Mould melting-deposition forming and laser impact forging composite additive manufacturing method and device

A technology of laser shock and additive manufacturing, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement, to achieve the effects of avoiding thermal stress, improving forming quality and efficiency, and avoiding air holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

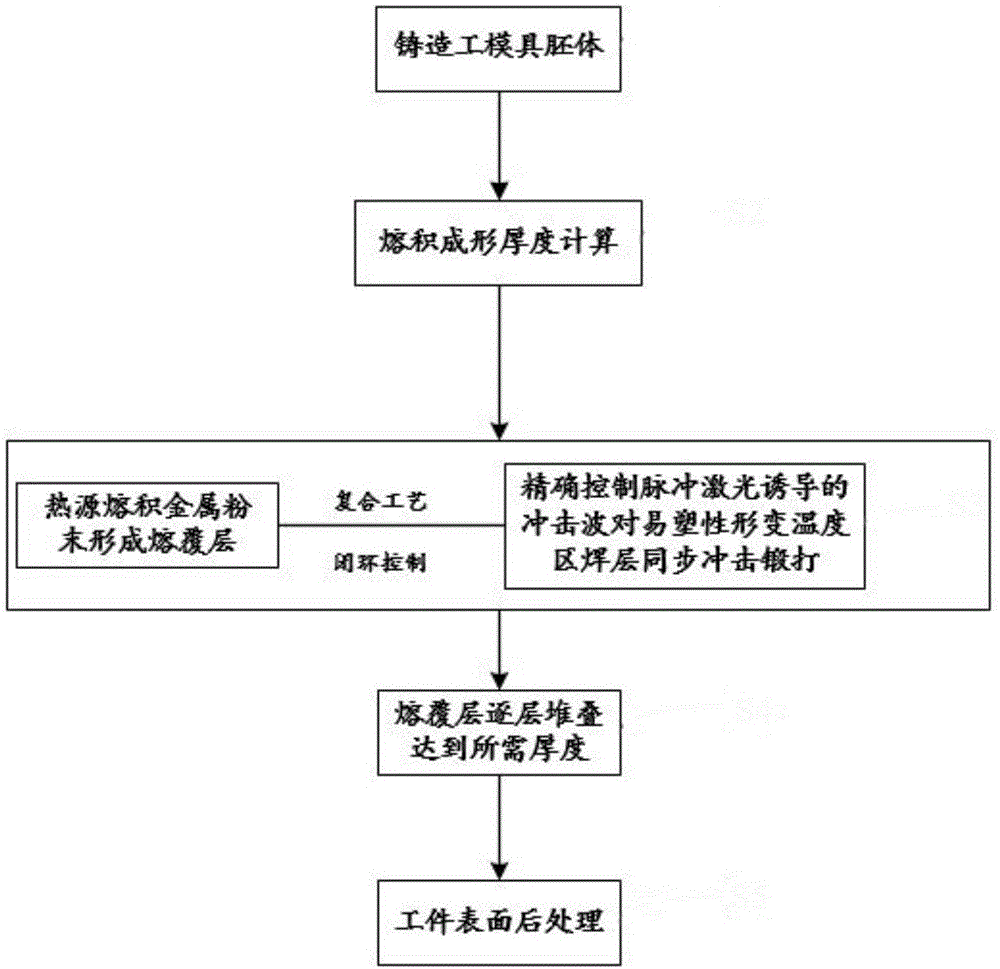

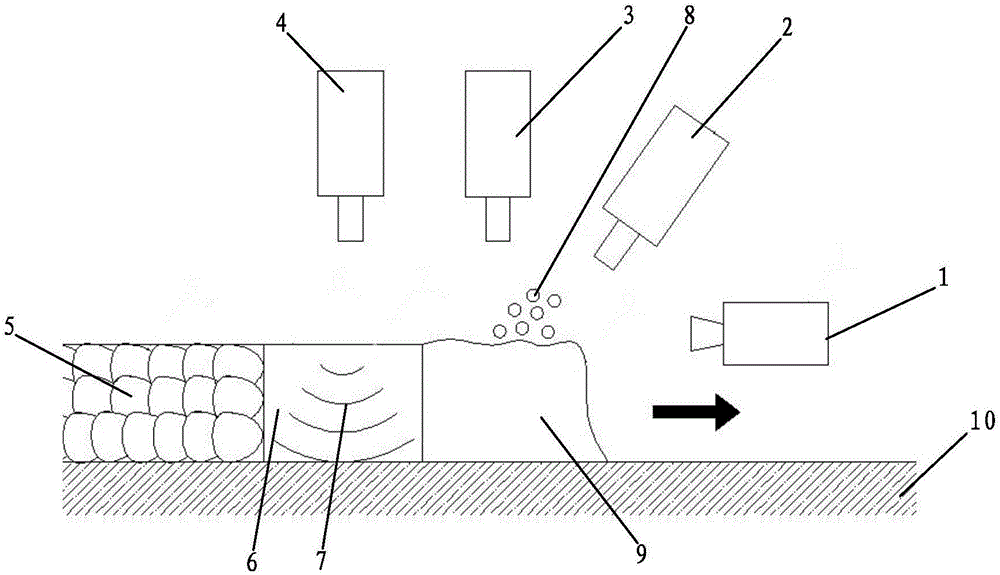

[0034] refer to figure 1 with figure 2 , this embodiment relates to a manufacturing method for laser shock forging of die fusion deposition forming, comprising the following steps:

[0035] 1) casting mold blank;

[0036] 2) Calculation of deposition forming thickness;

[0037] Measure the size of the cast blank, and calculate the difference between the two according to the required mold size, which is used as the thickness value of the cladding layer to be increased;

[0038]3) The cladding layer is formed by depositing metal powder through the heat source, and at the same time, the temperature of the deposited metal area of the cladding layer is collected by the temperature sensor, and the collected data is sent to the controller, which controls the laser generator to control the Synchronous impact forging is carried out in the deposited metal area of plastic deformation temperature; the cladding layer is stacked layer by layer until the cladding layer reaches the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com