Casting preparation method of aluminum-based boron carbide composite material

A technology of aluminum-based boron carbide and composite materials, which is applied in the field of composite material preparation, can solve the problems of complex process and uneven distribution of boron carbide powder, and achieve the effect of simple process, uniform internal structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

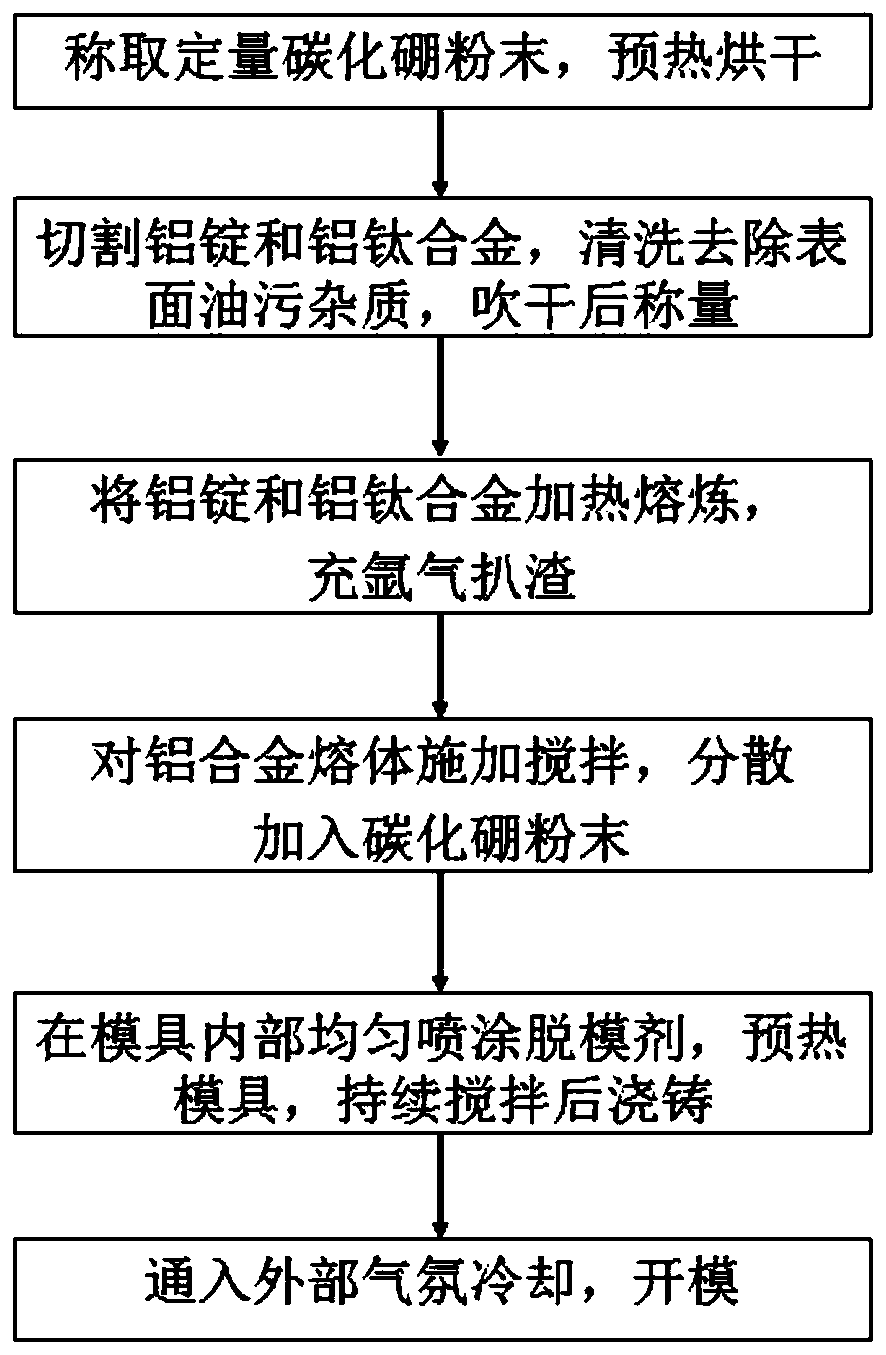

Method used

Image

Examples

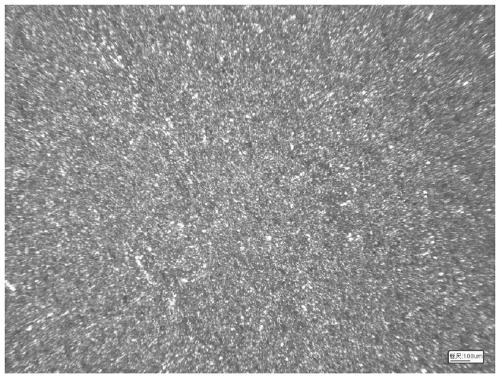

Embodiment 1

[0036] Step 1. Prepare materials, weigh 4.5kg of boron carbide powder with a particle size of 10um-50um, spread it in a container and put it into a resistance furnace, heat it at 370°C for 2.4h in the atmosphere, and then place it in a vacuum oven to dry Store at 120°C, vacuumize after passing inert gas.

[0037] Step 2. Take a certain amount of aluminum ingots and aluminum-titanium intermediate alloys, cut them into blocks, put them into the cleaning tank and use the aluminum product oil cleaning solution to clean to remove surface oil and impurities, rinse with 0.2-0.8MPa tap water after cleaning, and then Blow dry with 0.2-0.6MPa compressed air.

[0038] Step 3. Weigh quantitative aluminum ingots and aluminum-titanium intermediate alloys according to the proportion, place them in the crucible of a vacuum stirring furnace, evacuate to 40Pa, heat and melt to obtain an aluminum alloy melt with the composition shown in the table below, and wait for about 50 minutes to completel...

Embodiment 2

[0045] Step 1. Prepare materials, weigh 6.5kg of boron carbide powder with a particle size of 10um-50um, spread it in a container and put it into a resistance furnace, heat it at 380°C for 2.2h in the atmosphere, and then place it in a vacuum oven to dry Store at 150°C, vacuumize after passing inert gas.

