Medical titanium alloy artificial joint precise forging method

An artificial joint and precision forging technology, which is applied in the field of metal forging, can solve the problems of low raw material utilization rate, high die loss, and high production cost, and achieve the effect of increasing raw material utilization rate, small die loss, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

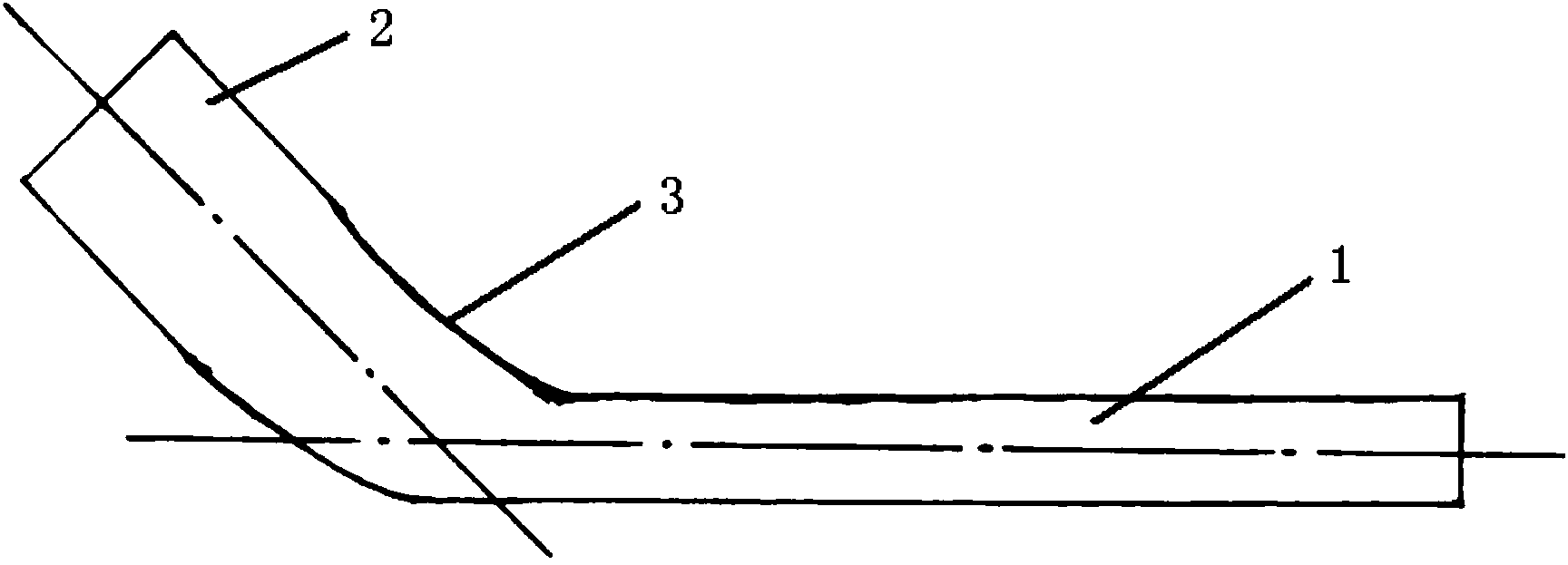

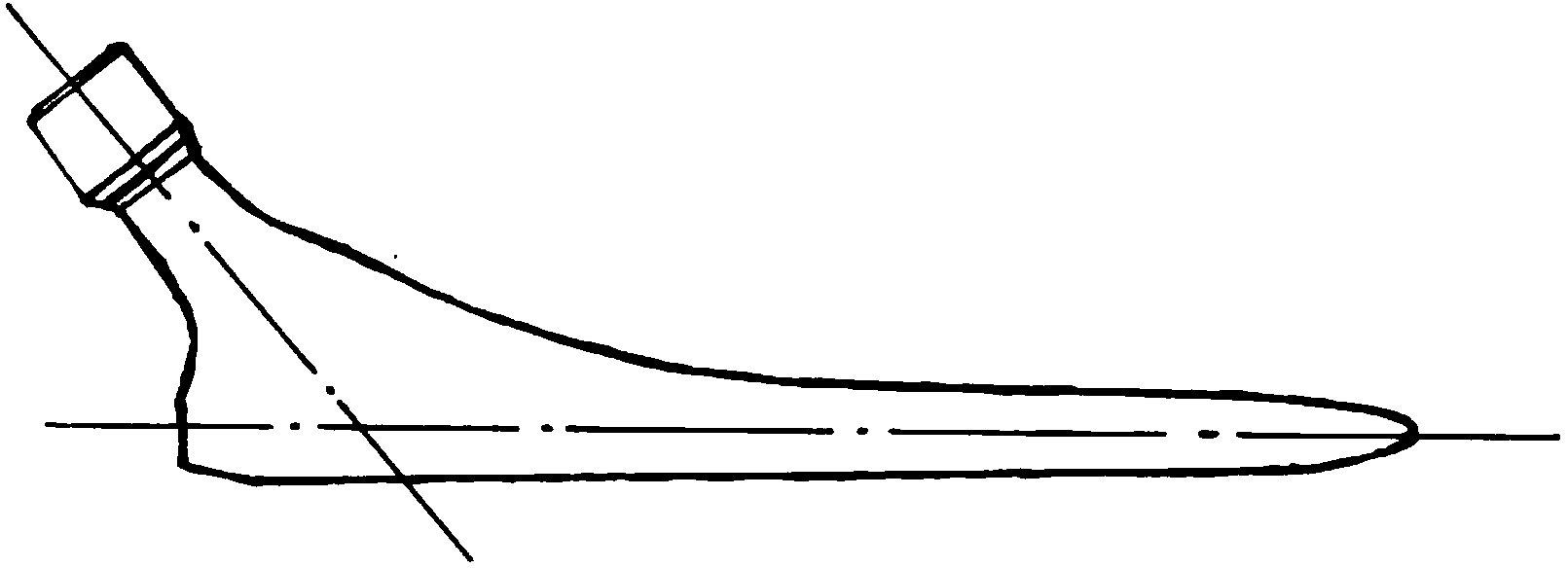

[0024] See attached Figure 1~3 As shown, the method of the present invention will be specifically described below taking the Ti6Al7Nb medical titanium alloy artificial hip joint handle as an example. The steps of this method are:

