Glass corrosion mask layer method

A technology of glass and mask, applied in the field of micromachining of mechanical systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

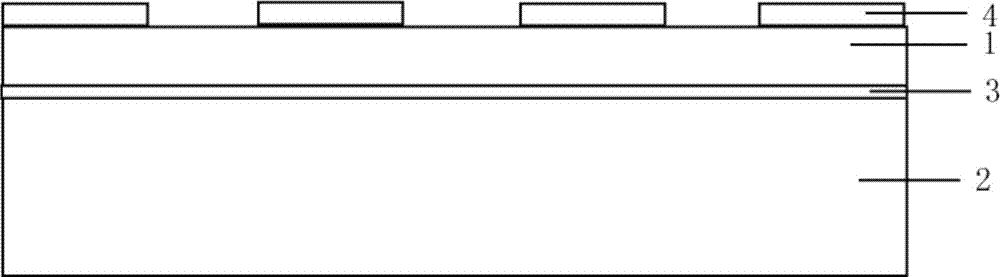

[0039] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] The material used is an N-type silicon wafer with a thickness of 300 μm, a resistivity of 1~10Ω / cm, and a crystal orientation; the glass is 7740 glass with a thickness of 500 μm.

[0041] The masking method of the present embodiment, its steps are as follows:

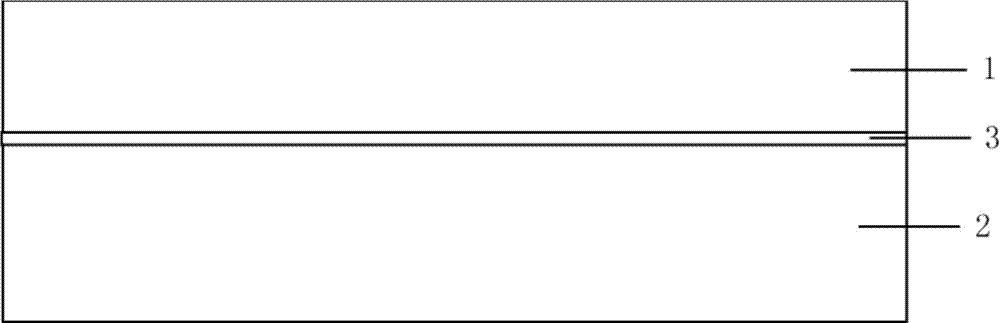

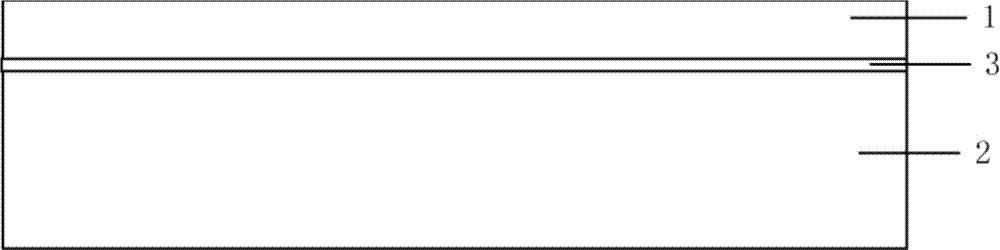

[0042] (1) if figure 1 As shown, the glass 2 and the silicon wafer 1 are bonded by the method of hydroxide catalyzed bonding, specifically:

[0043] (a) Clean the silicon wafer 1 and the glass 2 with a mixture of sulfuric acid and hydrogen peroxide;

[0044] (b) Oxidize the silicon wafer 1 in an oxidation furnace, and the thickness of the oxide layer 3 is 1 μm;

[0045] (c) Drop KOH aqueous solution on the glass 2, the ratio is 1:128, and the drop volume is 0.4 μL / cm 2 ;

[0046] (d) Gently press the silicon wafer 1 with the oxide layer 3 on the glass 2 on the side dripping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com