Attapulgite-loaded zirconium oxide adsorbent and preparation and detection method thereof

A technology of attapulgite and zirconia, applied in chemical instruments and methods, preparation of test samples, adsorption water/sewage treatment, etc., can solve problems such as weak adsorption, achieve improved stability, fast adsorption speed, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

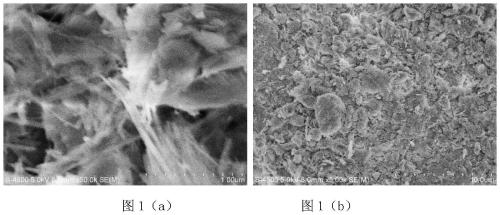

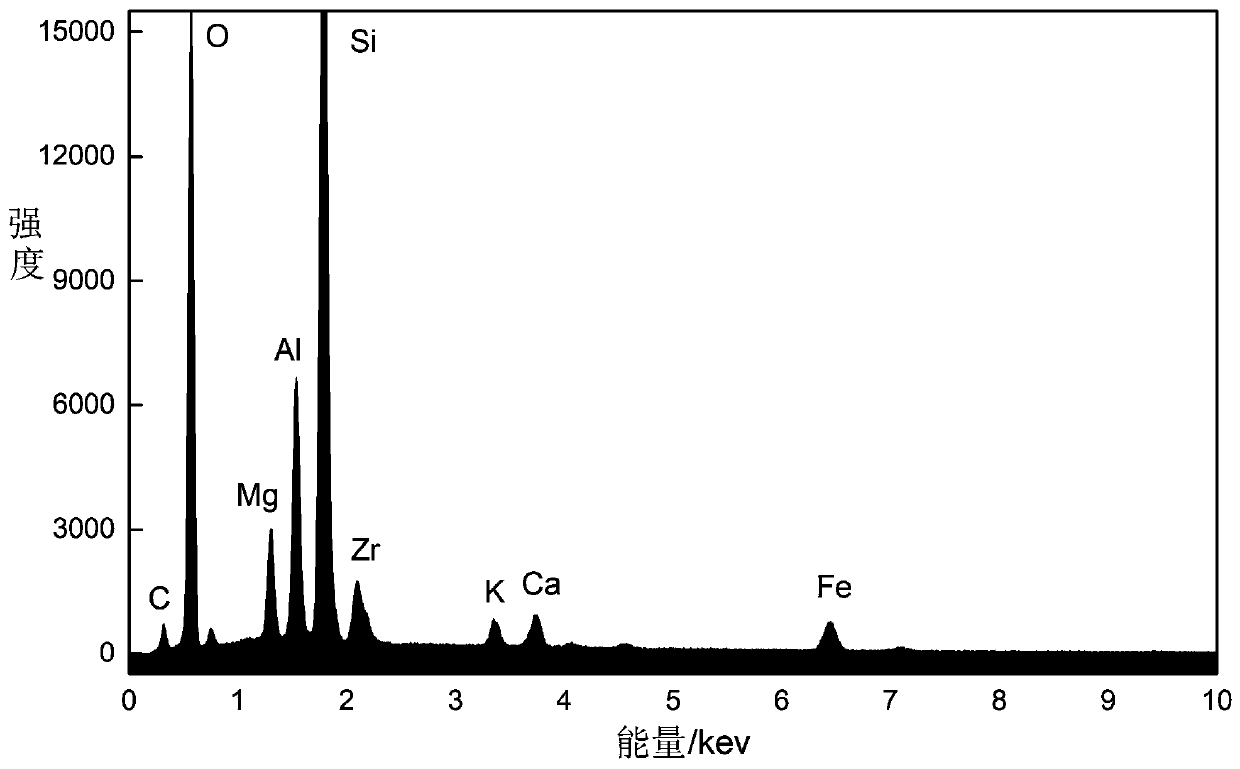

Image

Examples

Embodiment 1

[0038] Implementation example 1: the preparation method of the attapulgite loaded zirconia adsorbent, comprising the following steps:

[0039] 1. Pass the off-white powdery attapulgite through a 400-mesh sieve to obtain fine-grained solids of uniform size.

[0040] 2. Add the attapulgite powder obtained in step 1 into about 100 mL of deionized water, and stir with a hand-held homogenizer until a viscous suspension is formed. Again.

[0041] 3. Add zirconium oxychloride to the suspension obtained in step 2, adjust the pH to about 7.0 with 25% ammonia water while stirring, and the quality of the added zirconium oxychloride is 1 / 8 of the attapulgite.

[0042] 4. Use a hand-held homogenizer to stir the suspension in step 3 at high speed, set the rotation speed to 12500 rpm, and stir for 15 minutes.

[0043] 5. After the stirring in step 4 is completed, let it stand for about 1 hour, pour off the supernatant, and rinse the sediment with 400mL deionized water continuously for 7 da...

