Fuel subassembly fixing device of reloadable liquid heavy metal reactor

A liquid heavy metal and fuel assembly technology, which is applied in the assembly of fuel elements, climate sustainability, and greenhouse gas reduction, etc., can solve the problems of high buoyancy, large safety impact, poor stability, etc. Stress, strengthen the effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

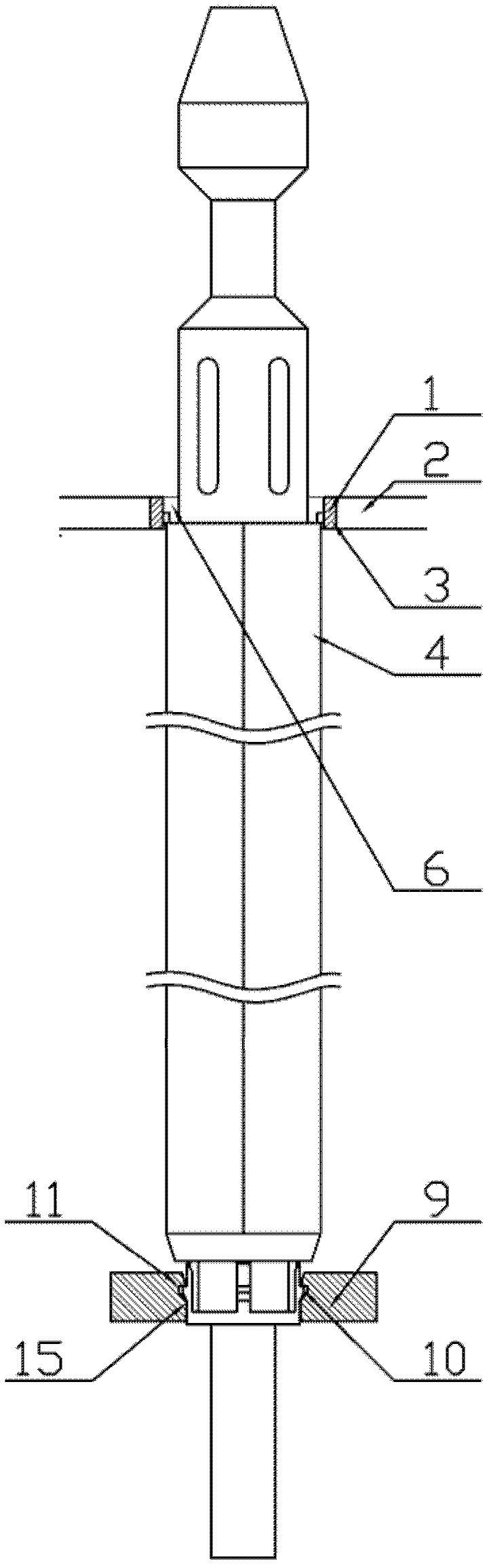

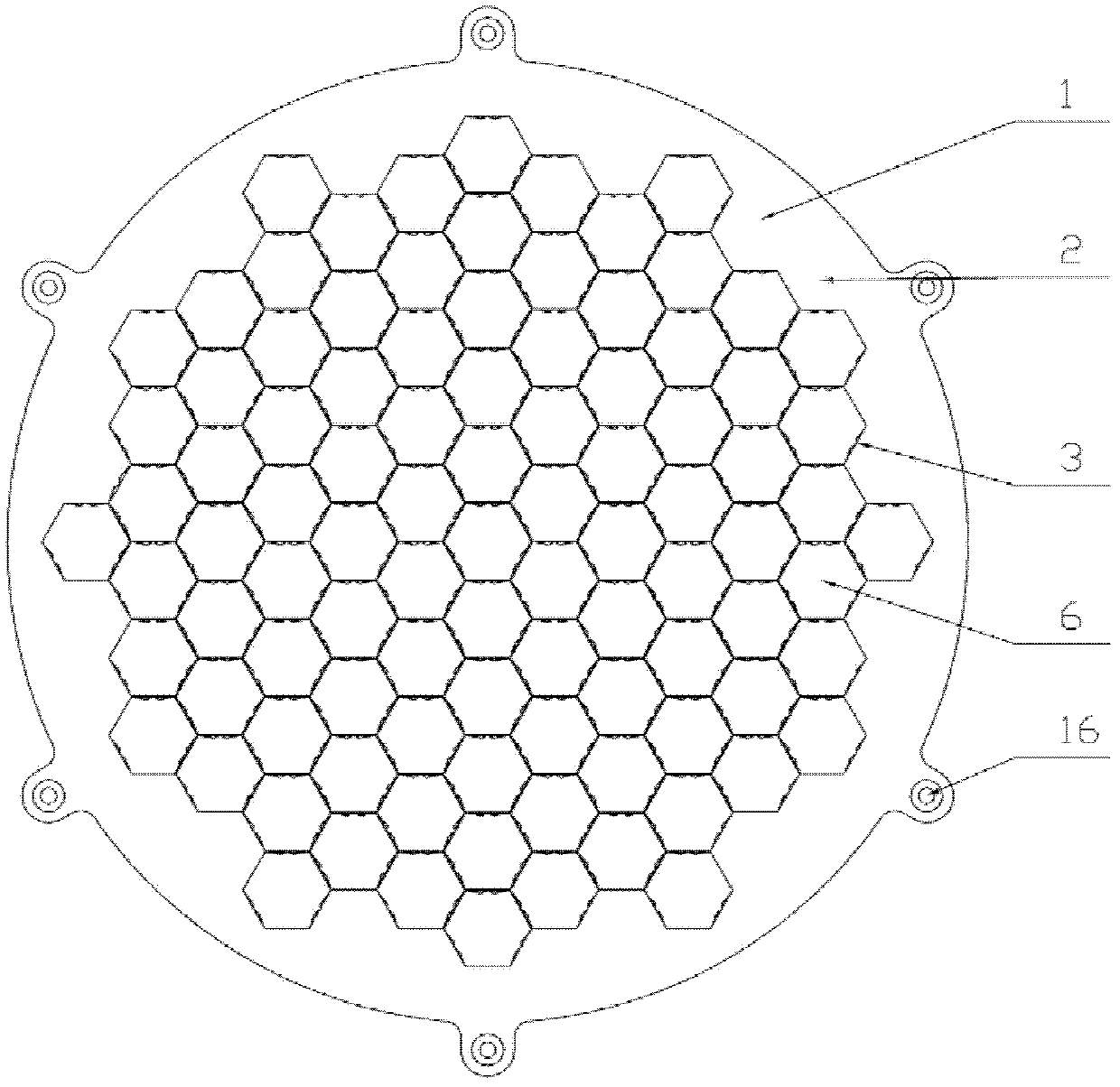

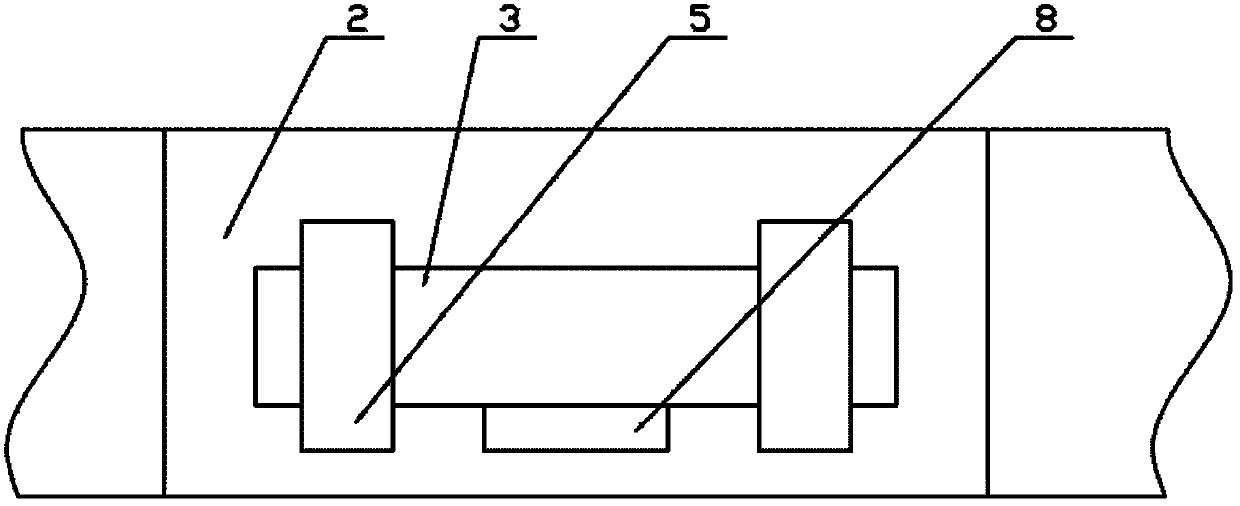

[0022] Such as figure 1 As shown, from the relative positions between the fuel assembly 4 and the upper core grid 1 and the lower core grid 9, it can be known that the upper part of the fuel assembly 4 is in contact with three springs 3 in each hexagonal cell 6. Under relatively high conditions (that is, large thermal expansion and deformation), the three springs 3 provide axial positioning for the assembly, withstand the vibration of the fuel assembly 4 in the stack due to the flow of coolant, and prevent the axial movement of the fuel assembly 4 The 4 metal buttons 10 of the lower pins of the fuel assembly 4 slide into the annular groove 11 of the mounting hole 15 during the loading process of the fuel assembly 4. face support. In the refueling condition, the refueling operation machine grabs the fuel assembly operating head, and the rest of the mechanical structure pushes the spring 3 out of the range of the fuel assembly 4, and moves the fuel assembly 4 down until the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com