[0046]Step 2. Take a certain amount of aluminum ingots and aluminum-titanium intermediate alloys, cut them into blocks, put them into the cleaning tank and use the aluminum product oil cleaning solution to clean to remove surface oil and impurities, rinse with 0.2-0.8MPa tap water after cleaning, and then Blow dry with 0.2-0.6MPa compressed air.

[0047] Step 3. Weigh quantitative aluminum ingots and aluminum-titanium intermediate alloys according to the proportion, place them in the crucible of a vacuum stirring furnace, evacuate to 40Pa, heat and melt to obtain an aluminum alloy melt with the composition shown in the table below, and wait for about 50 minutes to completely...

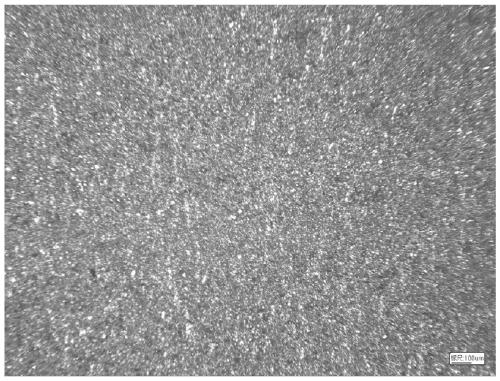

Embodiment 3

[0054] Step 1. Prepare materials, weigh 9.2kg of boron carbide powder with a particle size of 10um-50um, spread it in a container and put it into a resistance furnace, heat it at 440°C for 1.6h in the atmosphere, and then place it in a vacuum oven to dry Store at 170°C, vacuumize after passing inert gas.

[0055] Step 2. Take a certain amount of aluminum ingots and aluminum-titanium intermediate alloys, cut them into blocks, put them into the cleaning tank and use the aluminum product oil cleaning solution to clean to remove surface oil and impurities, rinse with 0.2-0.8MPa tap water after cleaning, and then Blow dry with 0.2-0.6MPa compressed air.

[0056] Step 3. Weigh quantitative aluminum ingots and aluminum-titanium intermediate alloys according to the proportion, place them in the crucible of a vacuum stirring furnace, evacuate to 40Pa, heat and melt to obtain an aluminum alloy melt with the composition shown in the table below, and wait for about 50 minutes to completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com