Embodiment 2

[0049] Implementation example 2: the adsorption effect of the prepared material

[0050] 1. Prepare As(III) and As(V) aqueous solutions with a concentration of 200ug / L and a volume of 10mL, and add 0.05g of the prepared adsorbent and attapulgite to the prepared As(III) and As(V) respectively. ) aqueous solution, placed in a constant temperature oscillator at 25°C (rotating speed: 160rpm) for 2 hours, then took out the suspension and filtered it with a 0.45 μm filter membrane, and finally measured the concentration of the filtrate with an atomic fluorescence spectrometer.

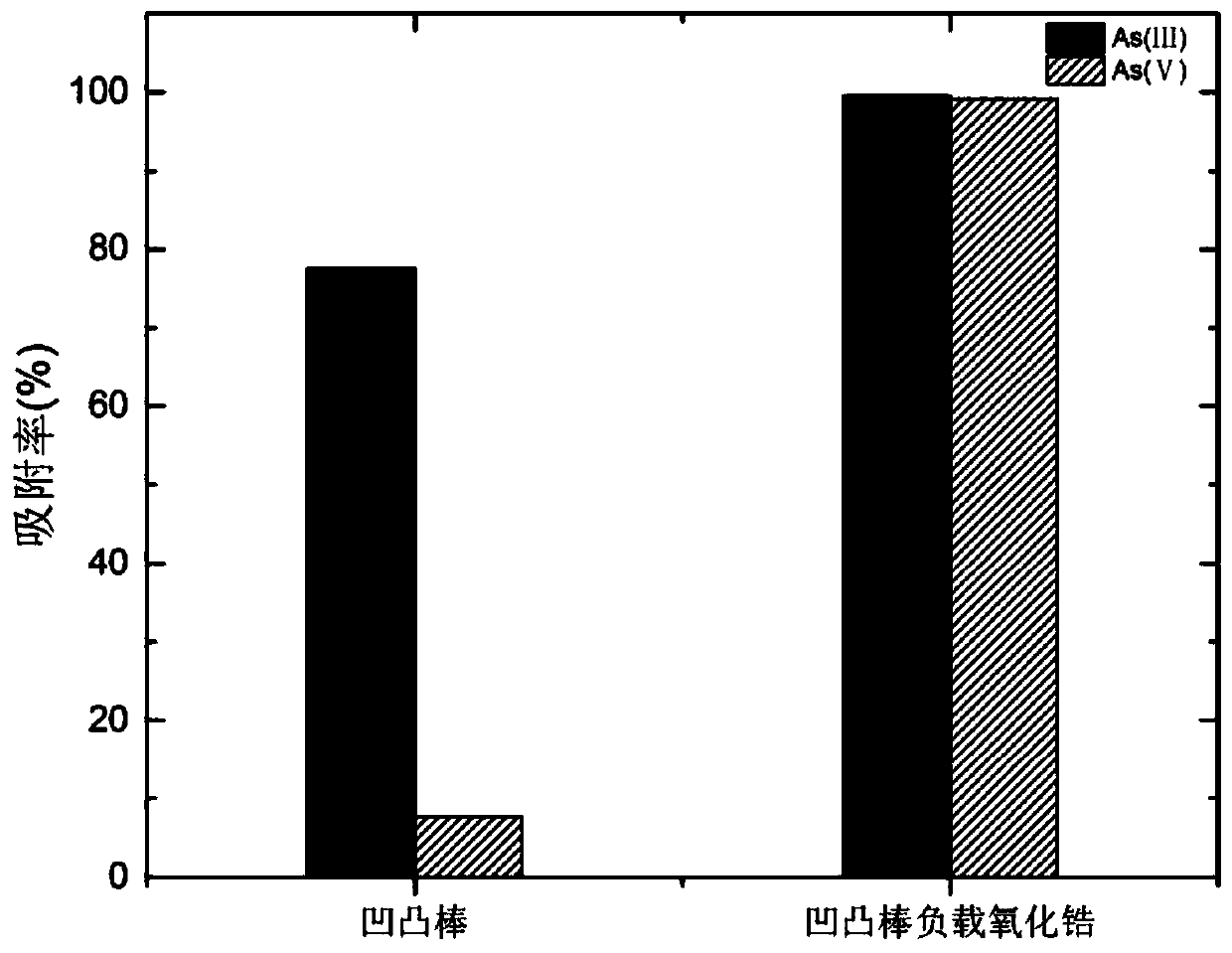

[0051] 2. combine image 3 From the given adsorption rate histogram, it can be seen that the adsorption rate of the attapulgite natural material for As(III) can reach about 75%, while the adsorption rate for As(V) is only 7%. It can be considered that the attapulgite As(V) There is almost no affinity, and the removal rate of the modified adsorbent for As(III) and As(V) is almost 100%, and the adsorption eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com