Method for improving heavy-load wheel rail wear-resistant performance by laser cladding cobalt alloy coating

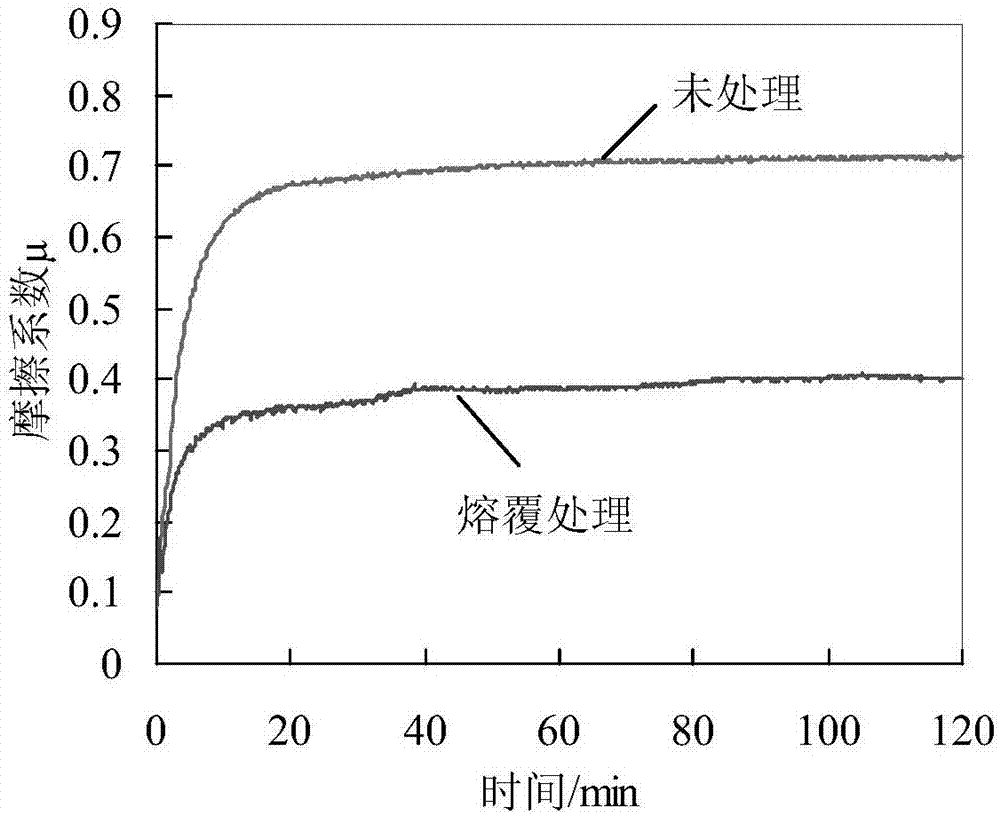

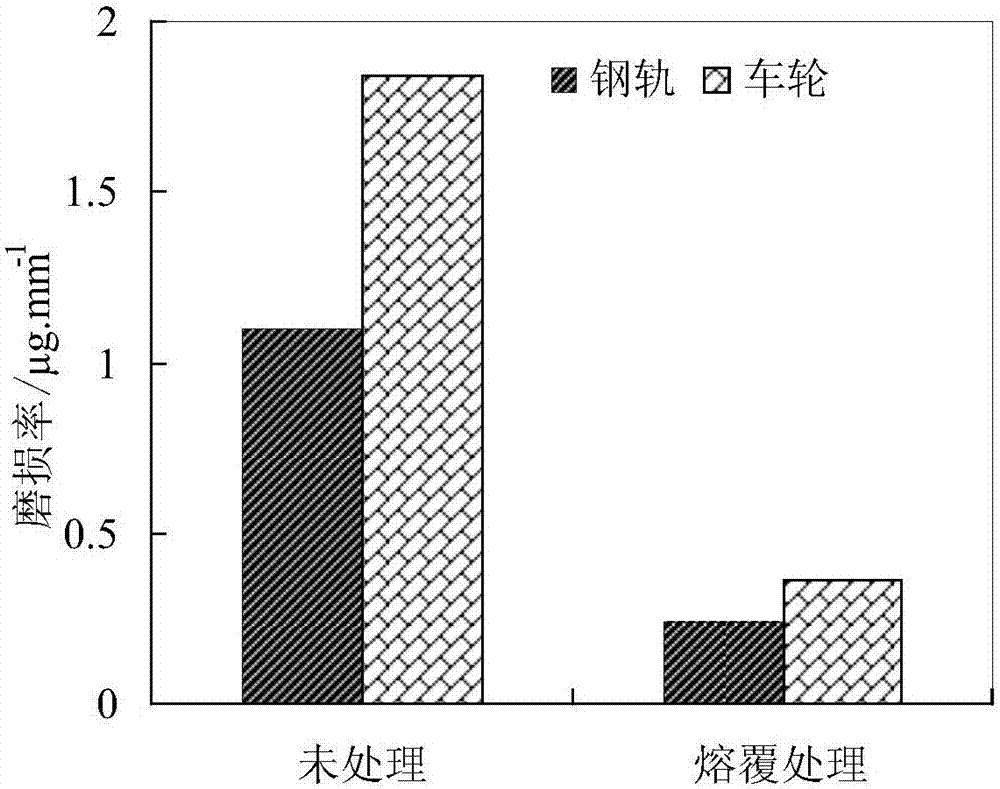

A laser cladding, cobalt alloy technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of crack porosity, uneven structure of cladding layer, wear resistance to be improved, etc., to improve wear resistance. , the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for improving the wear resistance of heavy-duty wheel rails by laser cladding cobalt alloy coatings, the method is:

[0018] Utilize the laser to clad the cobalt alloy powder on the heavy-duty wheel rim surface or the gauge angle of the heavy-duty rail (that is, the inner surface of the rail head facing the center of the track); the weight percentage content of the cobalt alloy powder is: 1.1% C, 1.0% Si, 1.5% Fe, 28.5% Cr, 1.5% Ni, 4.4% W, and the balance is Co. The diameter of the cobalt alloy powder was 100 μm.

[0019] In this example, the specific method of cladding cobalt alloy powder on the surface of the heavy-duty wheel rim or the gauge angle of the heavy-duty rail by using a laser is: the laser is a multi-mode cross-flow CO 2 Laser adopts multi-pass cladding method, the width of each cladding is 8mm, and the depth is 1.0mm; the overlap rate is 30%, and the energy density of the laser beam is 200W / mm 2 , the distance from the laser beam exit of the l...

Embodiment 2

[0025] A method for improving the wear resistance of heavy-duty wheel rails by laser cladding cobalt alloy coatings, the method is:

