Preparation method of composite polymer adhesive for permeable pavement

A technology of composite polymer and permeable pavement, which is applied in the field of preparation of composite polymer adhesive for permeable pavement, can solve the problems of poor toughness, low impact strength, easy aging and discoloration of the adhesive, and achieves the improvement of toughness, flexibility and operation. The effect of low requirements and constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

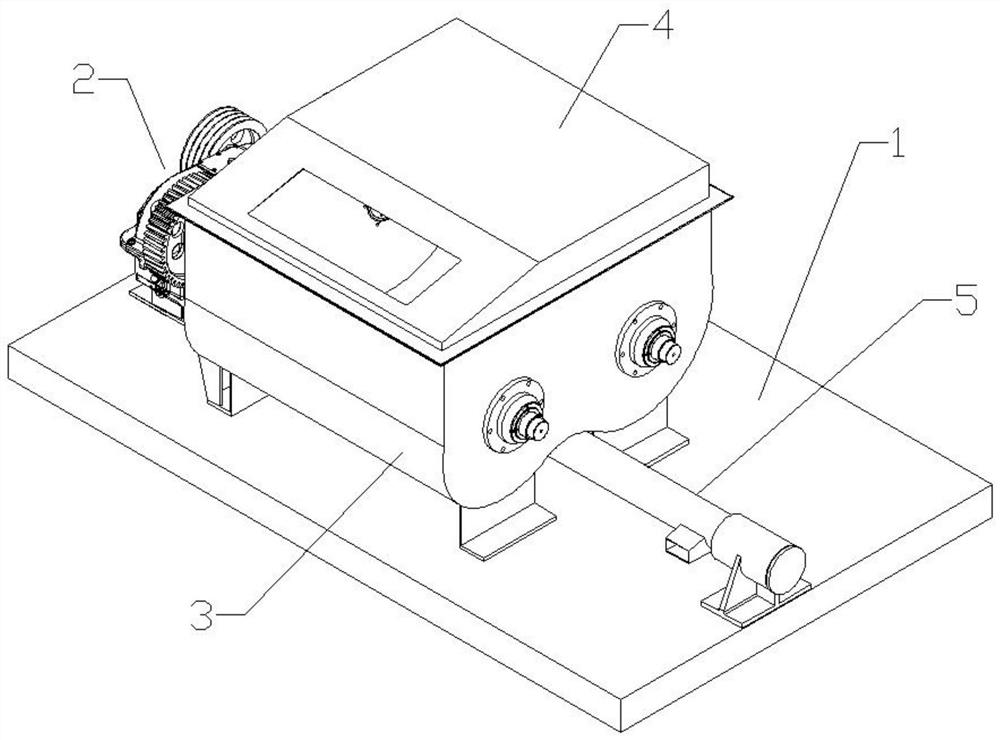

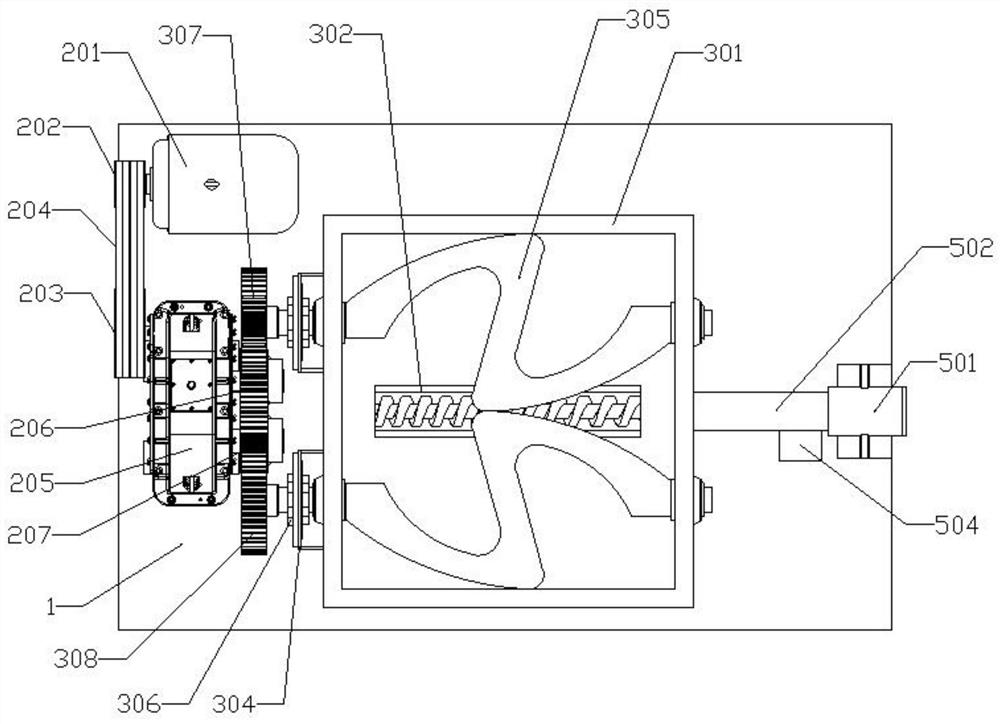

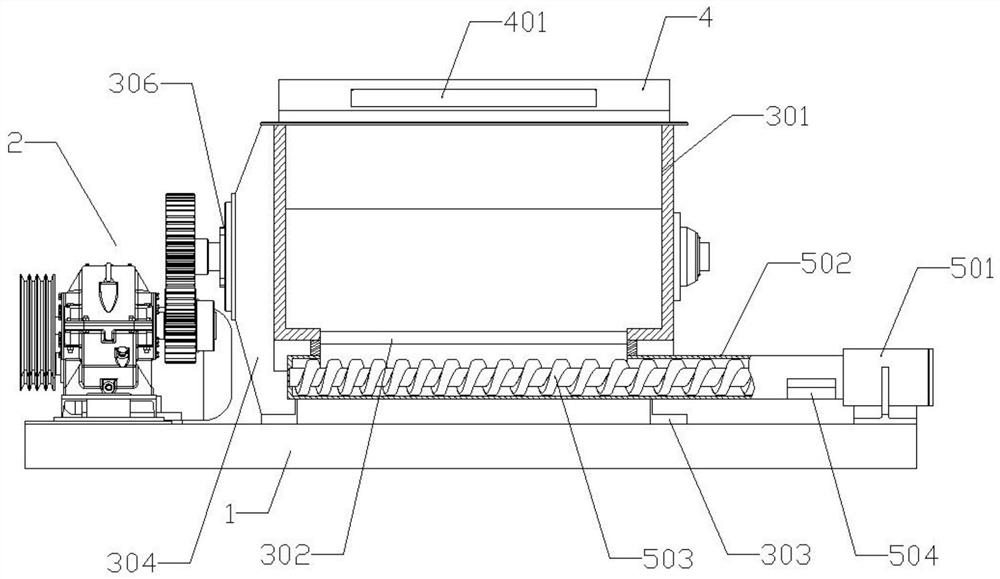

Image

Examples

Embodiment 1

[0034] A method for preparing a composite polymer adhesive for a permeable pavement, specifically comprising the following steps:

[0035] Step S1, put 90 parts by weight of resin base material, 6 parts by weight of reactive diluent, 10 parts by weight of carboxy-terminated nitrile rubber, 3 parts by weight of styrenated phenol and 0.1 part by weight of ultraviolet absorber, all into In the stirring tank, under the conditions of rotating speed of 1000r / min and temperature of 25°C, stirring for 20min to obtain the first mixture;

[0036] Step S2, put 75 parts by weight of modified amine curing agent, 2 parts by weight of accelerator and 3 parts by weight of auxiliary curing agent piperazine into a stirring tank at a speed of 600r / min and a temperature of 30°C Under conditions, stir for 20min to get the second mixture;

[0037] Step S3, add the uniformly stirred first mixture and the second mixture into the glue making box 301 of the mixing glue making equipment according to th...

Embodiment 2

[0044] A method for preparing a composite polymer adhesive for a permeable pavement, specifically comprising the following steps:

