Dual-layer pipe wall composite-type gas pipeline and leakage monitoring method

A gas pipeline and composite technology, applied in the pipeline system, fluid tightness test, pipe/pipe joint/pipe fitting, etc., can solve the problems of gas leakage, difficult to identify the leakage point, small leakage, etc., to avoid fire and explosion , save the cost of manual line inspection, and prevent the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing:

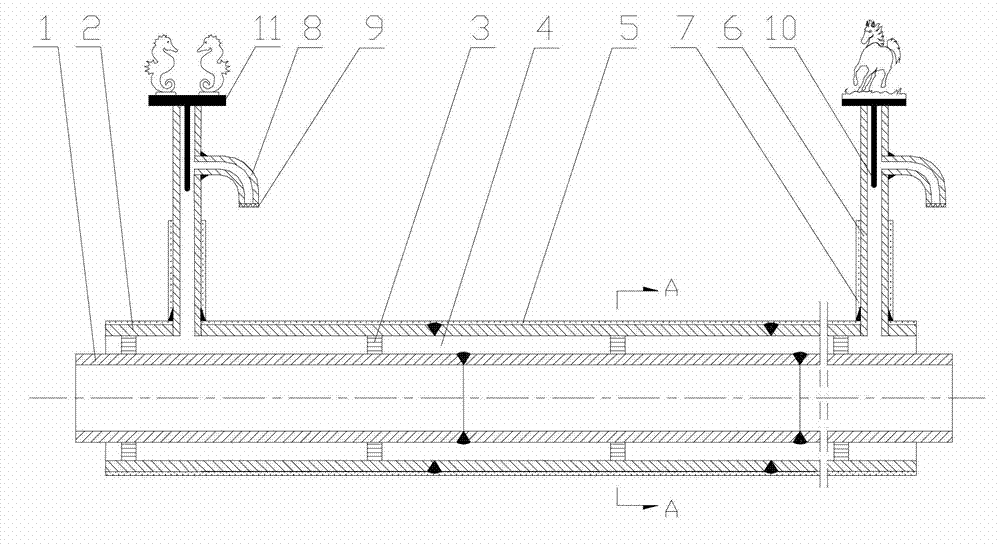

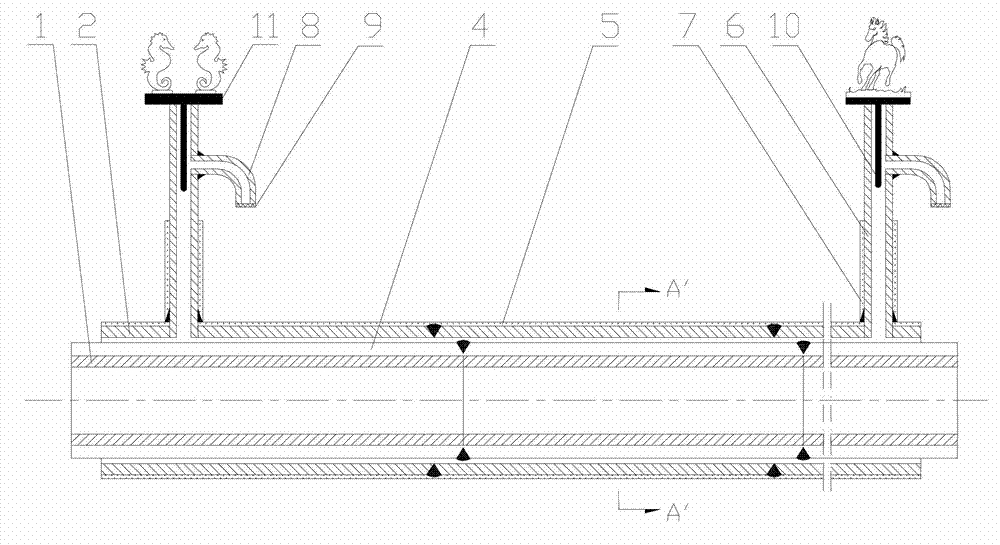

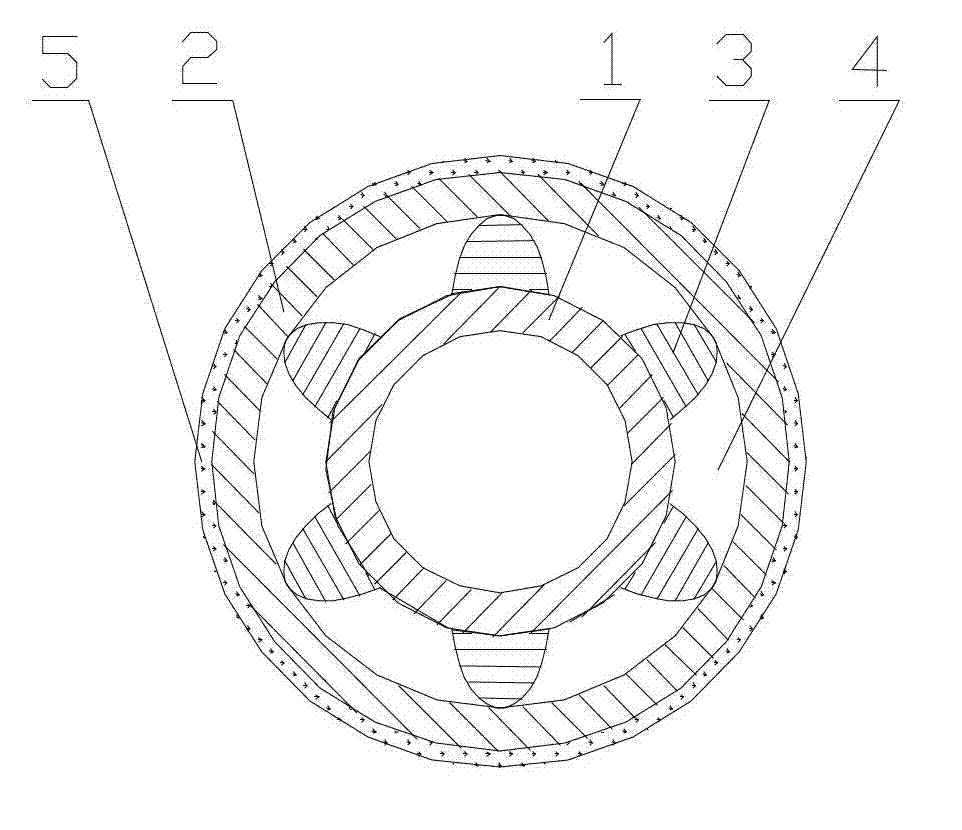

[0067] figure 1 One embodiment of the invention is shown. This kind of composite gas pipeline with double-layer pipe wall includes an inner pipe 1 and an outer pipe 2. Support sheet 3, thus forming a gap cavity 4 between the inner tube 1 and the outer tube 2, nitrogen replacement is carried out in the gap cavity 4, the outer circumference of the outer tube 2 is wrapped with an anti-corrosion material layer 5, and the top of the side wall of the outer tube 2 is provided with A number of vertical branch pipes 6 communicating with the gap cavity 4, the vertical branch pipes 6 are 40-60m apart from each other and the top is at least 80cm above the ground, a concrete slab 11 is arranged at the top of each vertical branch pipe 6 for sealing, and the bottom surface of the concrete slab 11 A combustible gas probe 10 is installed, and the combustible gas probe 10 extends into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com