[0026] Cobalt alloy powder is clad on the surface of the heavy-duty wheel rim or the gauge angle of the heavy-duty rail by using a laser; the weight percentage content of the cobalt alloy powder is: 1.1% C, 1.0% Si, 1.5% Fe , 28.5% Cr, 1.5% Ni, 4.4% W, and the balance being Co. The diameter of the cobalt alloy powder was 50 μm.

[0027] In this example, the specific method of cladding cobalt alloy powder on the surface of the heavy-duty wheel rim or the gauge angle of the heavy-duty rail by using a laser is: the laser is a multi-mode cross-flow CO 2 Laser adopts multi-pass cladding method, each cladding width is 6mm and depth is 1.2mm; the overlap rate is 30%, and the energy density of the laser beam is 200W / mm 2 , the distance from the laser beam exit of the laser to the heavy-duty wheel rim surface or the gauge angle of the heavy-duty rail i...

Embodiment 3

[0029] A method for improving the wear resistance of heavy-duty wheel rails by laser cladding cobalt alloy coatings, the method is:

[0030] Cobalt alloy powder is clad on the surface of the heavy-duty wheel rim or the gauge angle of the heavy-duty rail by using a laser; the weight percentage content of the cobalt alloy powder is: 1.1% C, 1.0% Si, 1.5% Fe , 28.5% Cr, 1.5% Ni, 4.4% W, and the balance being Co. The diameter of the cobalt alloy powder was 150 μm.

[0031] In this example, the specific method of cladding cobalt alloy powder on the surface of the heavy-duty wheel rim or the gauge angle of the heavy-duty rail by using a laser is: the laser is a multi-mode cross-flow CO 2 Laser adopts multi-pass cladding method, each cladding width is 10mm and depth is 0.8mm; the overlap rate is 30%, and the energy density of the laser beam is 200W / mm 2 , the distance from the laser beam exit of the laser to the heavy-duty wheel rim surface or the gauge angle of the heavy-duty rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com