Refiring method of imitating Song Junguan porcelain based on nano-iron oxide glaze and firing series of imitating Song Junguan porcelain

A nano-iron oxide and iron oxide glaze technology, applied in the field of ceramics, can solve problems such as chroma and texture that are far from the quality of Song Jun official porcelain, and achieve improved firing efficiency, uniform color and color transition, and uniform color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Experimental preparation: The traditional pottery is drawn with commonly used pottery clay, then fired at a high temperature of 1000°C to make pottery, and naturally cooled in a kiln to obtain a green body. Preparation of raw materials for glaze: sort hard raw materials such as feldspar, quartz, and calcite used locally in Yuzhou-coarse crushing (with jaw crusher)-medium fine crushing (wheel mill) for later use; calcined bovine bone and talc for medium fine crushing spare.

[0066] Basic glaze preparation method: in mass percentage, 65% feldspar, 15% quartz, 15% calcite, 5% calcined talc are mixed, add the nano iron oxide of total mass 0.5% additionally (particle diameter is 30 nanometers, and purity is 99.9 %, provided by Shanghai Shuitian Material Technology Co., Ltd.), mixed evenly to obtain a mixed glaze. The basic glaze raw materials are provided by Dasong Guanyao Porcelain Industry Co., Ltd. (see attached table 1).

[0067] According to the mass ratio of mixed g...

Embodiment 2

[0070] 1. Experimental preparation: with embodiment 1.

[0071] 2. In mass percentage, mix 65% feldspar, 15% quartz, 15% calcite, 5% calcined talc, plus 1.0% nano-iron oxide with a total mass of 1.0%, and mix them evenly.

[0072] 3. According to the mass ratio of mixed glaze: ball: water = 1:1.5:0.7, add ball mill, wet ball mill processing, the glaze fineness is over 180 mesh sieve and the balance is less than 0.06wt%, and the water content of the glaze slurry is controlled at 45% by weight. The calcined green body is glazed by dipping the glaze, and the thickness is controlled at about 1mm. After drying, it is fired in a kiln (same as Example 1), and cooled naturally to obtain azure Jun porcelain ( diagram 2-1 ,2-2).

[0073] 4. Summary: The color of the obtained utensils is azure, and the color is uniform. The results of the spectrophotometer show that the color difference (△E value) is only 0.38, which is very close to the Song Jun official kiln porcelain (04Y98) ( Fi...

Embodiment 3

[0075] 1. Experimental preparation: with embodiment 1.

[0076] 2. Mix 65% feldspar, 15% quartz, 15% calcite, 5% calcined talc, and 1.5% nano-iron oxide with a total mass of 1.5% by mass percentage.

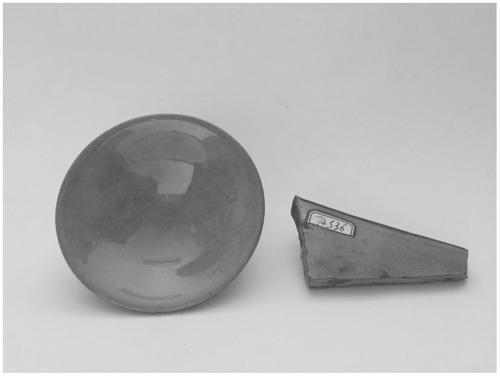

[0077] 3. According to the mass ratio of mixed glaze: ball: water = 1:1.5:0.7, add ball mill, wet ball mill processing, the glaze fineness is over 180 mesh sieve and the balance is less than 0.06wt%, and the water content of the glaze slurry is controlled at 45% by weight. The calcined green body is glazed by dipping the glaze, and the thickness is controlled at about 1mm. After drying, it is fired in a kiln (same as in Example 1), cooled naturally to obtain sky blue Jun porcelain ( Figure 3-1 , 3-2).

[0078] 4. Summary: The color of the obtained utensils is sky blue, and the color is uniform. The results of the spectrophotometer show that the color difference (△E value) is only 0.05, which is very close to the Song Jun official kiln porcelain (74S71) ( Figure 3-3 ), especi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com