Two-piece type hard sealing floating ball valve

A floating ball valve, hard sealing technology, applied in shaft sealing, valve details, valve device and other directions, can solve problems such as poor valve sealing effect, and achieve the effect of improving sealing, convenient installation and avoiding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

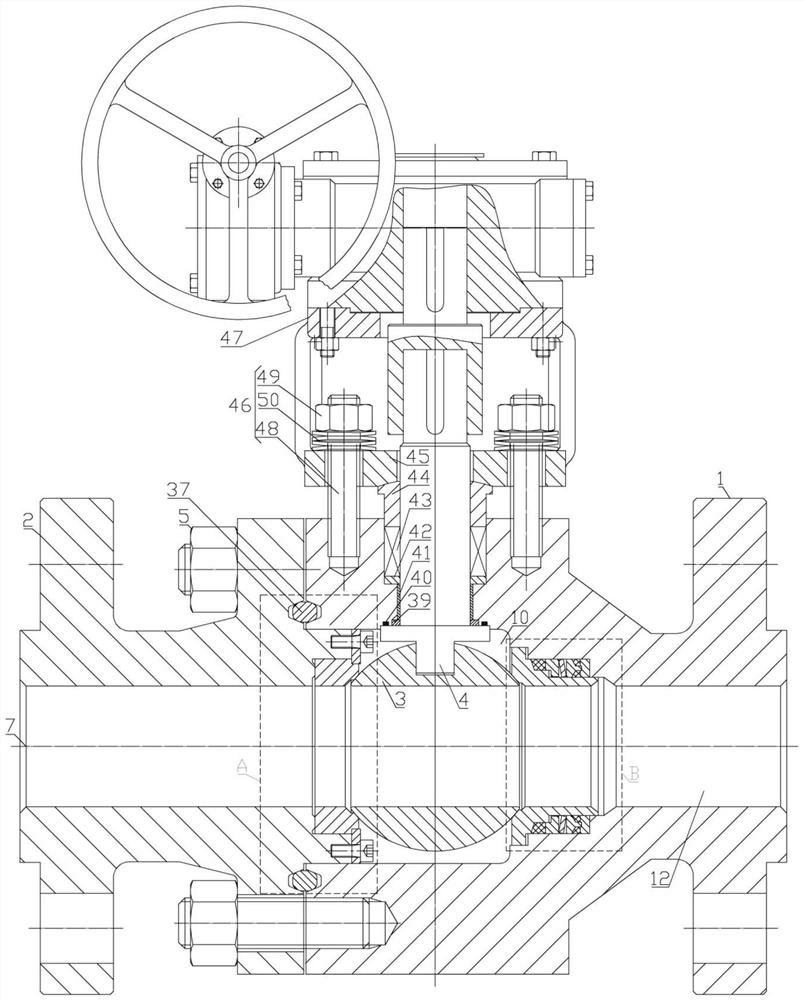

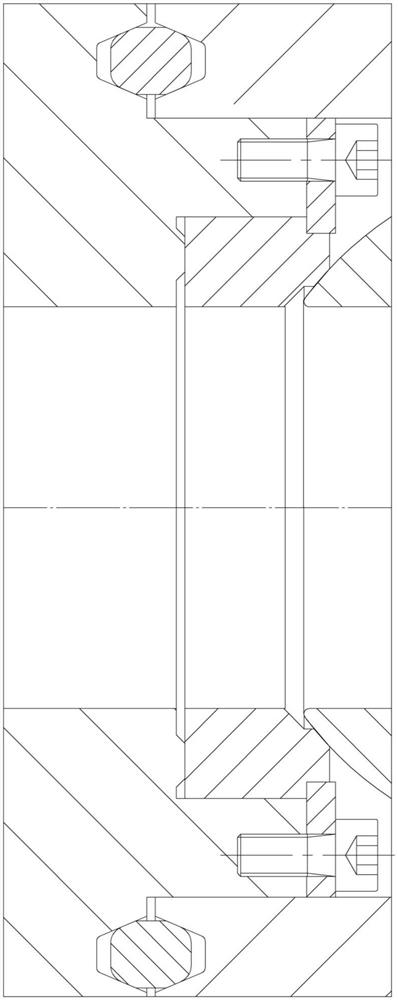

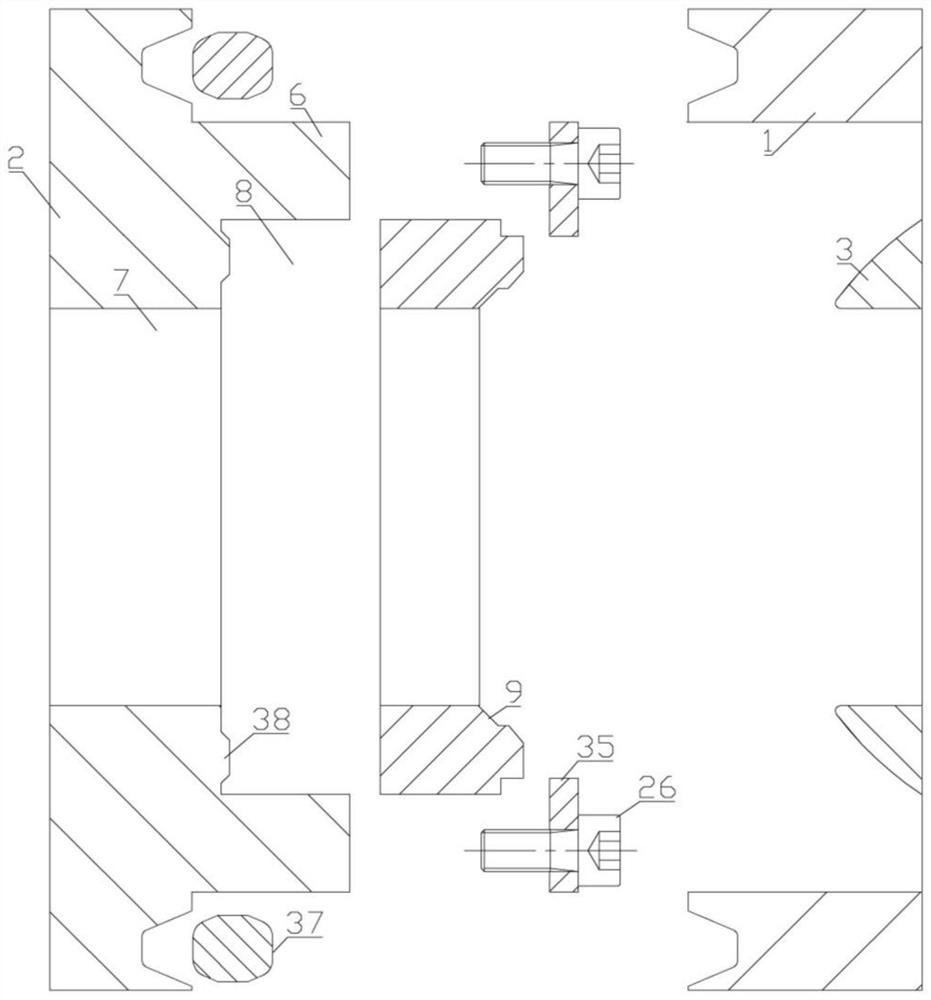

[0023] combined with Figure 1-5 , this embodiment provides a two-piece hard-sealed floating ball valve, including a valve body 1, a valve cover 2, a ball 3 and a valve stem 4, etc., wherein the valve body 1 and the valve cover 2 are obtained by forging process, avoiding the traditional There are defects such as bubbles in the casting. Secondly, in this embodiment, the valve body 1 and the valve cover 2 are arranged horizontally, that is, the valve cover 2 is provided on one side of the valve body 1, and the valve cover 2 faces the side wall of the valve body 1 and the valve body. The side wall of the body 1 facing the valve cover 2 is a vertical wall, and the adjacent ends of the two are connected by a connecting bolt group 5. Secondly, in order to effectively seal the gap between the two, in this embodiment, the valve body 1 An octagonal gasket 37 is also provided between the valve cover 2, and a half-embedded groove is respectively provided on the side wall of the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com