[0045] Step S1, put 95 parts by weight of resin base material, 10 parts by weight of reactive diluent, 15 parts by weight of carboxy-terminated nitrile rubber, 4 parts by weight of styrenated phenol and 0.3 parts by weight of ultraviolet absorber, all into In the stirring tank, under the conditions of rotating speed of 1100r / min and temperature of 30°C, stirring for 25min to obtain the first mixture;

[0046] Step S2, put 82 parts by weight of modified amine curing agent, 4 parts by weight of accelerator and 4 parts by weight of auxiliary curing agent piperazine into a stirring tank at a speed of 700r / min and a temperature of 32°C Under the condition, stir 25min, obtain the second mixture;

[0047] Step S3, add the uniformly stirred first mixture and the second mixture into the glue making box 301 of the mixing glue making equipment according to ...

Embodiment 3

[0054] A method for preparing a composite polymer adhesive for a permeable pavement, specifically comprising the following steps:

[0055] Step S1, put 100 parts by weight of resin base material, 12 parts by weight of reactive diluent, 20 parts by weight of carboxy-terminated nitrile rubber, 6 parts by weight of styrenated phenol and 0.5 parts by weight of ultraviolet absorber, all into In the stirring tank, under the conditions of rotating speed of 1200r / min and temperature of 35°C, stirring for 30min to obtain the first mixture;

[0056] Step S2, put 90 parts by weight of modified amine curing agent, 5 parts by weight of accelerator and 5 parts by weight of auxiliary curing agent piperazine into a stirring tank at a speed of 800r / min and a temperature of 35°C Under the condition, stir 30min, obtain the second mixture;

[0057] Step S3, add the uniformly stirred first mixture and the second mixture into the glue making box 301 of the mixing glue making equipment according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com