Preparation mold and preparation method of integrated composite material spray pipe

A composite material and mold technology, which is applied in the field of mold and preparation of integrated composite material nozzles, can solve problems such as product porosity, impact on product quality, and pressure on the inner surface of the product, so as to reduce the generation of polyglue lines , improve the anti-ablation performance, and increase the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

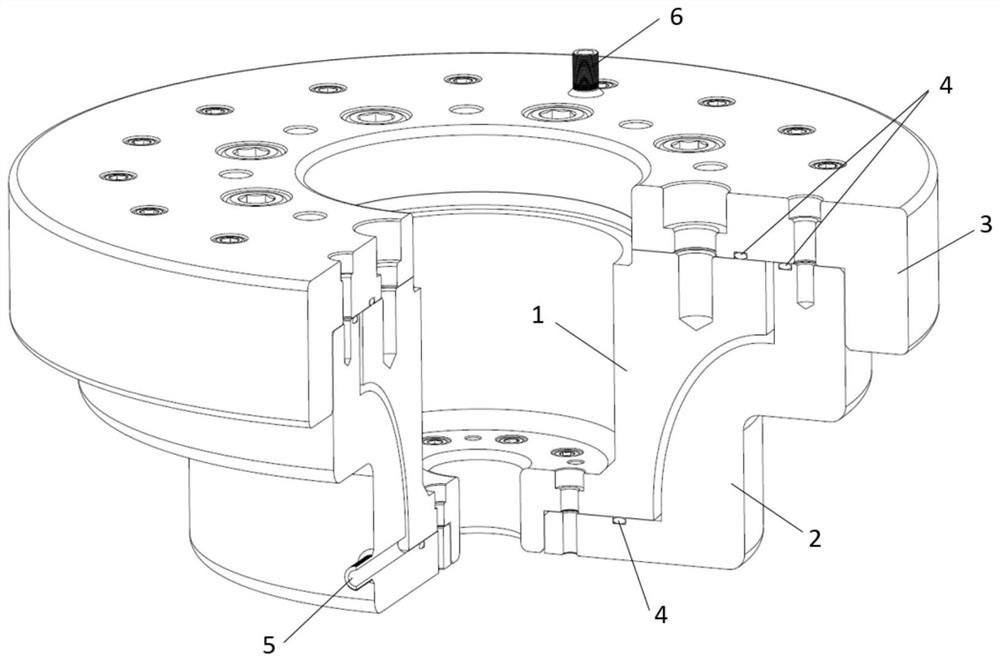

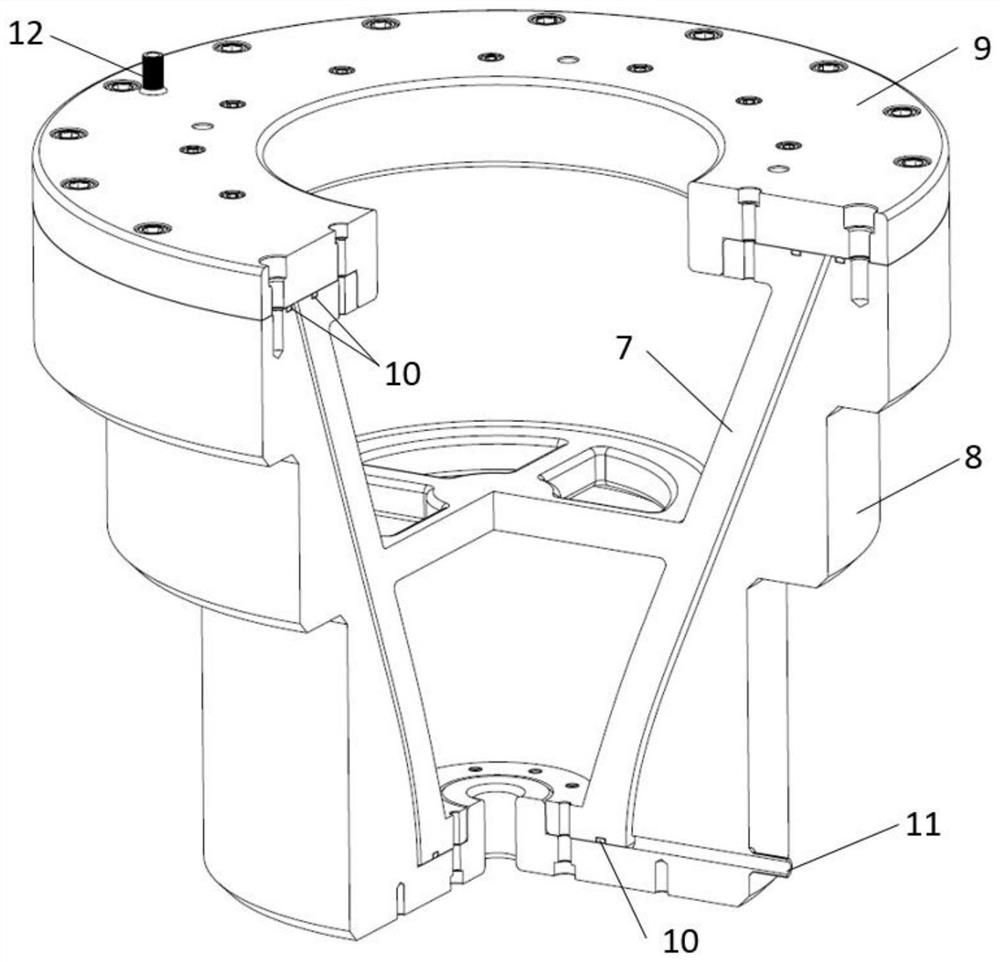

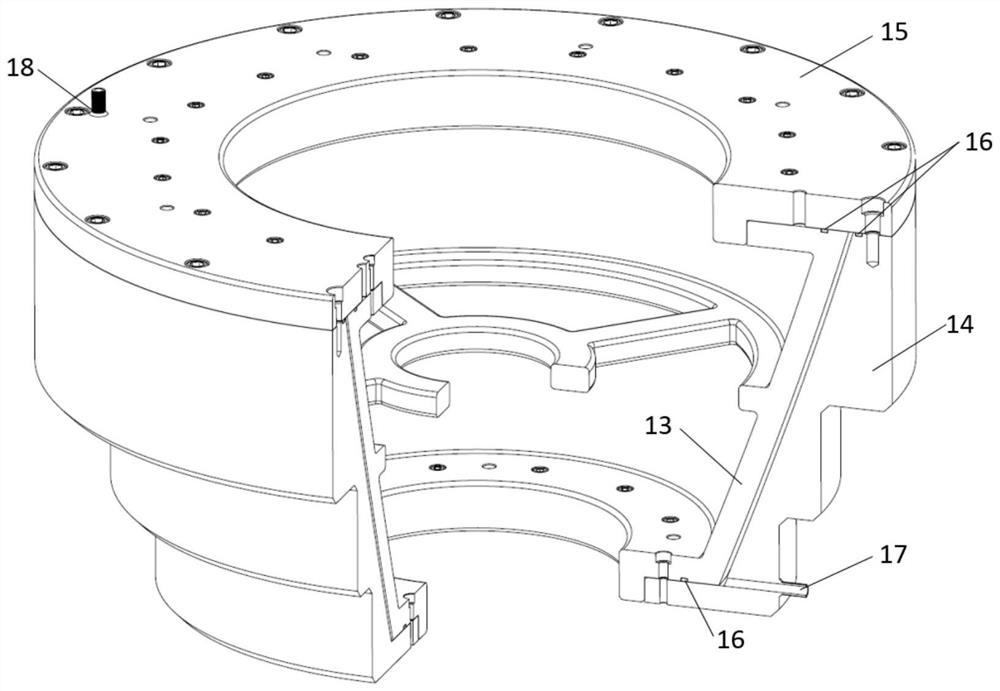

[0081] The preparation mold of the integrated composite material nozzle includes: the first expansion layer preparation mold of the core mold and the expansion layer preparation mold for the tail section of the core mold detachably connected with it, and the first expansion layer preparation mold of the core mold includes: the first section of the core mold 1, The outer mold of the first section of the mandrel 2, the upper flange of the first section of the mandrel 3, the rubber sealing ring 4, the injection hole of the first section of the expansion layer 5, the air hole 6 prepared for the first section of the expansion layer, and one end of the first section of the mandrel 1 is a truncated circular structure And gradually extend the transition to the cylindrical structure, so that the other end of the first section 1 of the core mold is a cylindrical structure, the two ends of the first section 1 of the core mold have openings, and the interior has a housing cavity, and the ou...

Embodiment

[0110] In this embodiment, the axial length of the winding mandrel of the integrated composite material nozzle preparation mold is 1450 mm, the weight is 1058 kg, and the thickness of the expansion layer is 4 mm. The inner diameter of the inlet of the integrated composite nozzle prepared in this example is The inner diameter of the outlet is The integrated composite nozzle is prepared by a method comprising the following steps:

[0111] S1. Perform sandblasting on the outer surface of the first section 1 of the core mold; the upper cone 7 of the tail section of the mandrel; the middle cone 13 of the tail section of the mandrel; the lower cone 19 of the tail section of the mandrel, and the sandblasting specification is 20 mesh;

[0112] S2. Prepare the mold by assembling the expansion layer of the first section of the mandrel, including: the first section of the mandrel 1 , the outer mold 2 of the first section of the mandrel, the upper flange 3 of the first section of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com