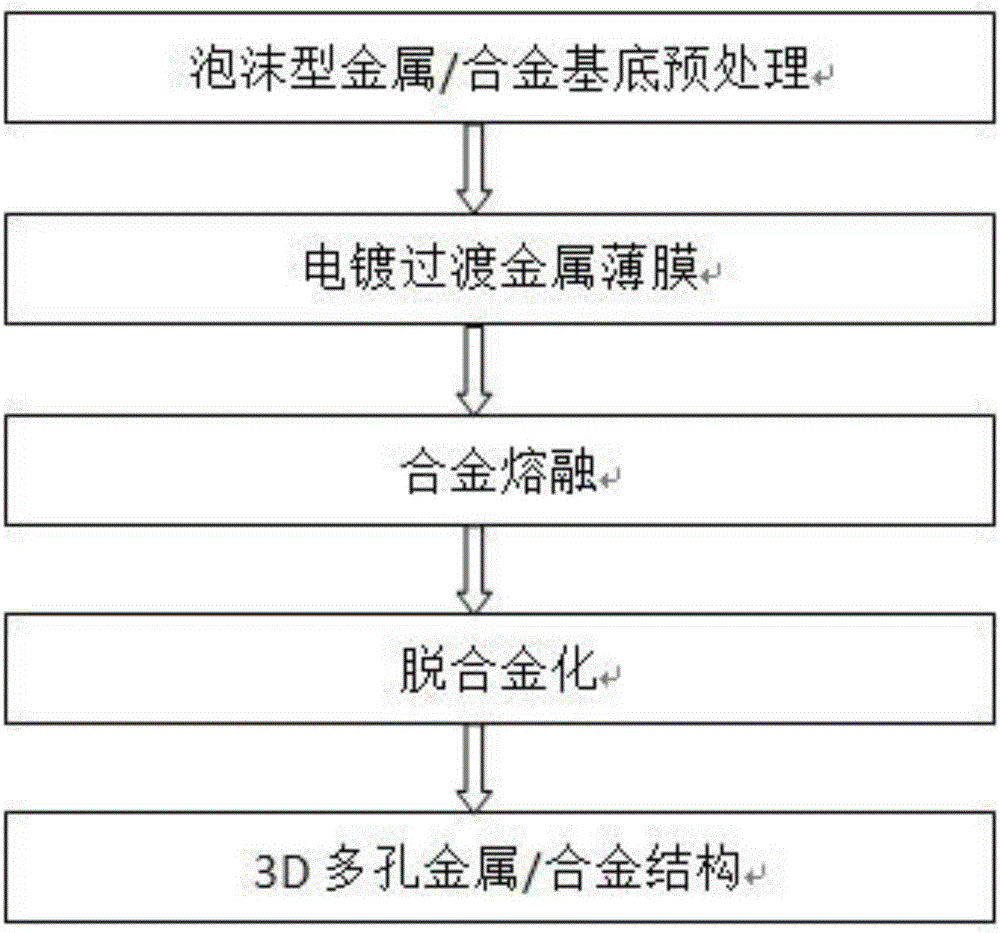

Preparation method for 3D nano porous metal materials

A nanoporous, metal technology, applied in the field of preparation of 3D nanoporous metal materials, can solve the problems that cannot be used to prepare large-sized bulk materials, and the strength of metal materials is poor, so as to avoid thermal stress and interlayer thermal diffusion, Avoid pollution, the effect of uniform and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

