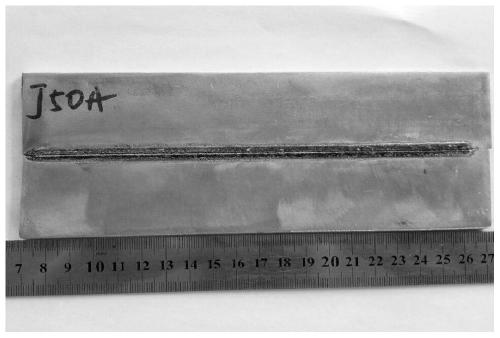

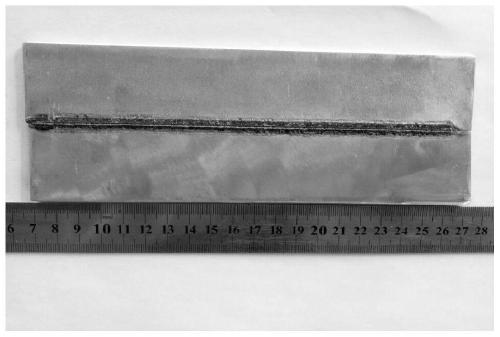

[0013] Specific Embodiment 1: In this embodiment, the low-power laser-induced double-pulse TIG welding method for aluminum-based composite materials adopts low-power pulsed laser and double-pulse TIG arc as the composite heat source, sets the welding path, and applies the composite heat source to the aluminum substrate fixed by the welding fixture. On composite material sheets, it achieves good welding of materials.

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the low-power laser-induced double-pulse TIG welding method of aluminum-based composite materials is carried out according to the following steps:

[0015] 1. Cutting and grinding of aluminum matrix composite materials: Cut the size of aluminum matrix composite materials according to actual needs, and then use an angle grinder to grind each surface of aluminum matrix composite materials until bright colors appear, and obtain aluminum matrix composite material parts to be welded;

[0016] 2. Defilming of aluminum matrix composite materials: use sandpaper to grind the butt joint surface of the aluminum matrix composite material parts to be welded, and clean the polished aluminum matrix composite material parts with ultrasonic cleaning for 15-20 minutes, and then use alcohol to clean them for 10-20 minutes. After 15 minutes, use a hair dryer to dry the residual alcohol on the sur...

specific Embodiment approach 3

[0026] Specific Embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 3, when the two pieces of aluminum-based composite material parts to be welded after removing the film are placed on the welding fixture in a docking manner and fixed, the Ti flakes or Ti alloy flakes with a thickness of 0.1-1 mm are placed in the middle position. Others are the same as in the first or second embodiment.

[0027] This embodiment can realize in-situ enhanced welding of materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com