Flat plate type solid oxide fuel battery stack device

A fuel cell stack and solid oxide technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as battery performance attenuation, seal failure, electrolyte rupture, etc., to reduce energy and improve gas Tightness, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

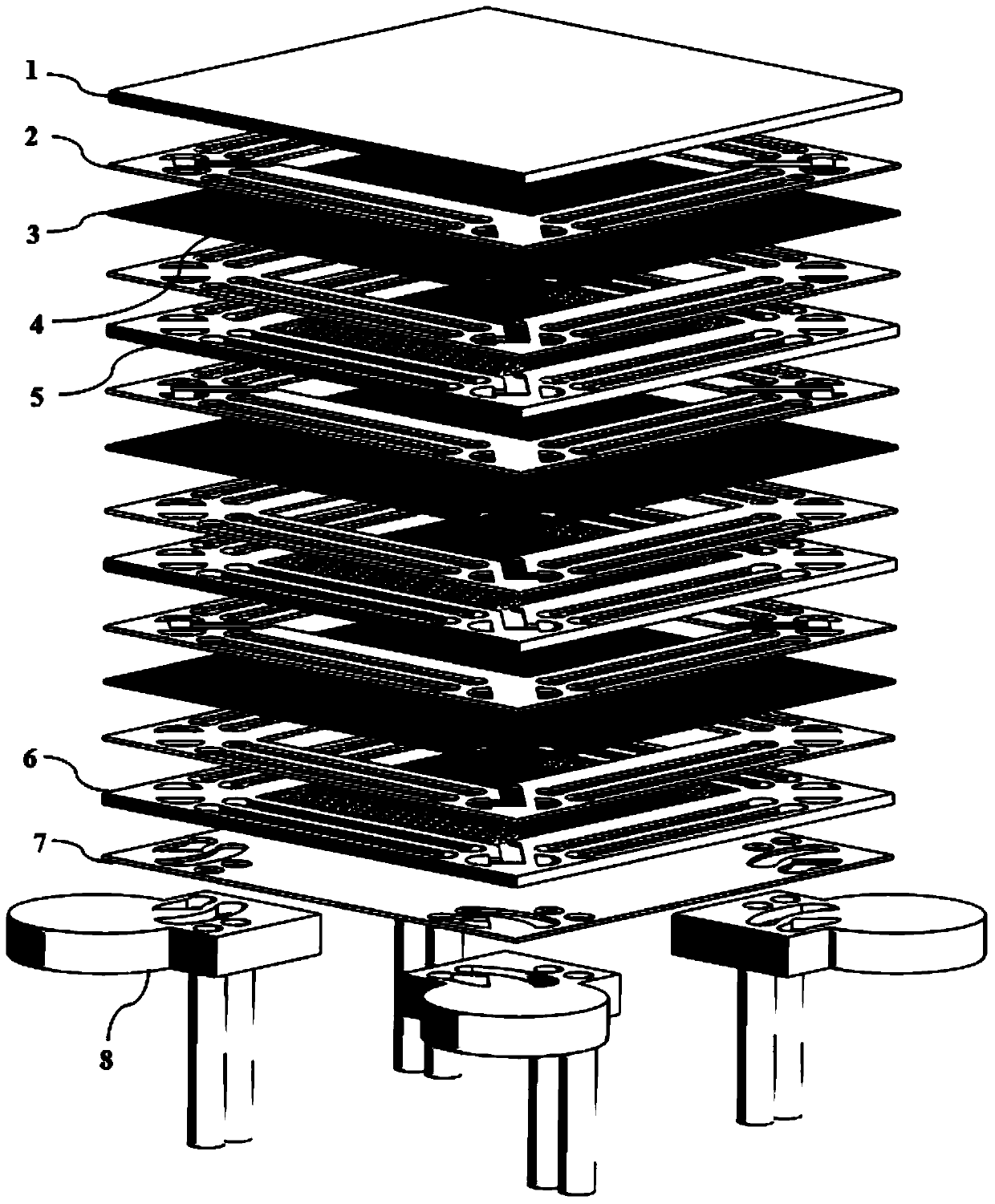

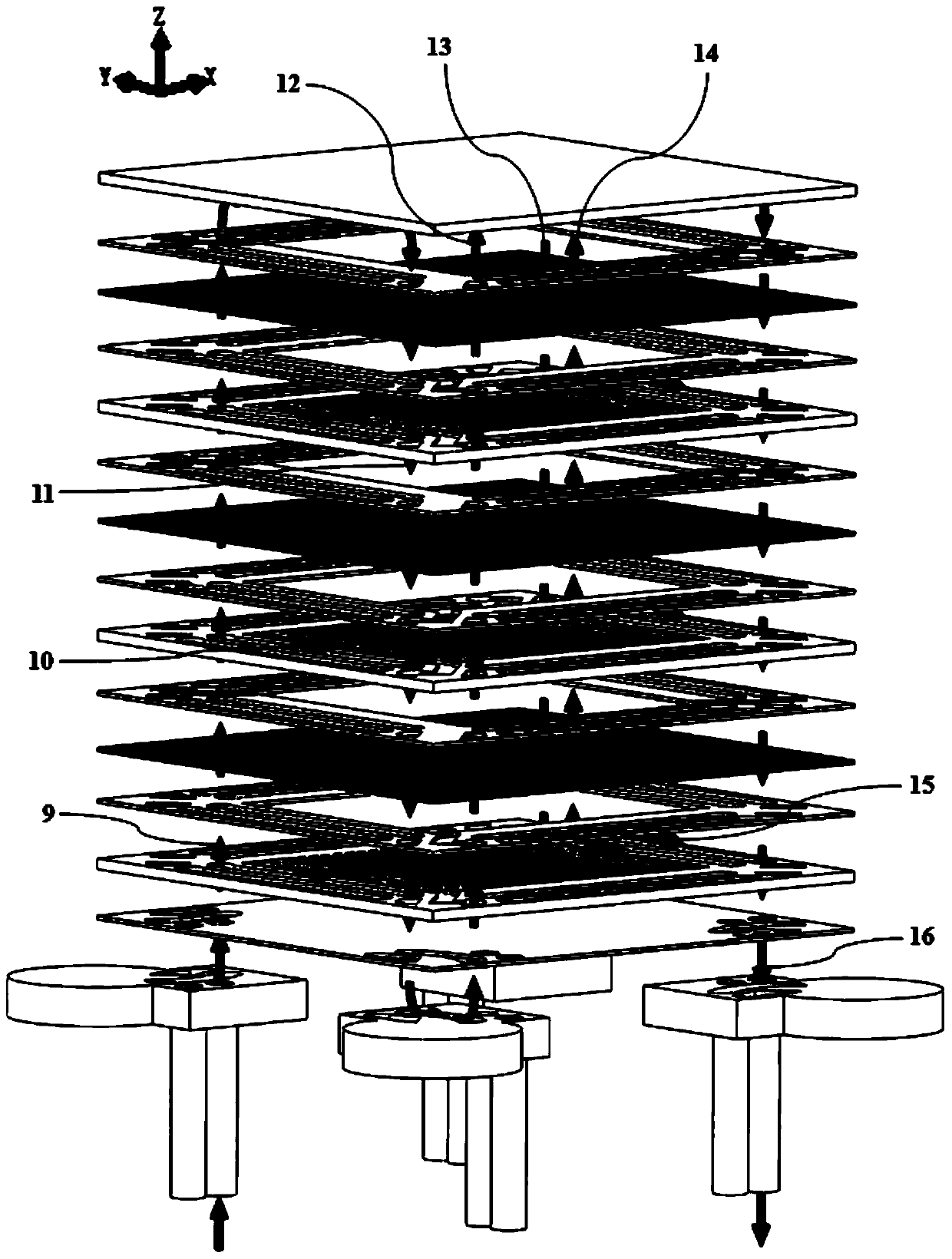

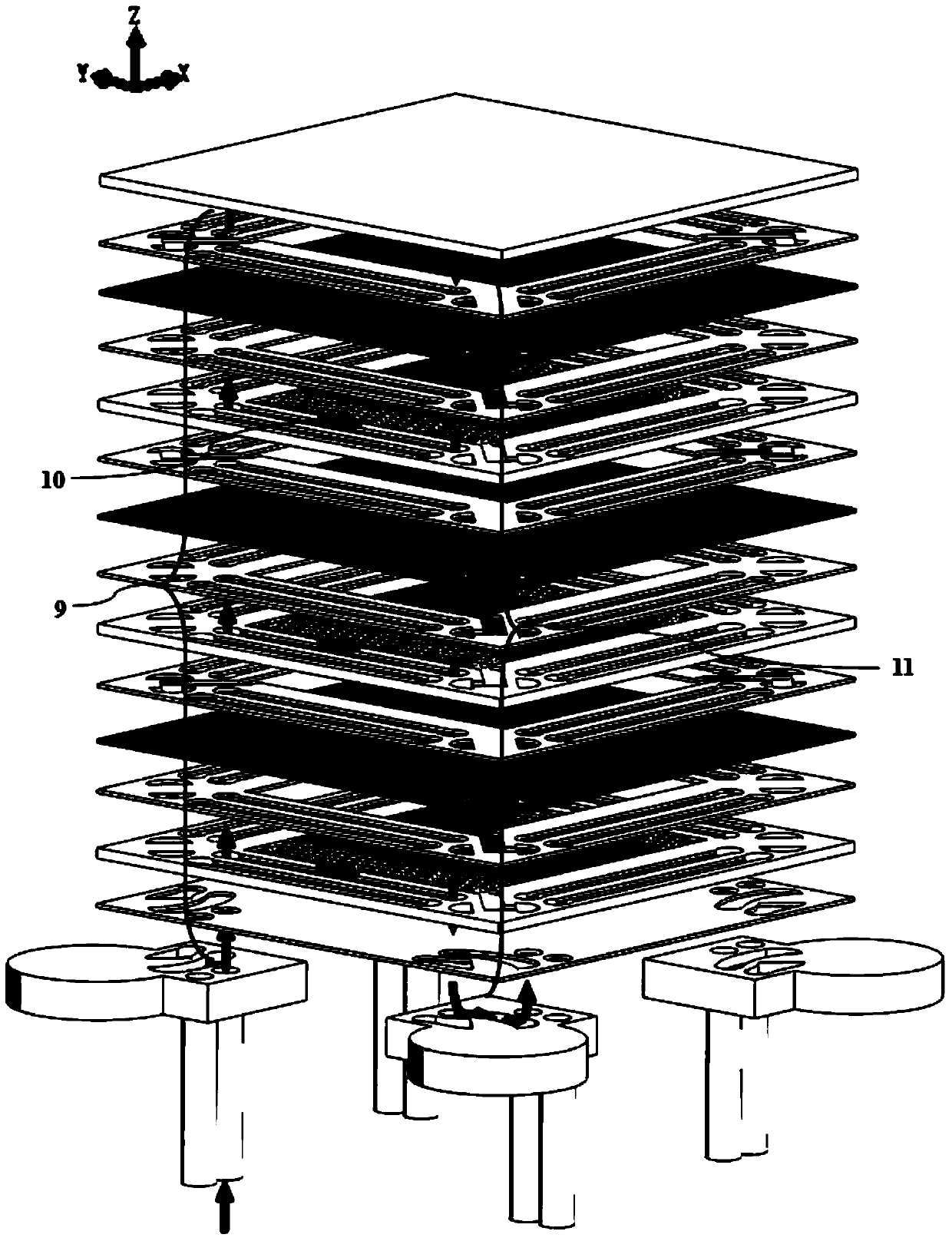

[0032] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] Such as Figure 1 to Figure 7 As shown, a flat solid oxide fuel cell stack device of the present invention is sequentially installed with a base 8, a base seal 7, a bottom plate 6 and a top plate 1 from bottom to top, and several groups of The battery stacks are stacked up and down. Each battery stack is stacked with a seal 2, a single cell frame 3, a seal 2 and a connector 5 from top to bottom. The single cell frame 3 is provided with a single The battery 4, the four corners of the base 8, the base seal 7, the bottom plate 6, the connecting body 5, the cell frame 3 and the seal 2 are provided with two holes, and because the base 8, the base seal 7 , bottom plate 6, connecting body 5, single cell frame 3 and sealing member 2 are stacked up and down, and the eight holes in each layer are correspondingly connected up and down to form eig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com