Shade assembly for a transparent bodywork surface of a vehicle

A sunshade and component technology, applied in the field of sunshade components, can solve the problems of increased manufacturing cost, complex mechanism, expensive, etc., and achieve the effect of reduced manufacturing cost and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

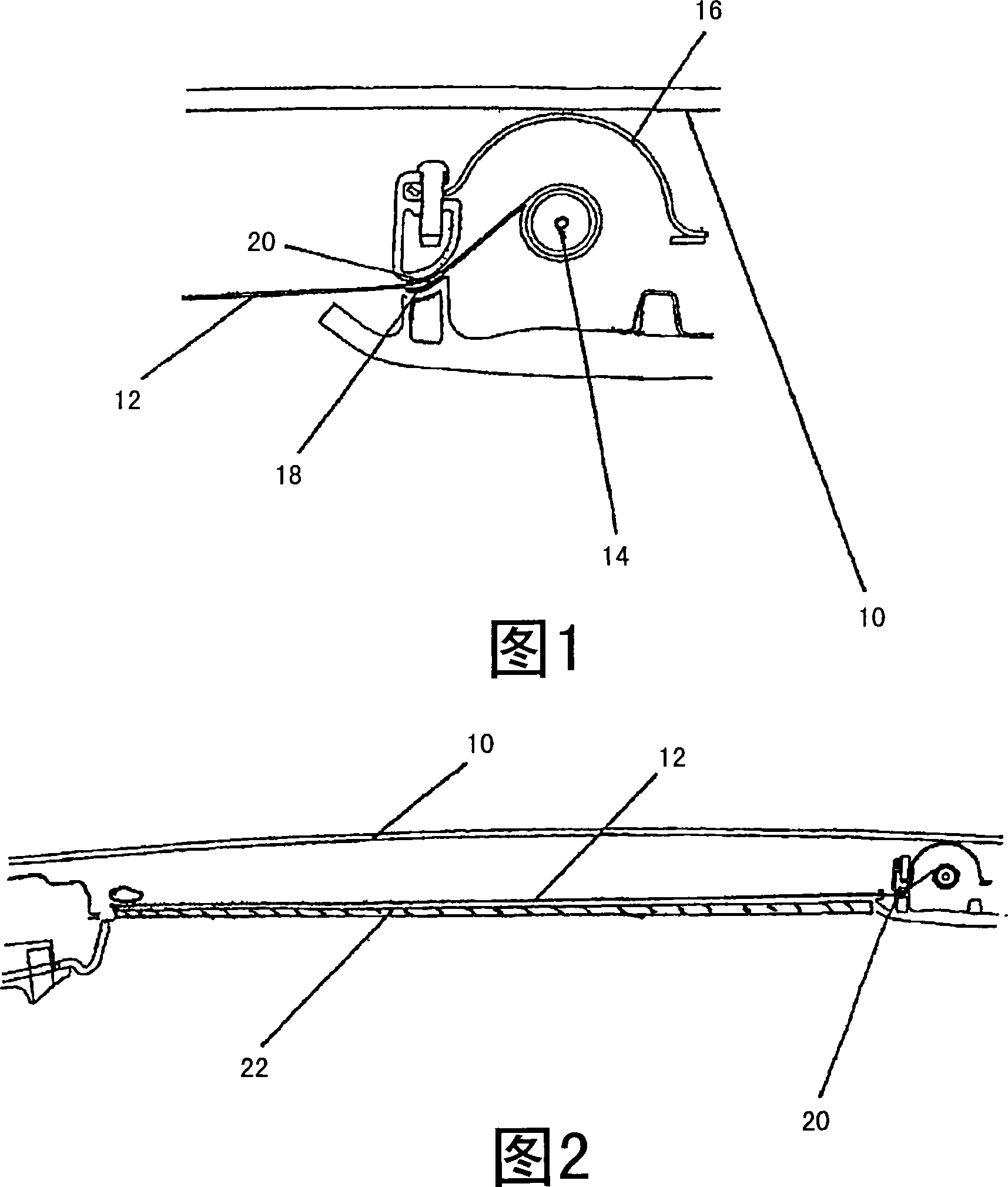

[0026] Fig. 1 shows a transparent body surface of a vehicle in the form of a glass sheet 10 in a cross-sectional view through the roof area of the motor vehicle. The light shield assembly has a roller blind 12 designed as an LCD film whose light transmittance can be changed by applying a voltage, thereby shielding the interior of the vehicle from incident light through the glass plate 10. The roller blind 12 is installed so that it can be wound and unrolled using the winding shaft 14. The voltage supply to the roller blind 12 may be provided through a loop contact (not shown) of the winding shaft 14. The roller blind 12 is guided away from the winding shaft 14 by a gap 20 which is lined with a felt strip 18 on both sides. The dimensions of the gap 20 and the two felt belts 18 are such that the roller blind 12 can pass through the gap without applying any large additional force, but on the other hand, the corresponding felt belts 18 are on both sides of the gap. In such a way, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com