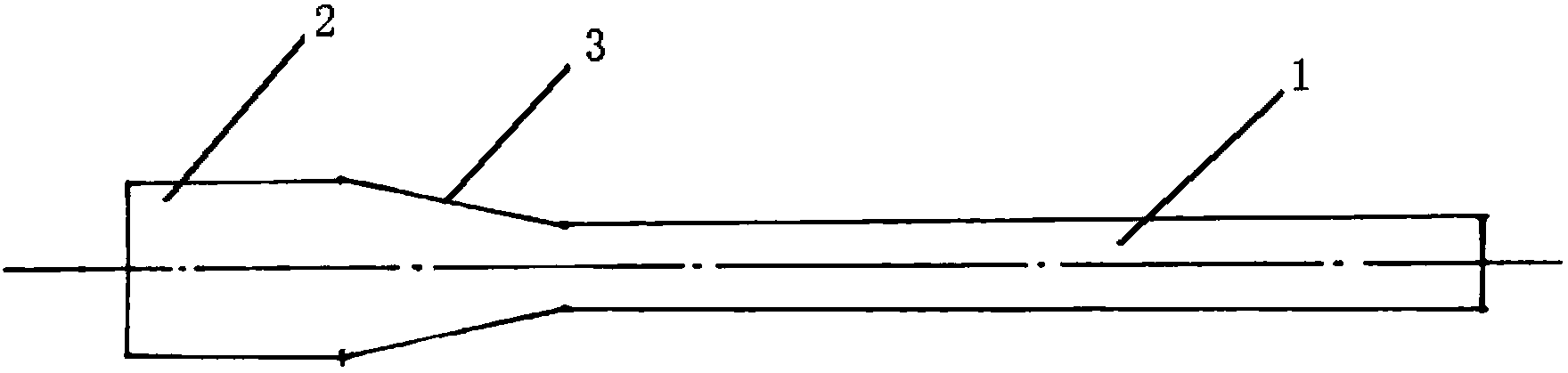

[0025] ⑴Select Φ35mm bar raw material, use lathe or band sawing machine to cut the material, the cutting length is 162±2mm, and make the billet by mechanical processing. The billet is processed from one end into a short diameter section with a length of 105±5mm and a diameter of Φ25mm 1. Starting from the other end, the billet is a long diameter section 2 with a length of 30±2mm to maintain the original bar diameter, and a tapered surface 3 is used to transition between the short diameter section 1 and the long diameter section 2;

[0026] The surface roughness of the blank is required to be 1.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com