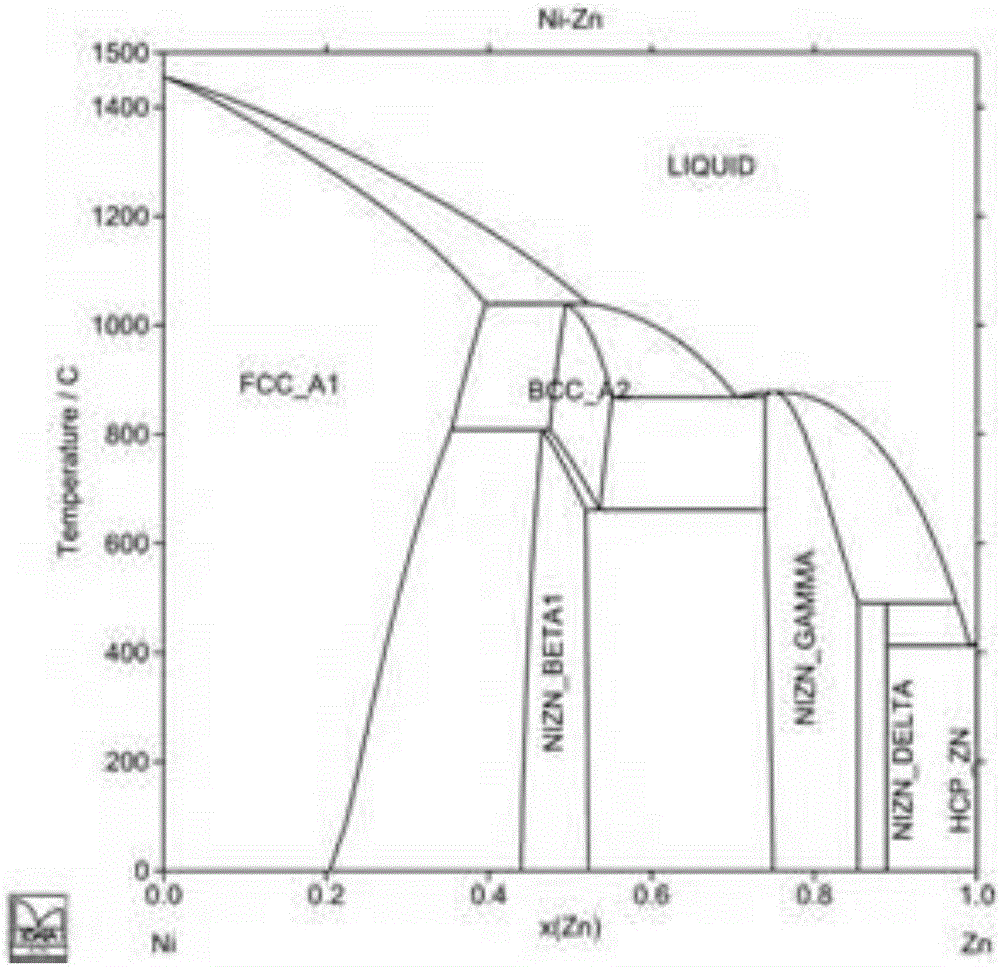

[0038] Example 1: Preparation of nanoporous nickel material.

[0039] Step 1, substrate pretreatment is performed on the foamed Ni.

[0040] 1a) Commercially purchased Ni foam was pressed into thin slices, polished and polished, then ultrasonically cleaned with deionized water, analytically pure acetone and analytically pure ethanol for 5 minutes each, and then dried with nitrogen for 5 minutes;

[0041] 1b) Immerse the surface-pretreated substrate in a 5M HCl solution for 3 minutes for surface activation, then rinse the sample several times with deionized water and put it into an electrolytic cell.

[0042] Step 2, electroplating a Zn thin film on the foamed Ni substrate.

[0043] 2a) In the electrochemical three-electrode test system, the foam Ni substrate is set as the working electrode, the saturated calomel SCE electrode is the reference electrode, and the metal platinum sheet is the auxiliary electrode, and these three electrodes are placed in the electrolytic cell;

...

Embodiment 2

[0054] Example 2: Preparation of nanoporous Au-Cu alloy material.

[0055] In step 1, substrate pretreatment is performed on the foamed Au-Cu alloy.

[0056] The process of this step is the same as Step 1 of Embodiment 1.

[0057] Step 2, electroplating a Cu thin film on the foamed Au-Cu alloy.

[0058] 2.1) In the electrochemical three-electrode test system, the foamed Au-Cu alloy is set as the working electrode, the Ag / AgCl electrode is used as the reference electrode, and the platinum plate electrode is used as the auxiliary electrode, and these three electrodes are placed in the electrolytic cell;

[0059] 2.2) Configure the mixed solution as the electroplating solution, and its component is 0.5M H 2 S0 4 and 0.2M CuS0 4 , pour the configured solution into the electrolytic cell;

[0060] 2.3) In the test system, take the Ag / AgCl electrode as the reference electrode, set the deposition potential to -0.15V, set the deposition time to 5min, and plate copper on the foamed...

Embodiment 3

[0069] Example 3: Preparation of nanoporous Ag-Au-Cu alloy material.

[0070] Step A, performing substrate pretreatment on the foamed Au-Ag alloy.

[0071] The process of this step is the same as Step 1 of Embodiment 1.

[0072] Step B, electroplating a Cu thin film on the foamed Au-Ag alloy substrate.

[0073] B1) In the electrochemical three-electrode test system test system, the Ag-Au alloy substrate is set as the working electrode, the reference electrode is the saturated calomel SCE electrode, and the metal platinum sheet is the auxiliary electrode, and these three electrodes are placed in the electrolytic cell;

[0074] B2) configuration mixed solution is as electroplating liquid, and its component is the CuS of 0.35M. 4 .5H 2 0 and 0.4M of HB0 3 , pour the configured solution into the electrolytic cell;

[0075] B3) In the test system, take the saturated calomel SCE electrode as the reference electrode, set the deposition voltage to -0.9V, set the deposition time t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com